Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Liquid solid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

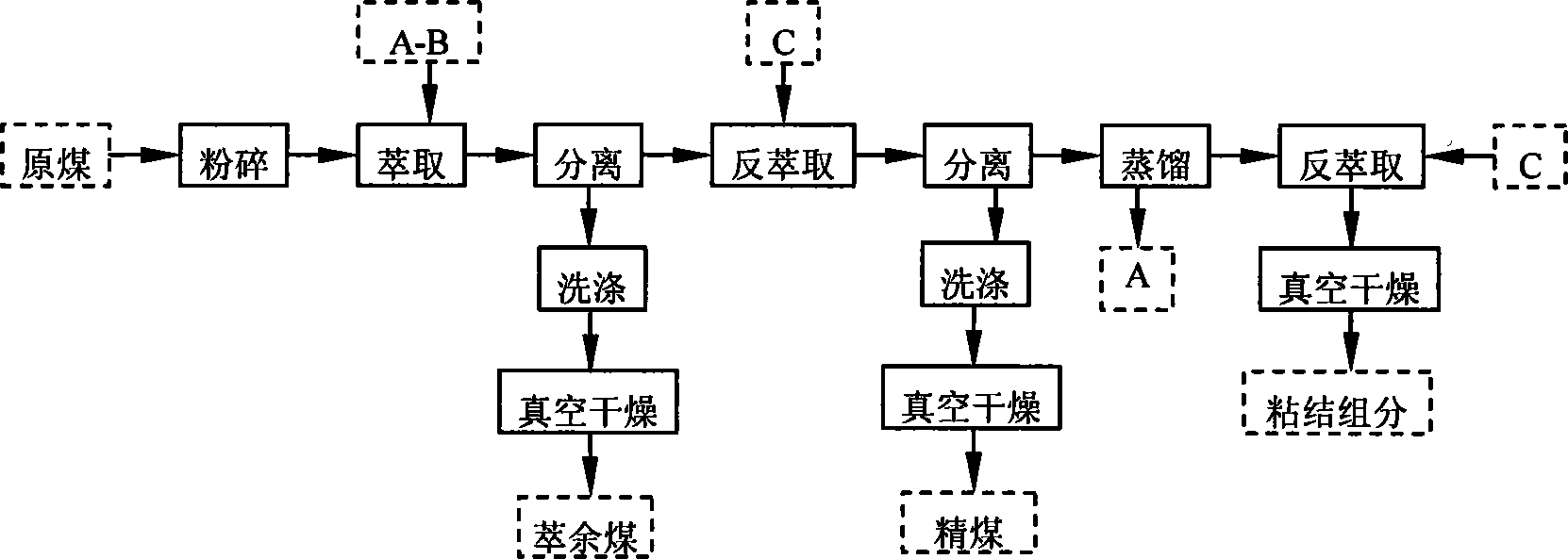

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

Fibers capable of heat storage and temperature adjustment

InactiveCN101845683AReduce leakageImprove thermal stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterCore component

Owner:YINGBAO FIBER TECH RENHUA

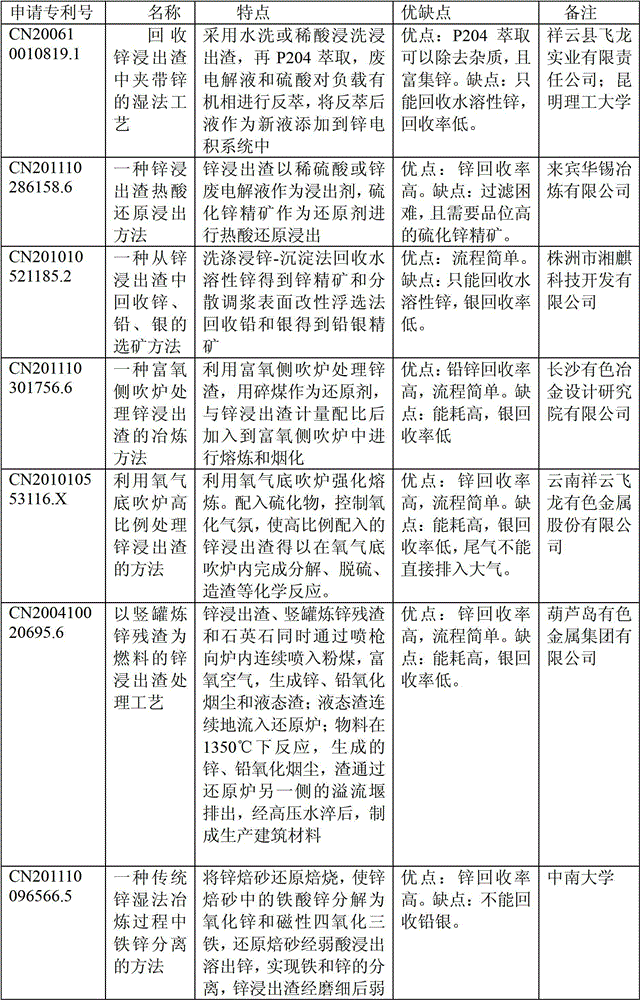

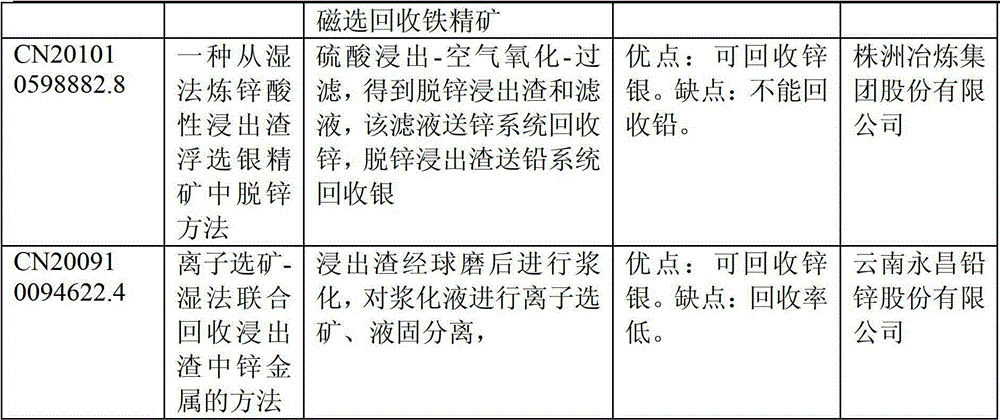

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

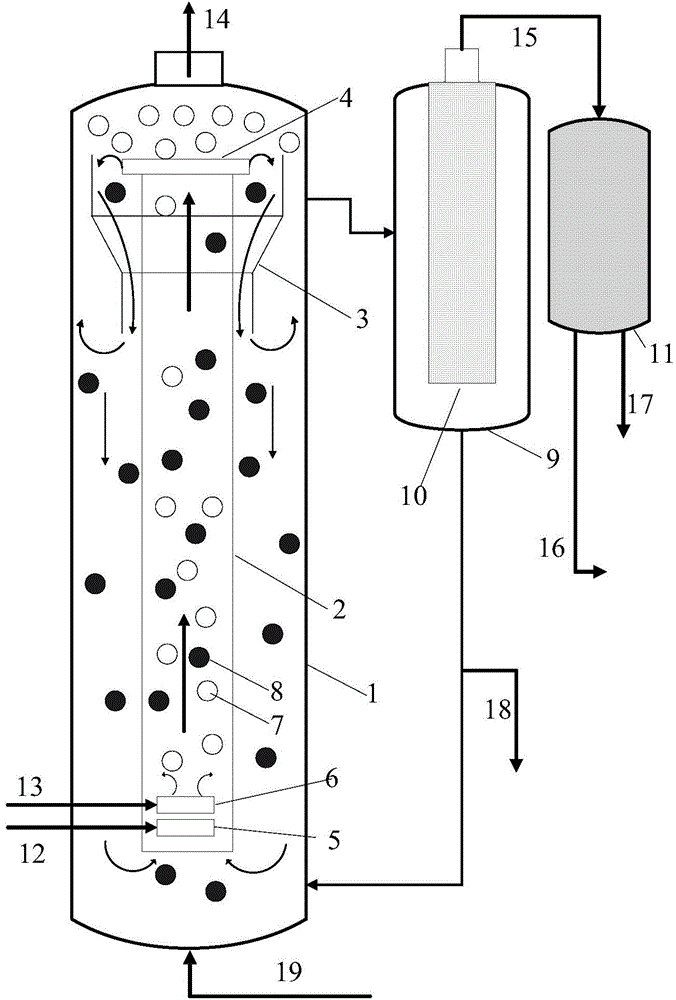

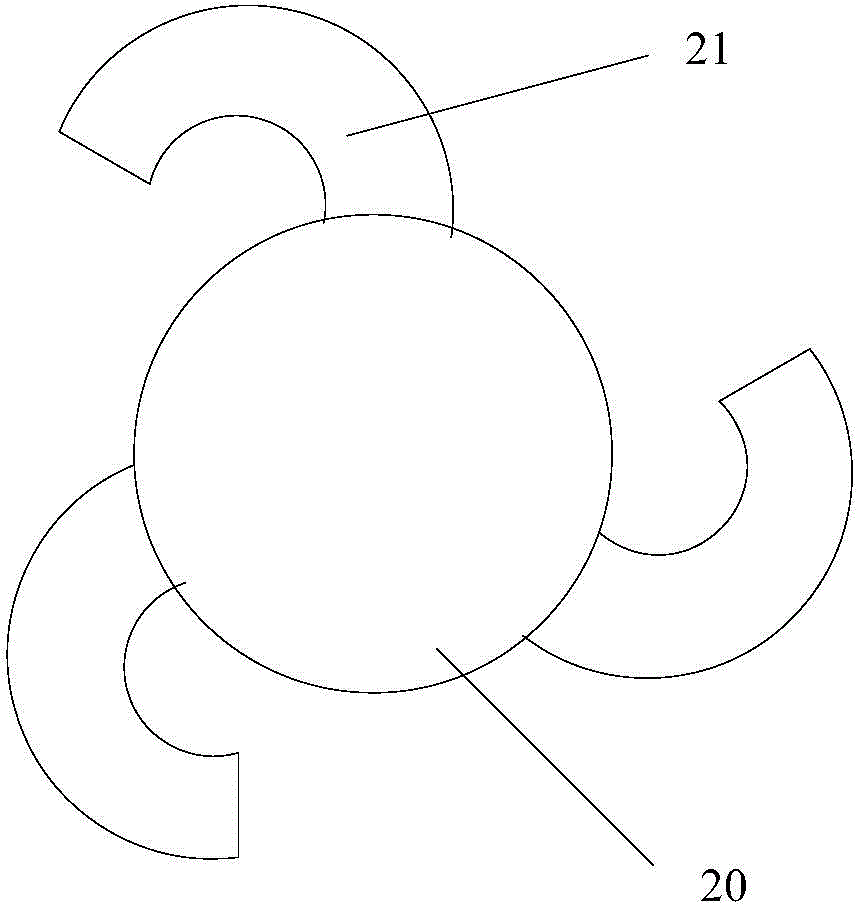

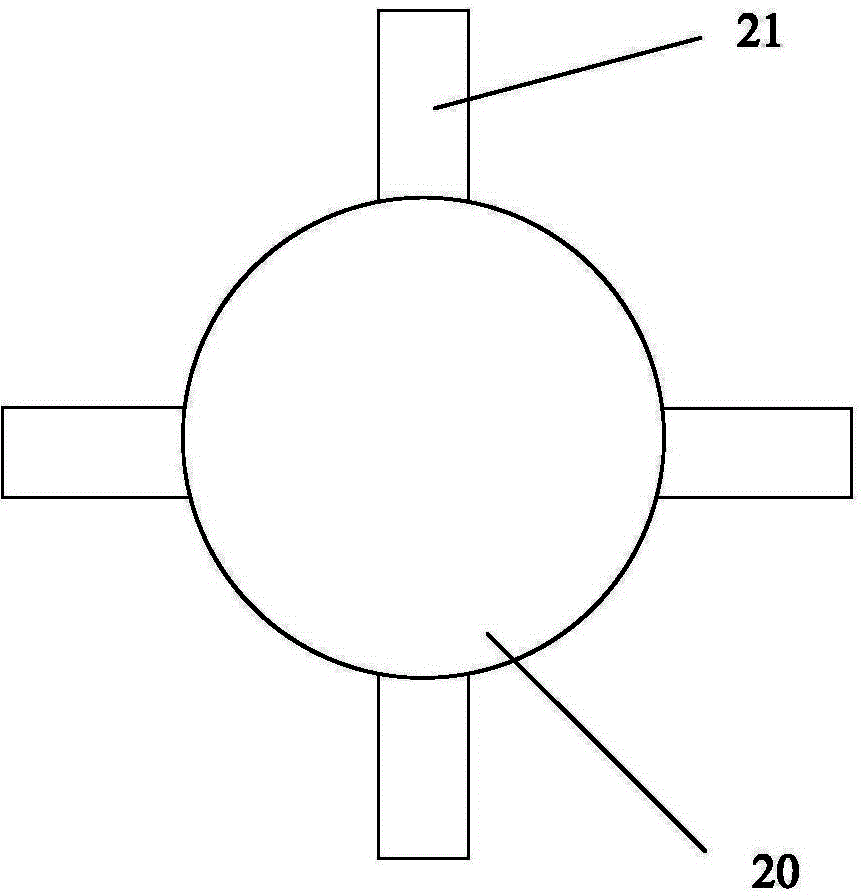

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

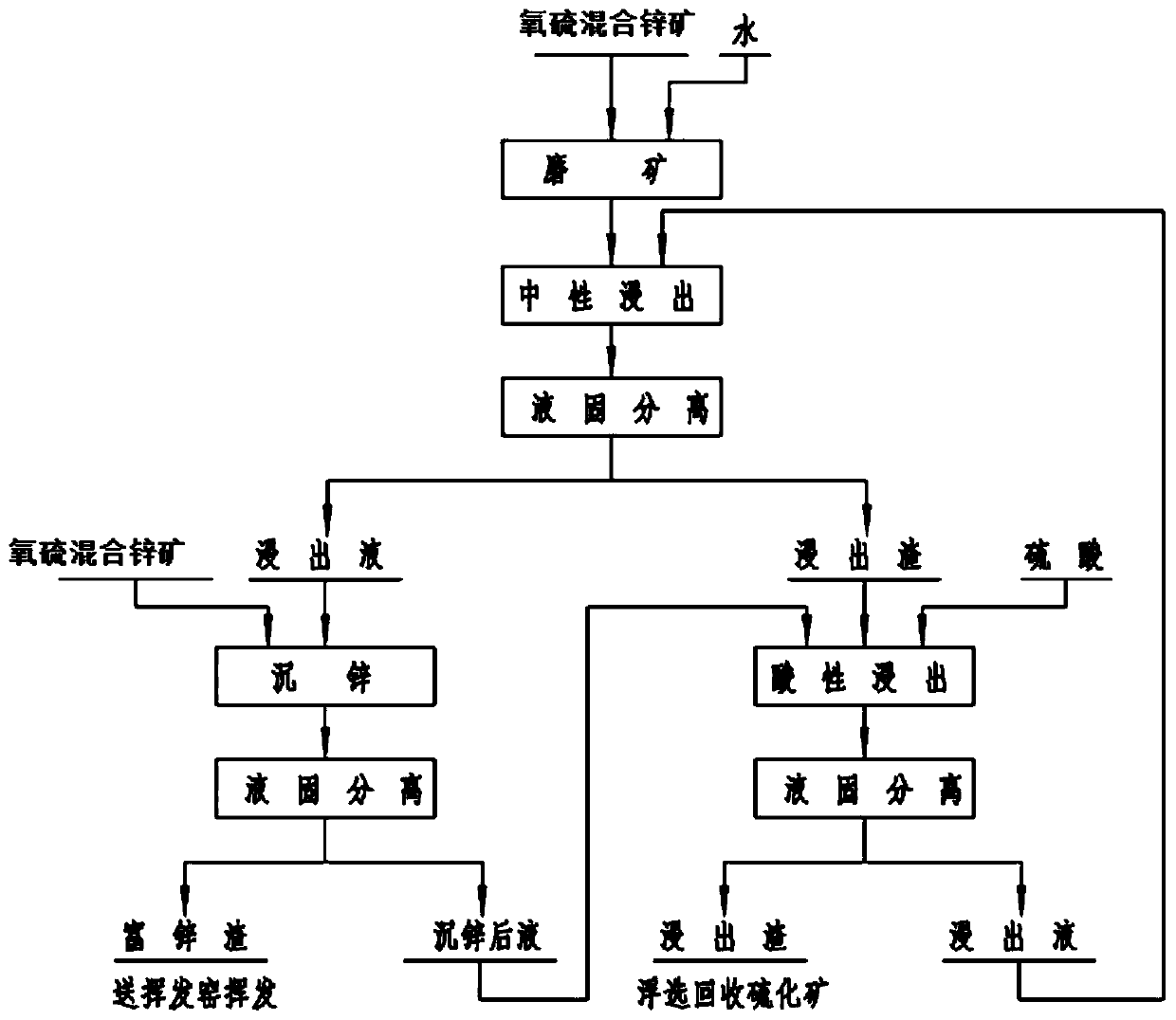

Method for secondarily enriching zinc from low-grade high-oxidization-rate oxygen-sulfur mixed zinc ore

ActiveCN110157924AImprove leaching efficiencyImprove leaching rateProcess efficiency improvementPregnant leach solutionSulfur

Owner:CINF ENG CO LTD

Method for producing chromate by liquid-phase catalytic oxidation of chromite

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

E-cigarette solid powder

InactiveCN108143008AIncrease aromaGood for healthTobacco devicesAdditive ingredientElectronic cigarette

Owner:宁波华纳博锐电子科技有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap