Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Screed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Screed has three meanings in building construction: 1) a flat board (screed board, floating screed) or a purpose-made aluminium tool used to smooth and true materials like concrete, stucco and plaster after it has been placed on a surface or to assist in flattening; 2) a strip of plaster or wood applied to a surface to act as a guide for a screed tool (screed rail, screed strip, screed batten); 3) the material itself which has been flattened with a screed (screed coat). In the UK, screed has also come to describe a thin, top layer of material (traditionally sand and cement), poured in site on top of the structural concrete or insulation, on top of which other finishing materials can be applied, or it can be left bare to achieve a raw effect.

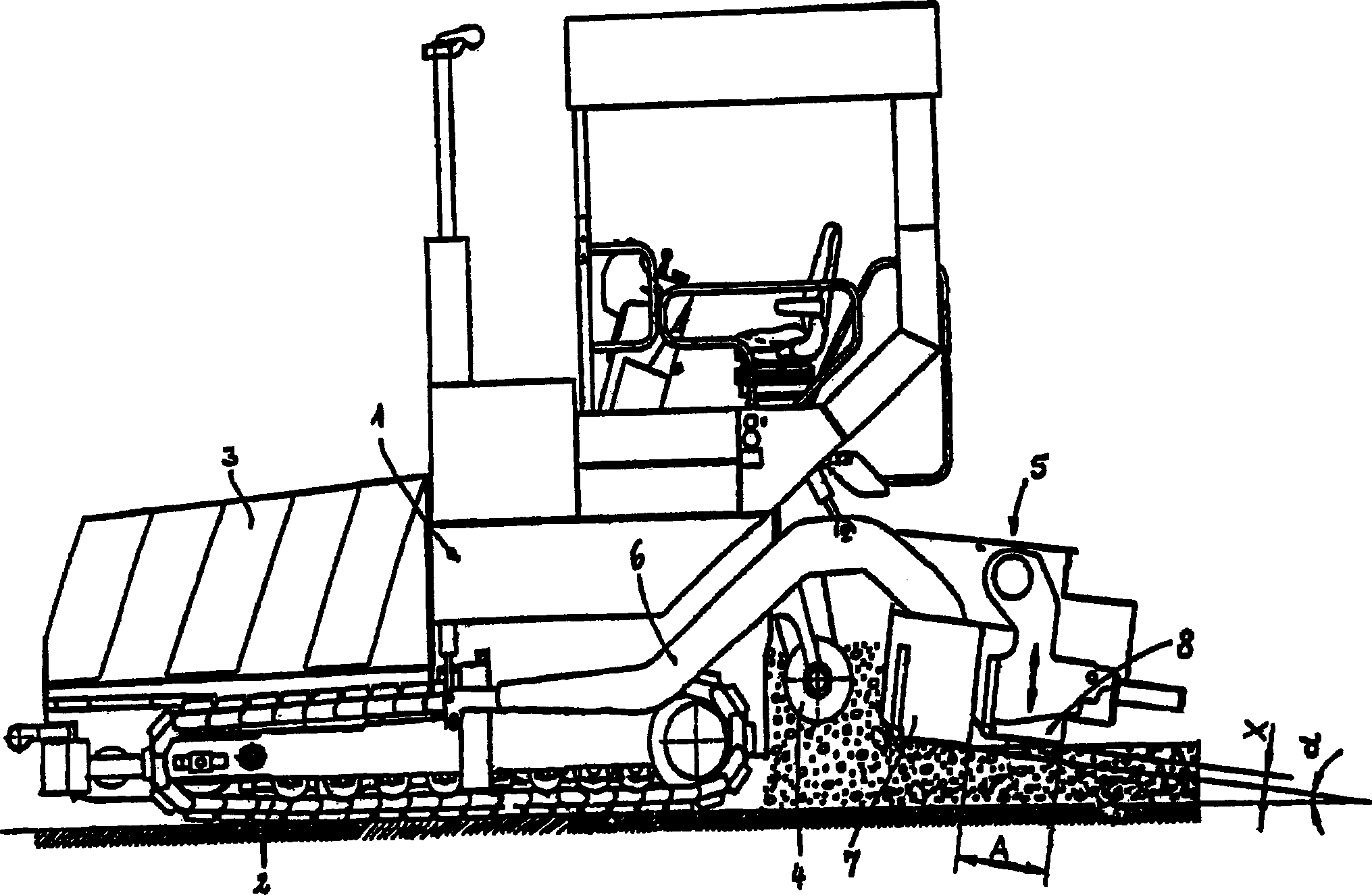

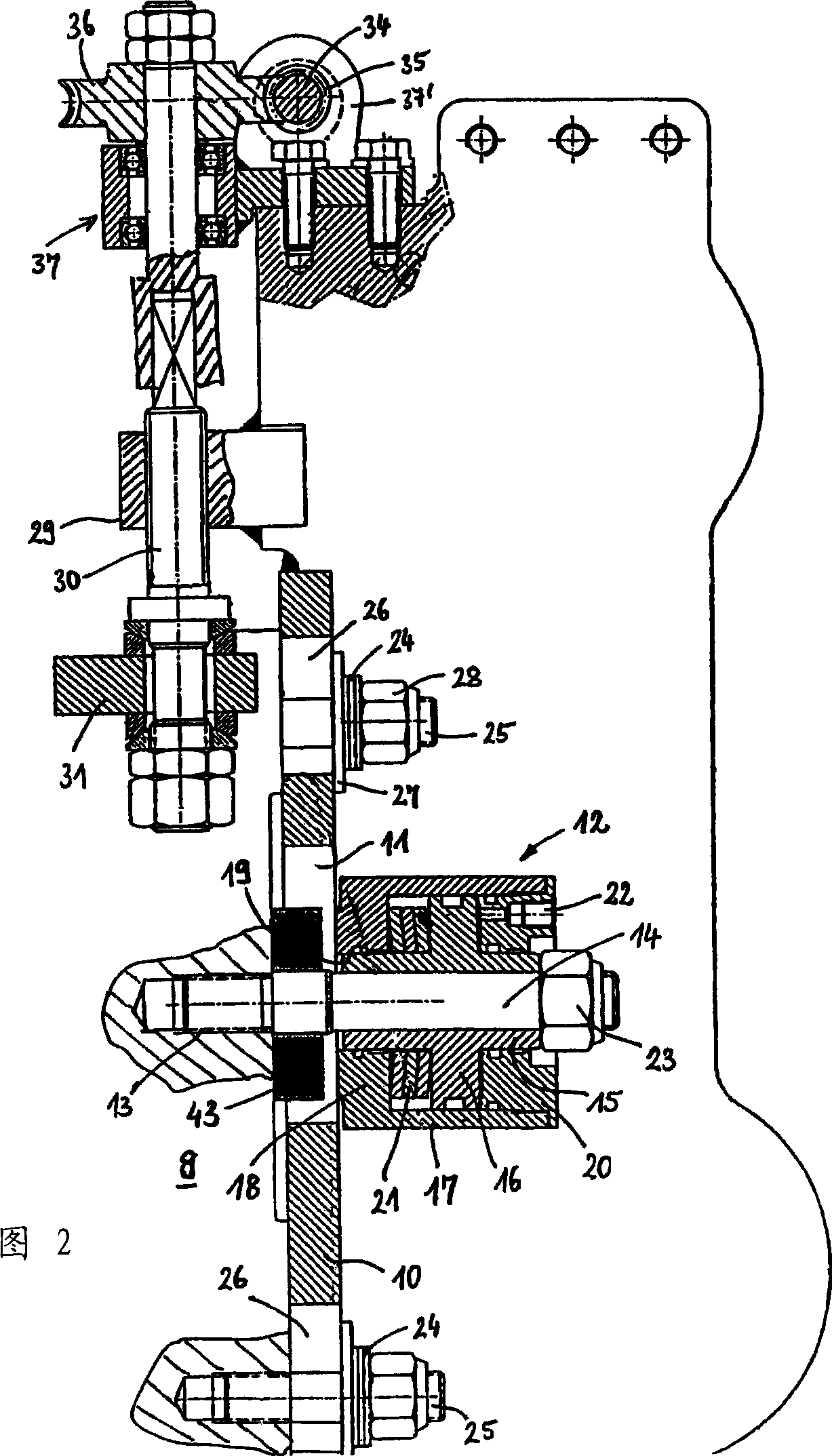

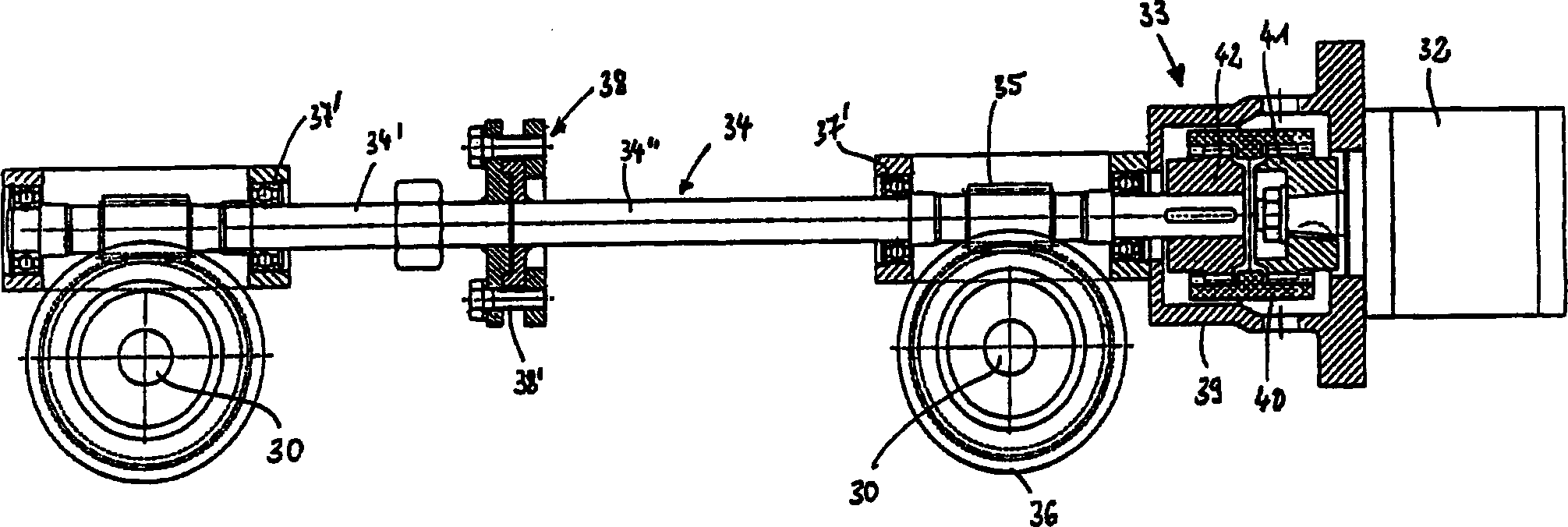

Plate for imparting a smooth finish to freshly-laid paving materials for paver

Owner:ABG ALLG BAUMASCHINEN GMBH

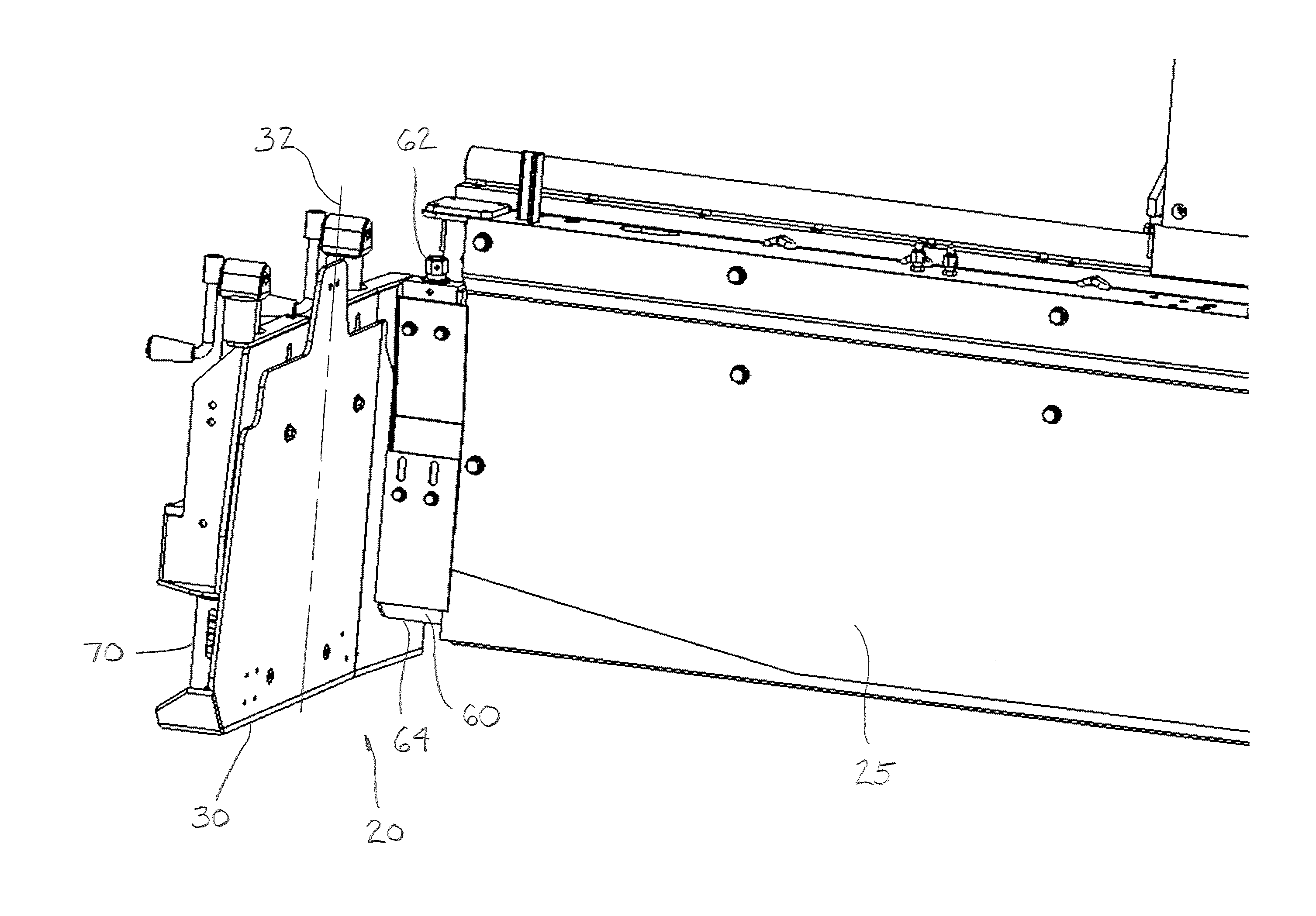

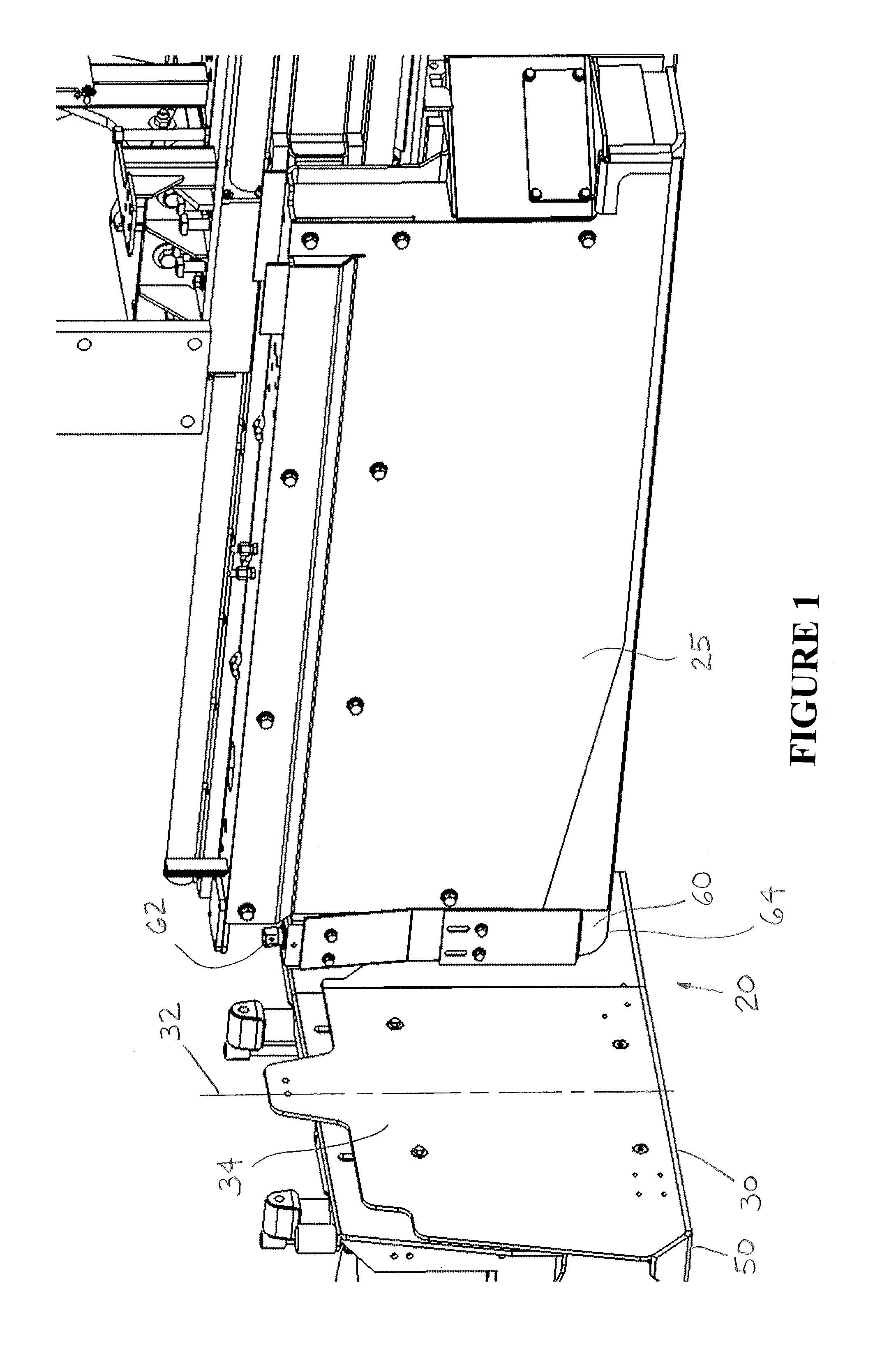

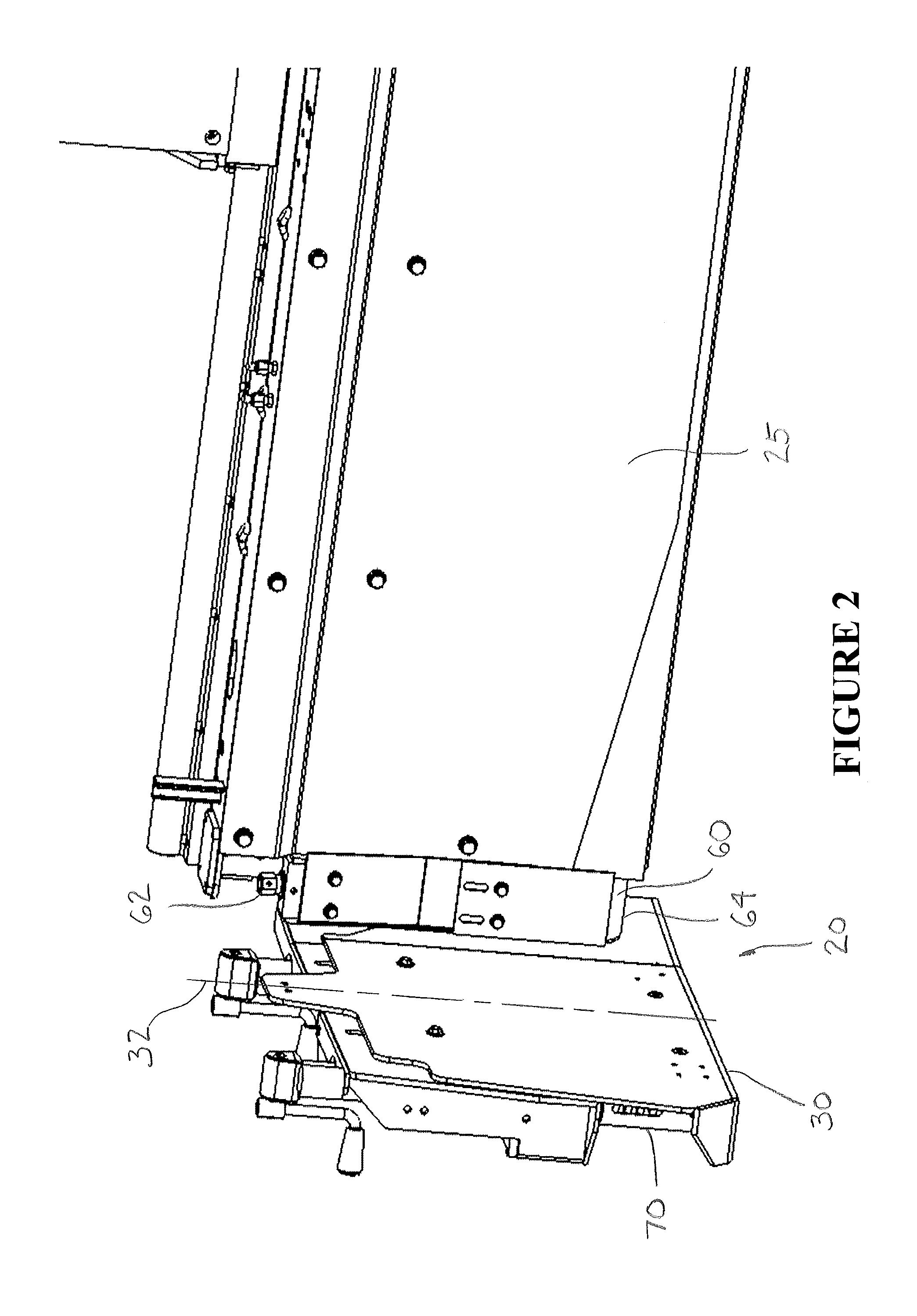

Apparatus and method for a joint density bolt-on assembly

Owner:CARLSON PAVING PRODS

Cordless electrically-powered concrete screed

A power unit is configured for use as part of a concrete screed and includes a frame and a powered drive. The frame includes a drive housing. The powered drive is operably supported by the drive housing and is configured to rotate a rotatable concrete forming drum. The powered drive includes an electric motor and a battery operably coupled to the electric motor and configured to power the electric motor. The powered drive includes a drive shaft drivingly connectable relative to the drum, with rotation of the drive shaft causing corresponding rotation of the drum.

Owner:CURB ROLLER

High-bearing-capacity pavement structure and paving construction method

PendingCN114575212AGuaranteed filling densityAchieving uniformity of distributionPaving reinforcementsIn situ pavingsScreedCrushed stone

The high-bearing-capacity pavement structure comprises a graded broken stone layer, a mortar layer is laid on the graded broken stone layer, a bonding layer is laid on the mortar layer, and an asphalt concrete overlay layer is laid on the bonding layer; a reinforcement cage is arranged in the bonding layer, outer ribs are arranged on the upper side and the lower side of the reinforcement cage, and the outer ribs extend into the mortar layer and the asphalt concrete overlay layer. The paving construction method of the high-bearing-capacity pavement structure comprises the following steps: 1) leveling a site and erecting a template; (2) paving a large-particle-size gravel layer; (3) paving a small-particle-size gravel layer; (4) rolling to form a graded broken stone layer; the construction method comprises the following steps of (1) paving cement mortar to form a gravel grouting layer, (2) mounting a reinforcement cage, (3) paving a bonding layer, (4) paving a bonding layer, and (5) paving cement mortar to form a gravel grouting layer, (6) mounting a reinforcement cage, (7) paving a mortar layer, (8) paving a bonding layer, and (9) paving an asphalt concrete overlay layer.By adopting the structure and the method, the pavement structure is optimized, the stability between layers of pavements is enhanced, the slippage risk of the pavement is reduced, and reliable environmental conditions are provided for normal operation of roads.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

Modular punching-leveling integrated die for ring-shaped flaky powder metallurgy product

InactiveCN107900197ANot easy to produceQuality improvementShaping toolsPerforating toolsScreedPunching

The invention discloses a mold for modular stamping and integration of annular flake powder metallurgy products. It includes an upper mold and a lower mold, the upper mold includes a base, the lower end of the base is fixed with a connecting column, the lower end of the connecting column is fixed with a punching head, and four mounting brackets are uniformly arranged around the base, Two pairs of mounting frames are formed opposite to each other, and a telescopic cylinder is respectively installed at the lower end of each mounting frame. The cylinder body of the telescopic cylinder is connected to the corresponding mounting frame through an elastic connection structure, so that the telescopic cylinder can move up and down. The piston of the telescopic cylinder A leveling head with a semi-circular cross-section is installed on the rod; a distance is left between the upper end surface of the leveling head and the lower end surface of the mounting frame; The blanking hole is located below the positioning hole and communicates with the positioning hole. The diameter of the positioning hole is equal to the outer diameter of the leveling head and the outer diameter of the workpiece. The diameter of the blanking hole is equal to that of the punching head. diameter of.

Owner:CHONGQING WANSHENG SHUNDA POWDER METALLURGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap