Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Shaped beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

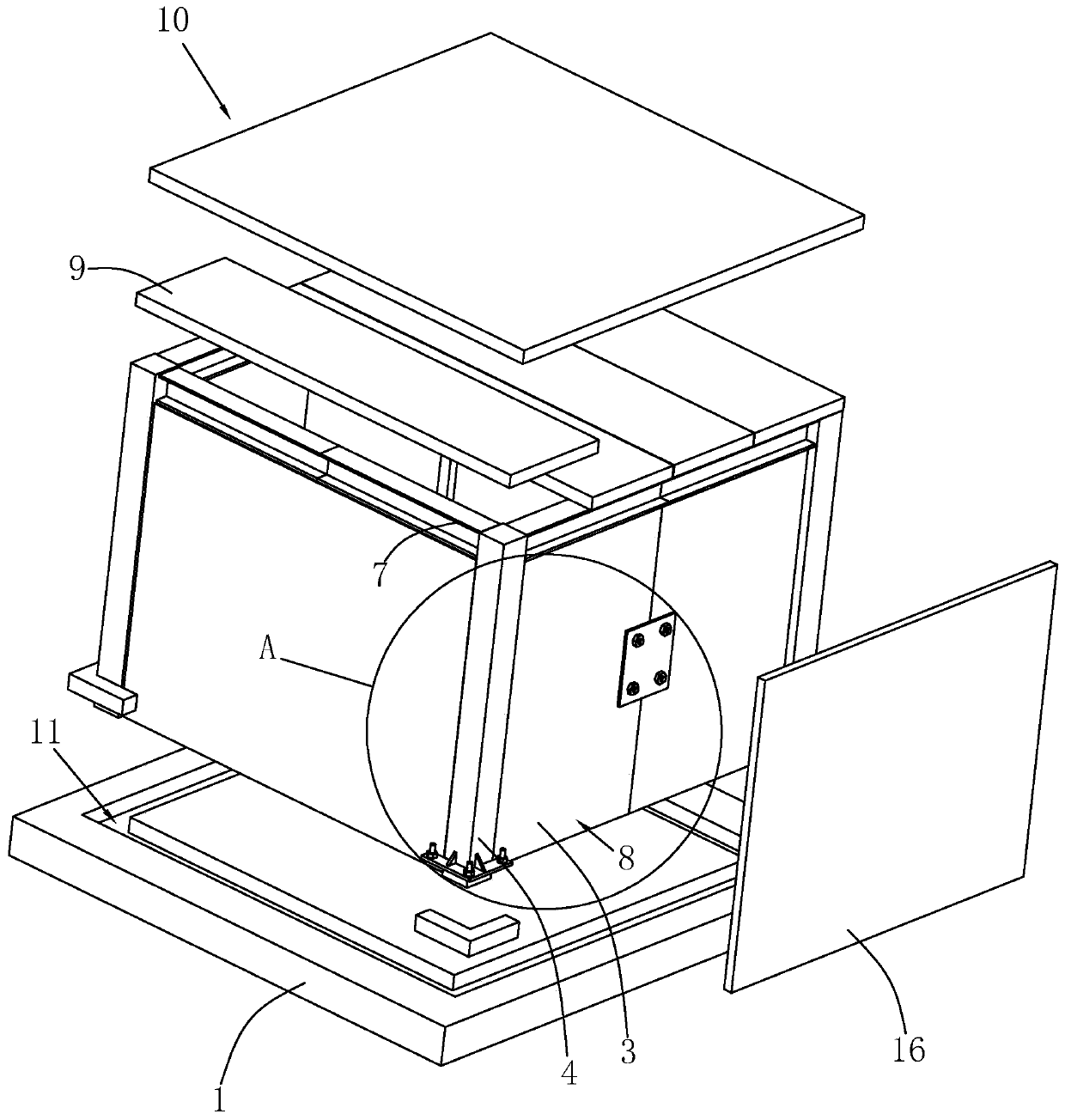

A method of constructing earthquake resistant structure with reinforced foundation and wall structure

Owner:YASHRAJ MAHESH +1

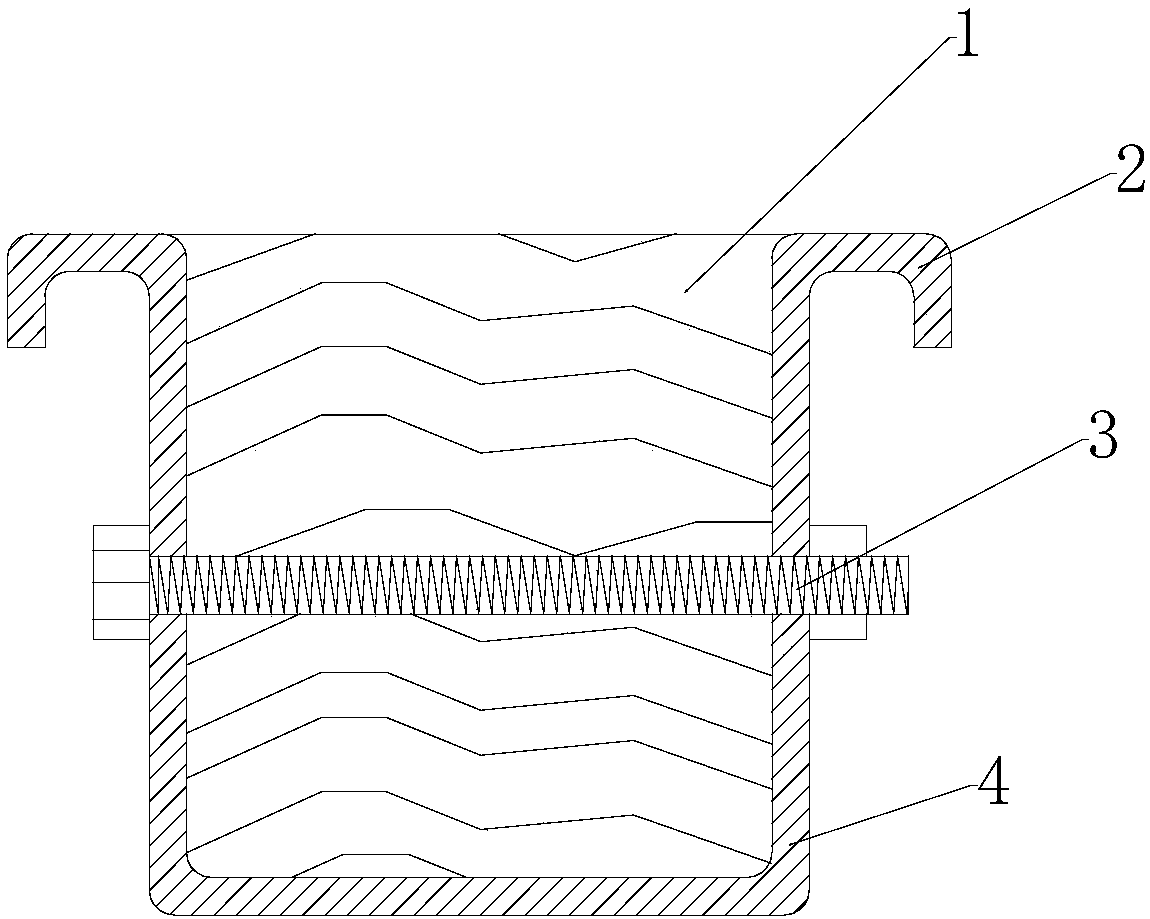

Building keel

InactiveCN108222494AIncrease the moment of inertia of the sectionImprove mechanical performanceForming/stuttering elementsShaped beamKeel

Owner:天津艳丽科技有限公司

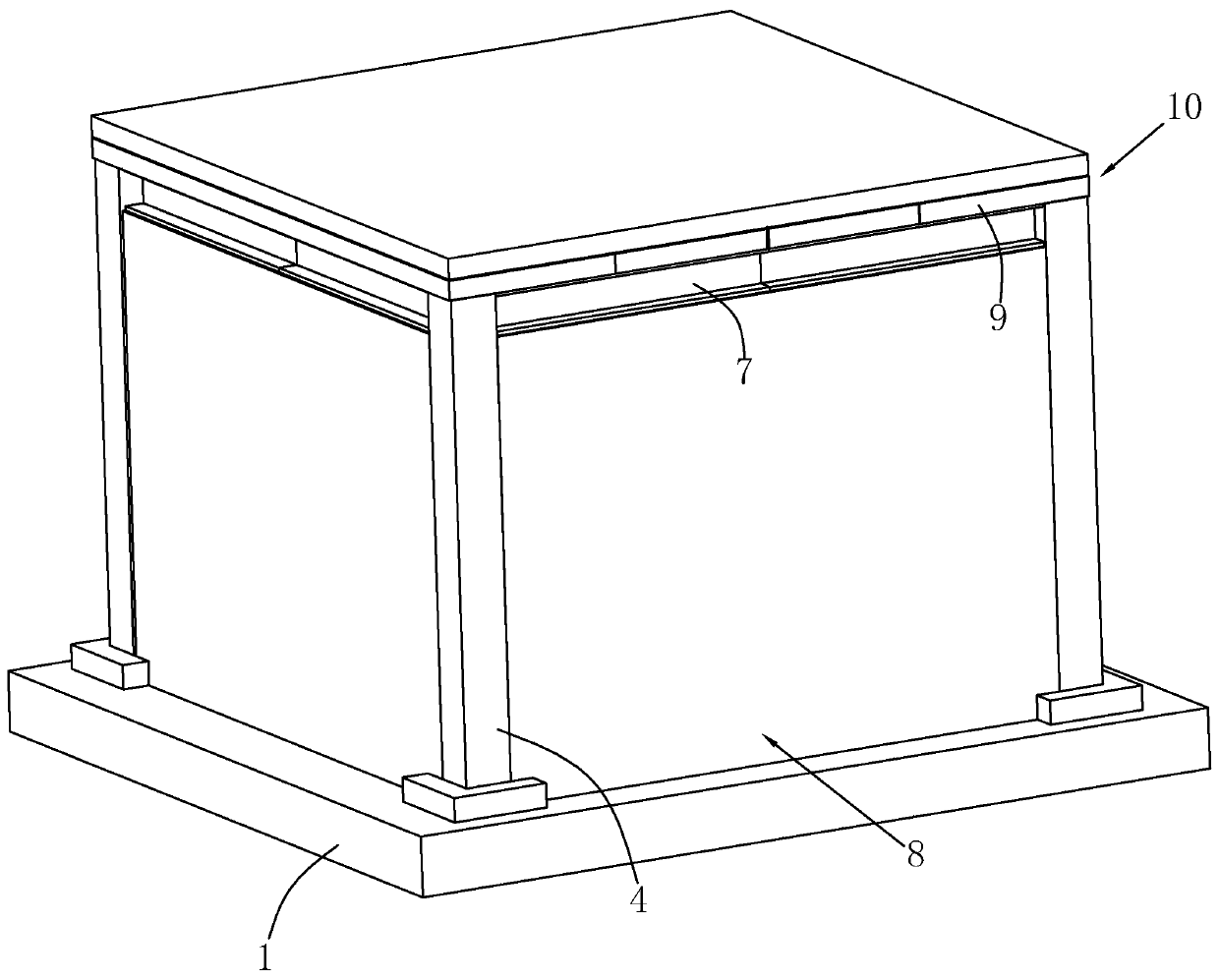

Assembly type concrete component mounting method

InactiveCN111456453ASimplify the production and construction processEasy to installWallsFloorsReinforced concreteShaped beam

Owner:豫通工程管理有限公司

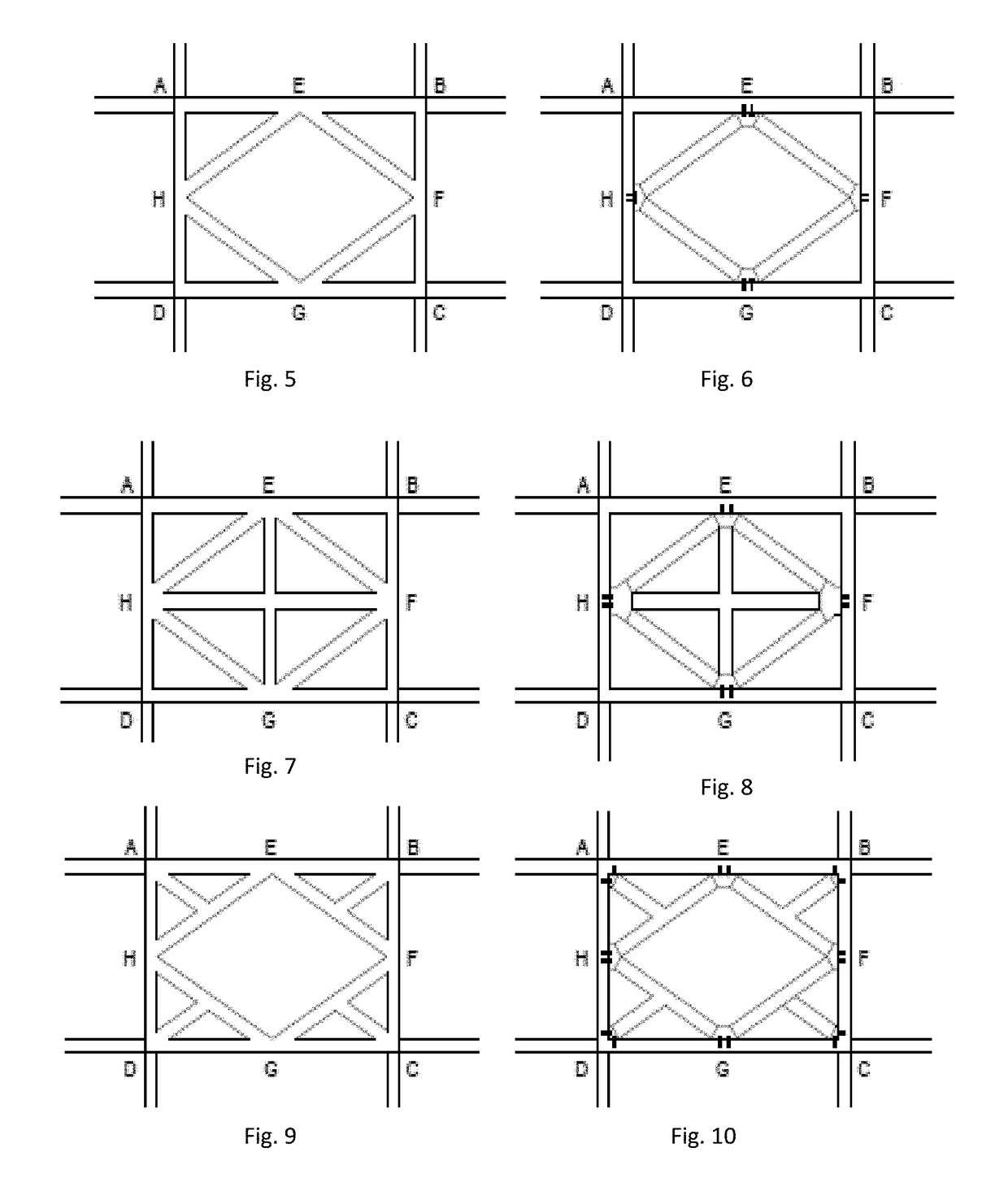

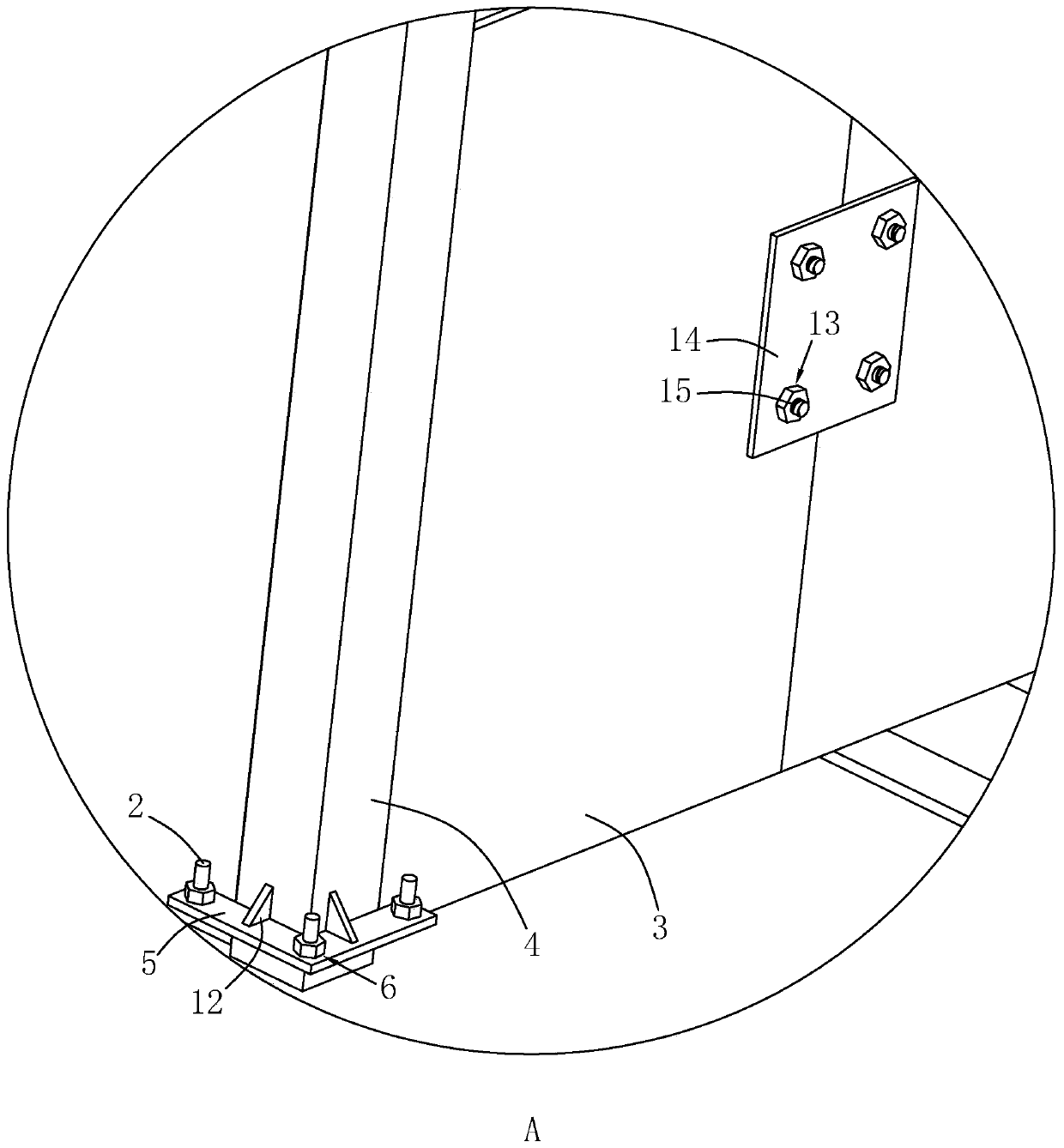

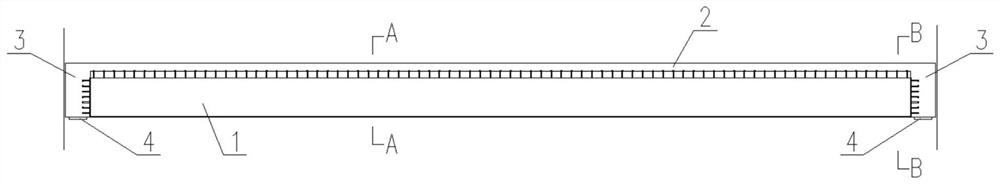

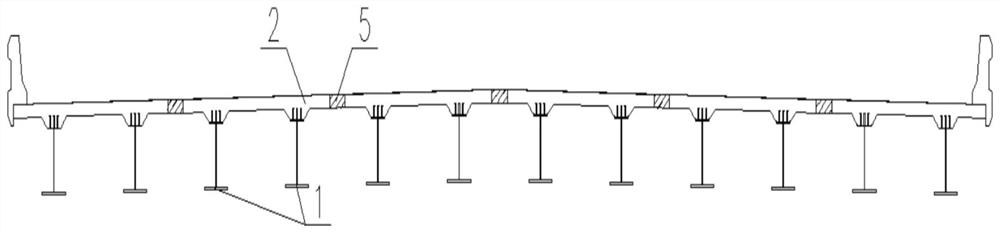

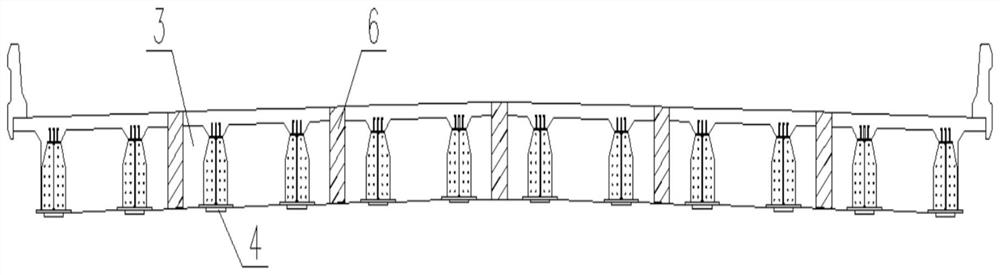

Novel fabricated steel-concrete combined steel plate beam

PendingCN113605213AIncreased durabilityEasy constructionBridge structural detailsBridge materialsShaped beamBridge deck

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap