Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Textile technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile Technology. Textile technology is the processing of a raw material – natural products such as wool and cotton, or synthetics like nylon and acrylics – into yarn, thread and fabric. It involves developing new colors, textures and properties such as water and fire resistance.

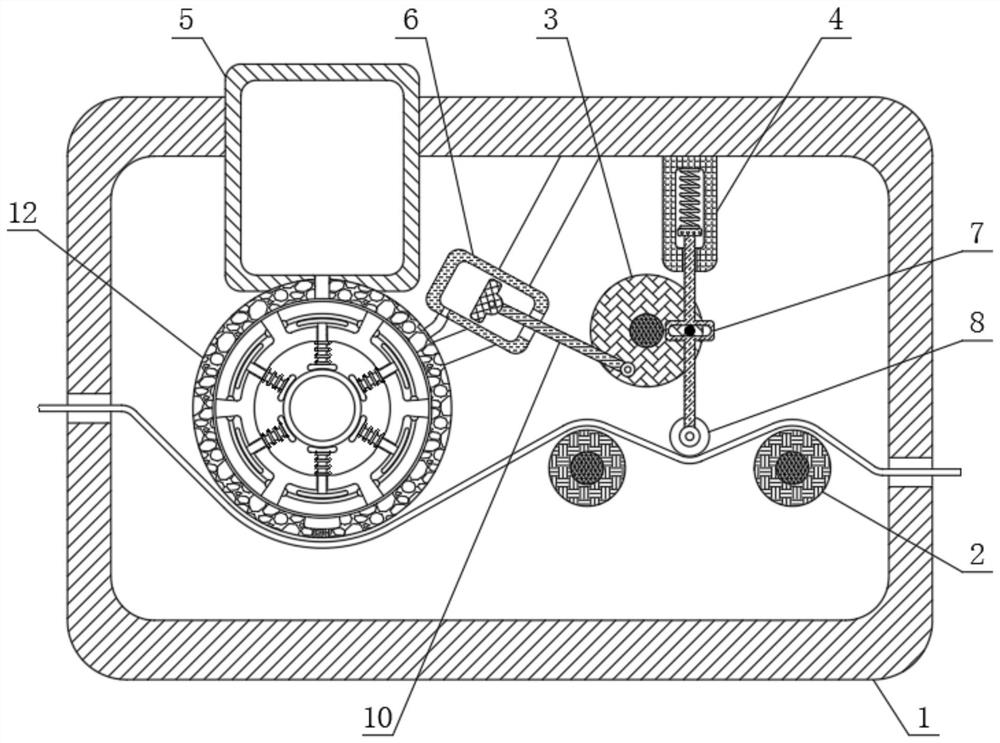

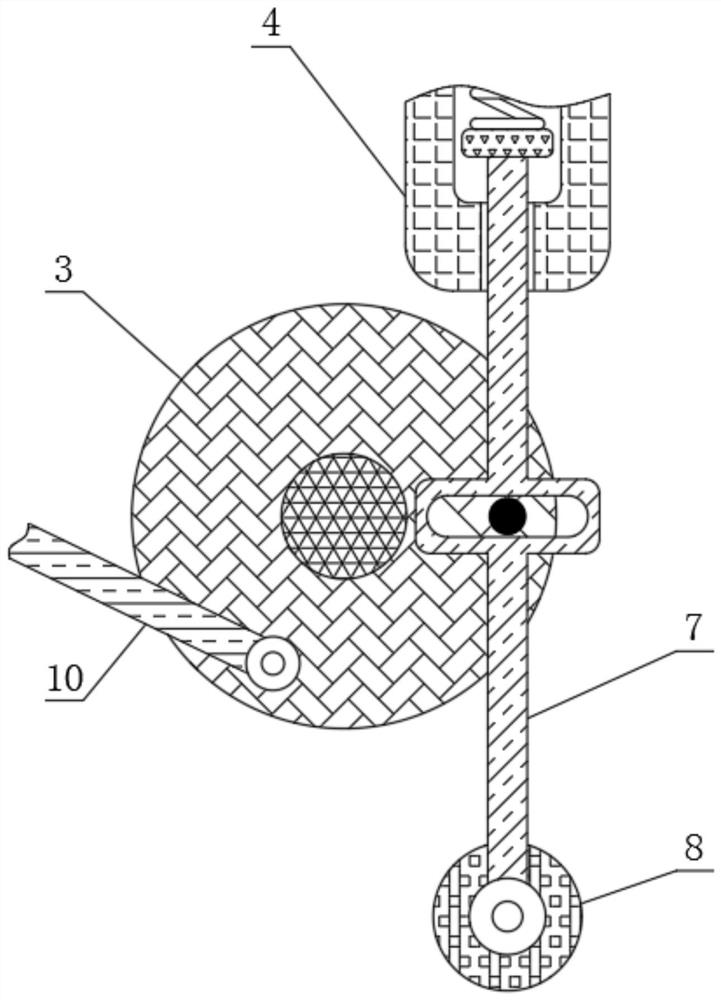

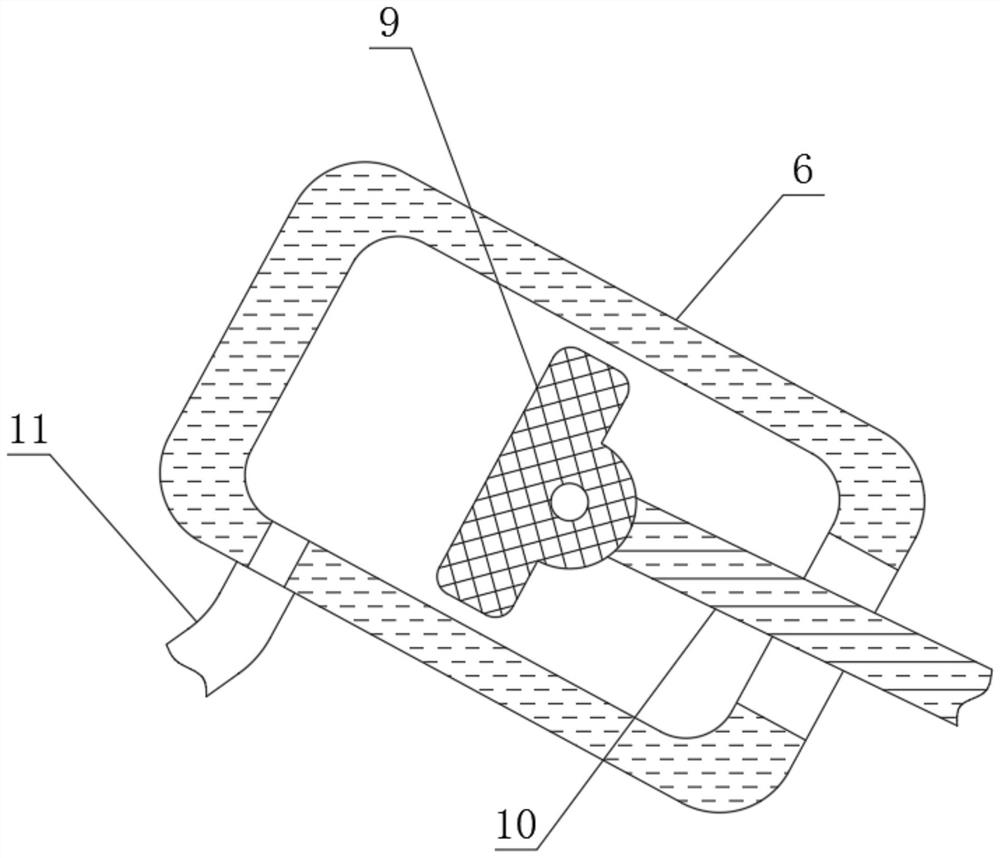

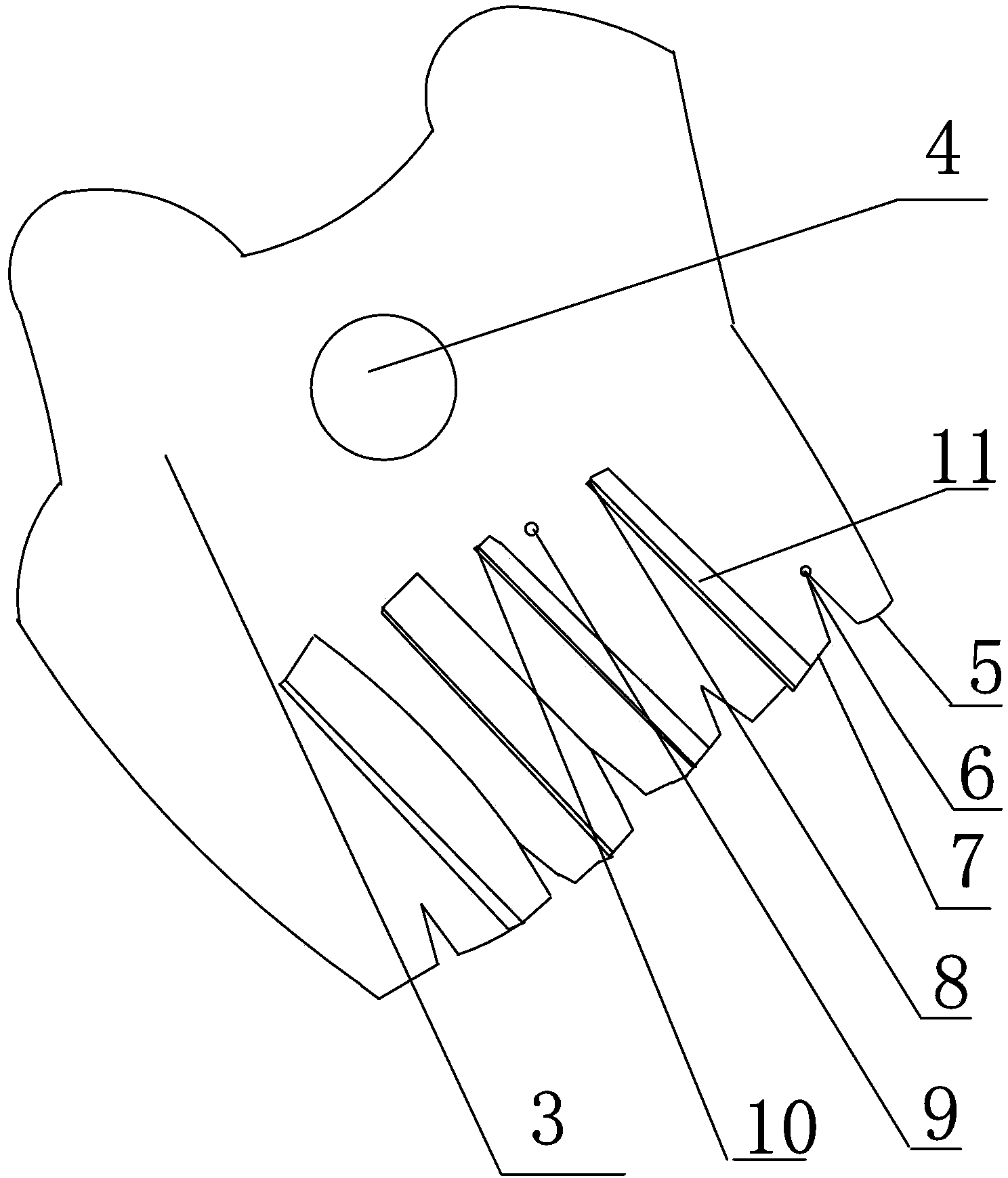

Textile fabric wetting device capable of automatically adjusting water volume according to stretching length of textile fabric

InactiveCN112941762AWet evenlyAutomatically adjust the water volumeLiquid/gas/vapor textile treatmentTextile treatment rollersTextile technologyEngineering

Owner:温州正中服饰有限公司

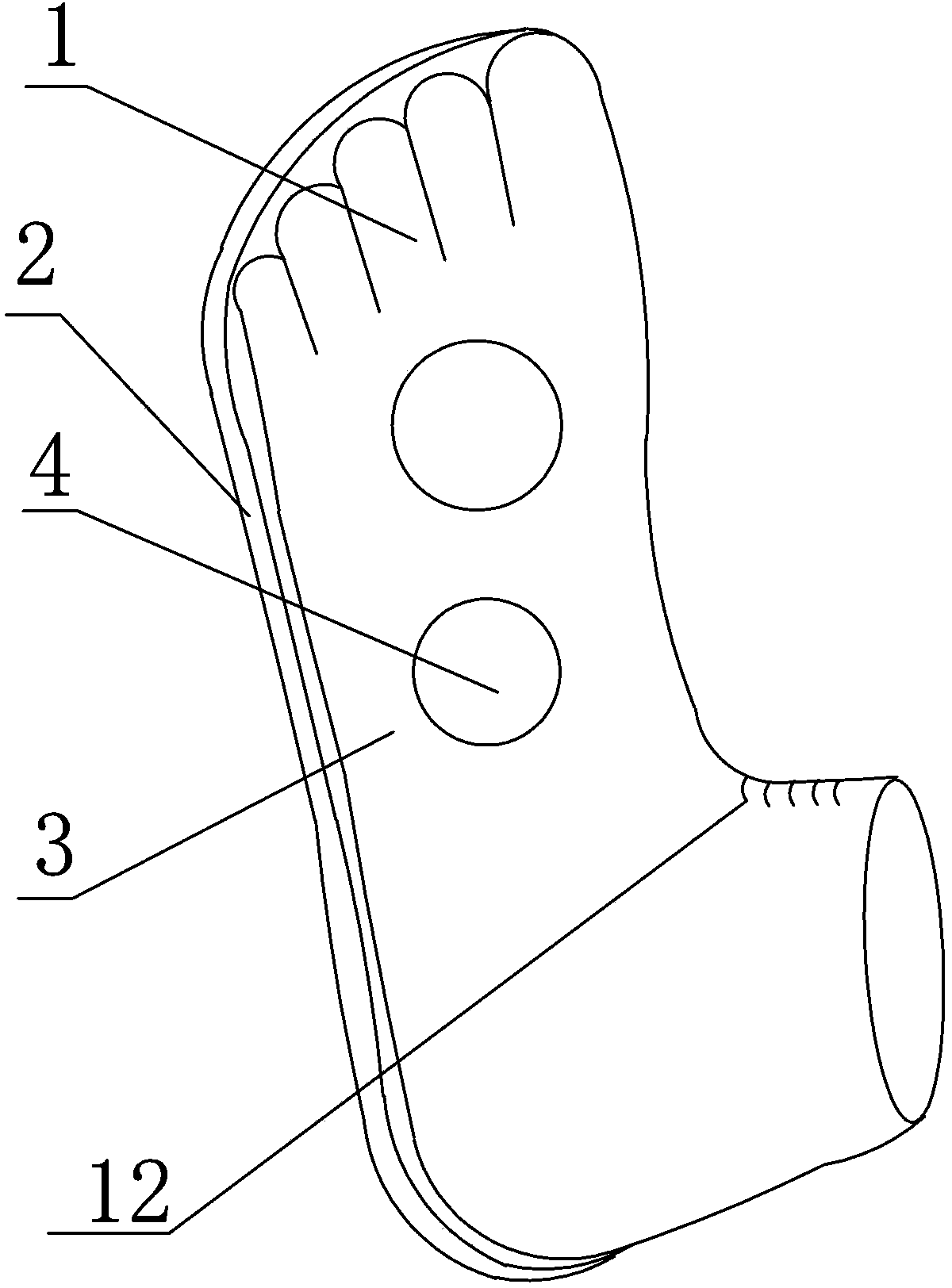

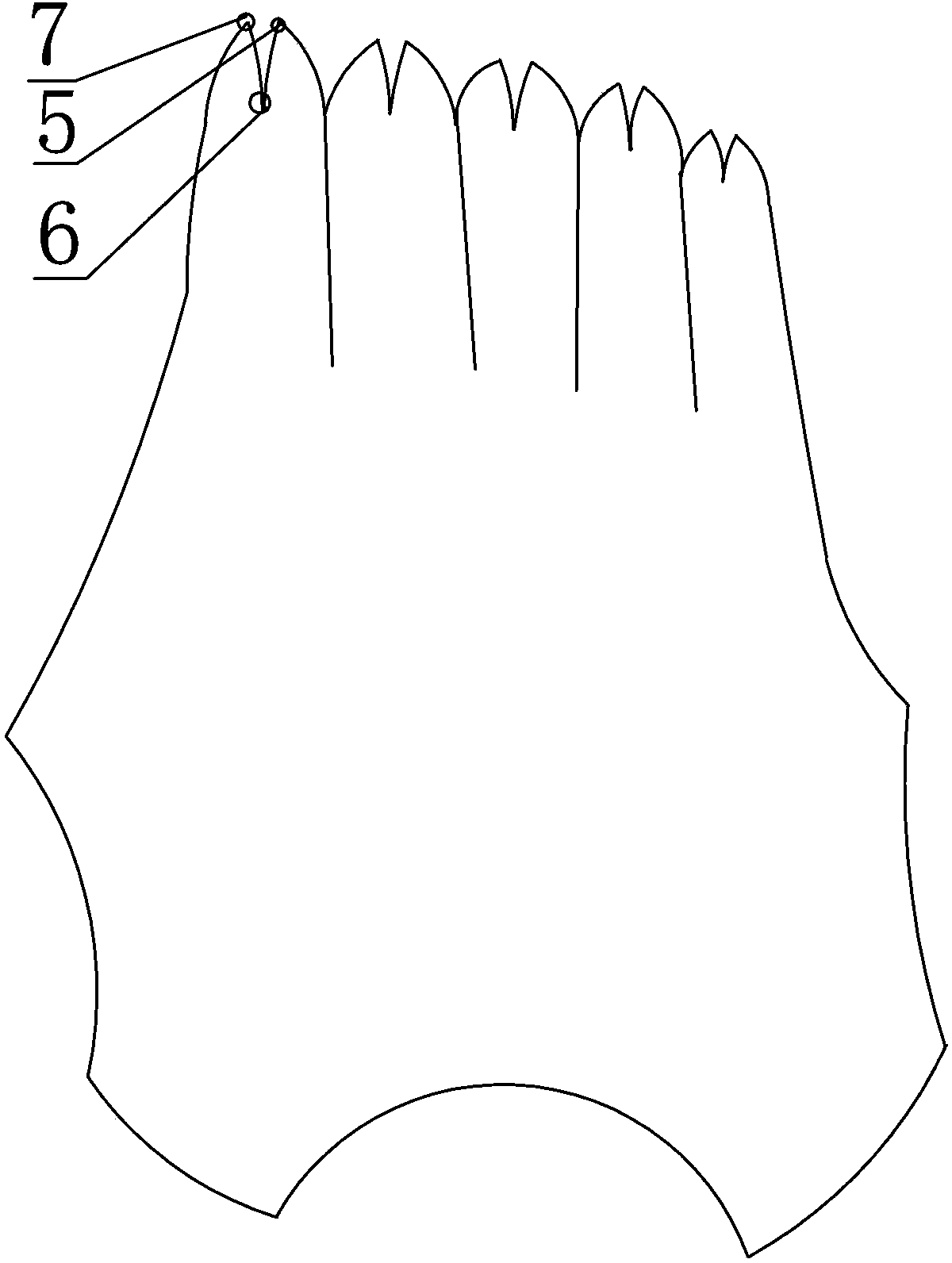

Five-toe shoe and making method thereof

Owner:东莞市福派仕织造有限公司

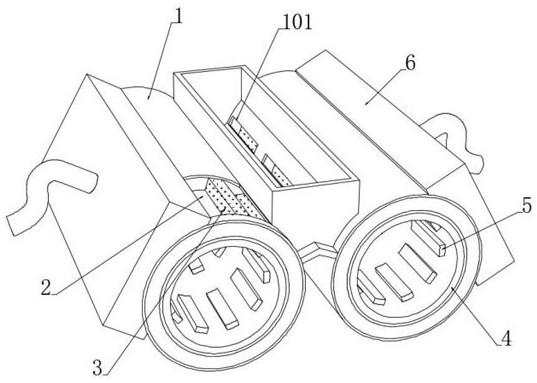

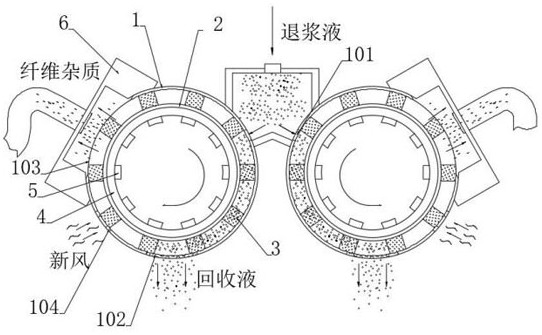

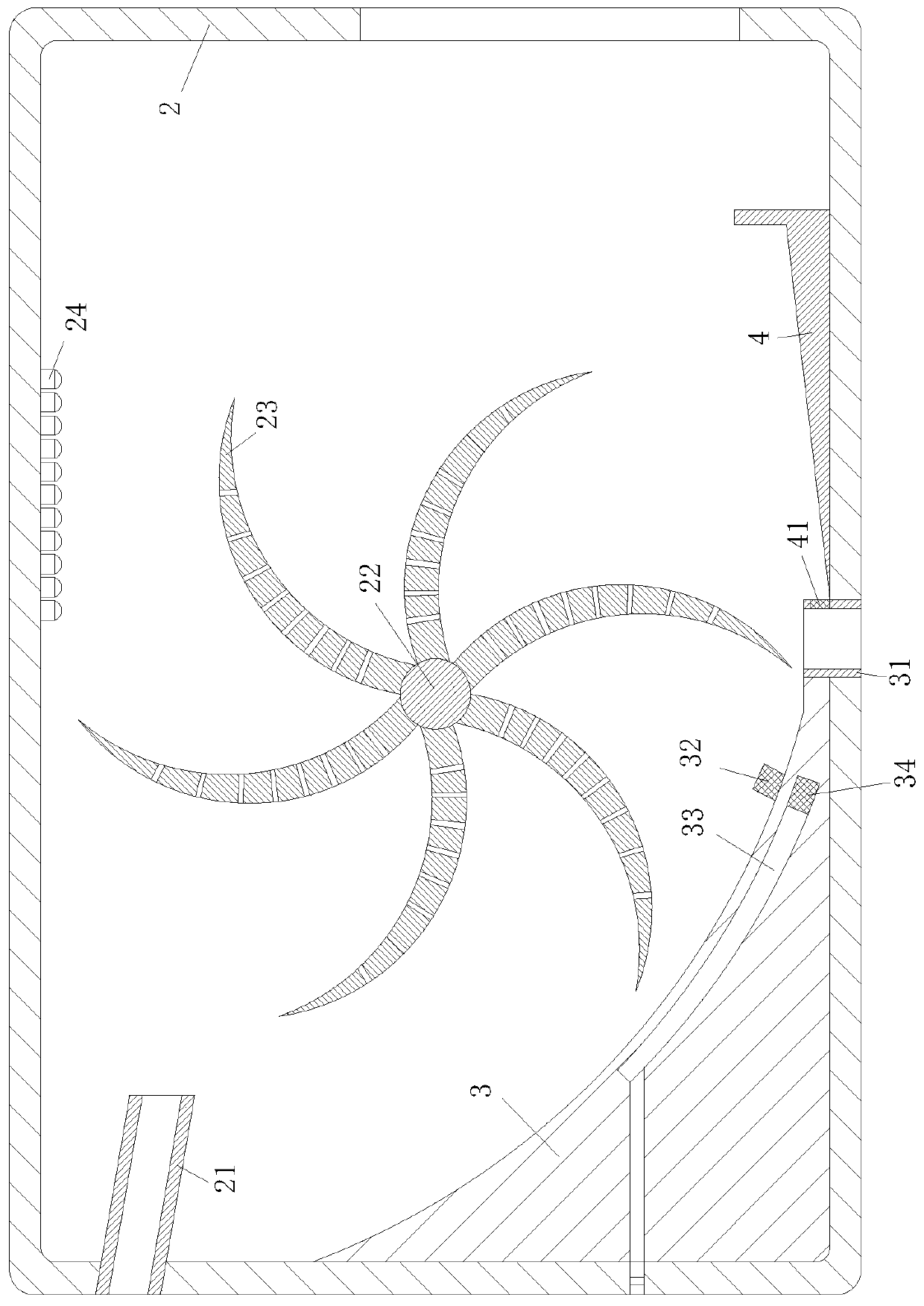

Textile sizing agent recycling process

InactiveCN113249909AOvercome stickinessEasy to catchTextile treatment machine arrangementsTextile treatment cleaning apparatusFiberTextile technology

Owner:南通隆彩纺织科技有限公司

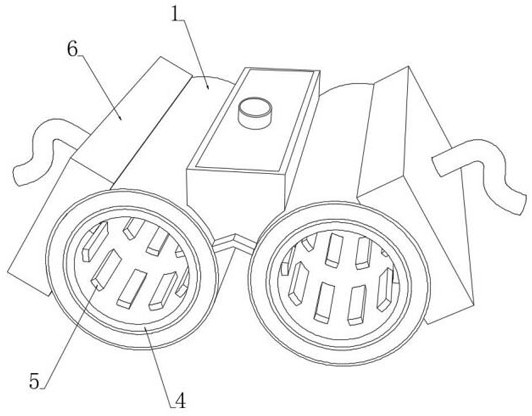

Drying device capable of preventing drying speed from being affected by excessive water in textiles

InactiveCN112984966AAvoid affecting drying speedEasy to squeeze water outDrying solid materials without heatDrying gas arrangementsTextile technologyWater storage tank

The invention relates to the technical field of textiles, and discloses a drying device capable of preventing the drying speed from being affected by excessive water in the textiles. The drying device comprises a fixing seat, a water storage tank is welded to the top of the fixing seat, and a water drain valve is welded to the left side of the water storage tank. According to the drying device capable of preventing the drying speed from being affected by the excessive water in the textiles, a cam rotates, at the moment, a pressing rod can drive a water pressing plate to periodically slide up and down in a drying chamber, and thus the effect of preventing the drying speed from being affected by the excessive water in the textiles is achieved. A rotating disc is rotated, and at the moment, the distance between the water pressing plate and a cross rod can be changed, so that the effect of conveniently extruding the textiles of different thicknesses to discharge the water from the textiles is achieved; air generated by rotation of fan blades moves to the bottom of the water pressing plate through a first air guide pipe, then flows back to the interior of a second sealing cavity through a second air guide pipe, and finally circulates after the water is filtered through a connecting pipe, so that the effects of improving the drying efficiency of the textiles and reducing resource waste are achieved.

Owner:邓清源

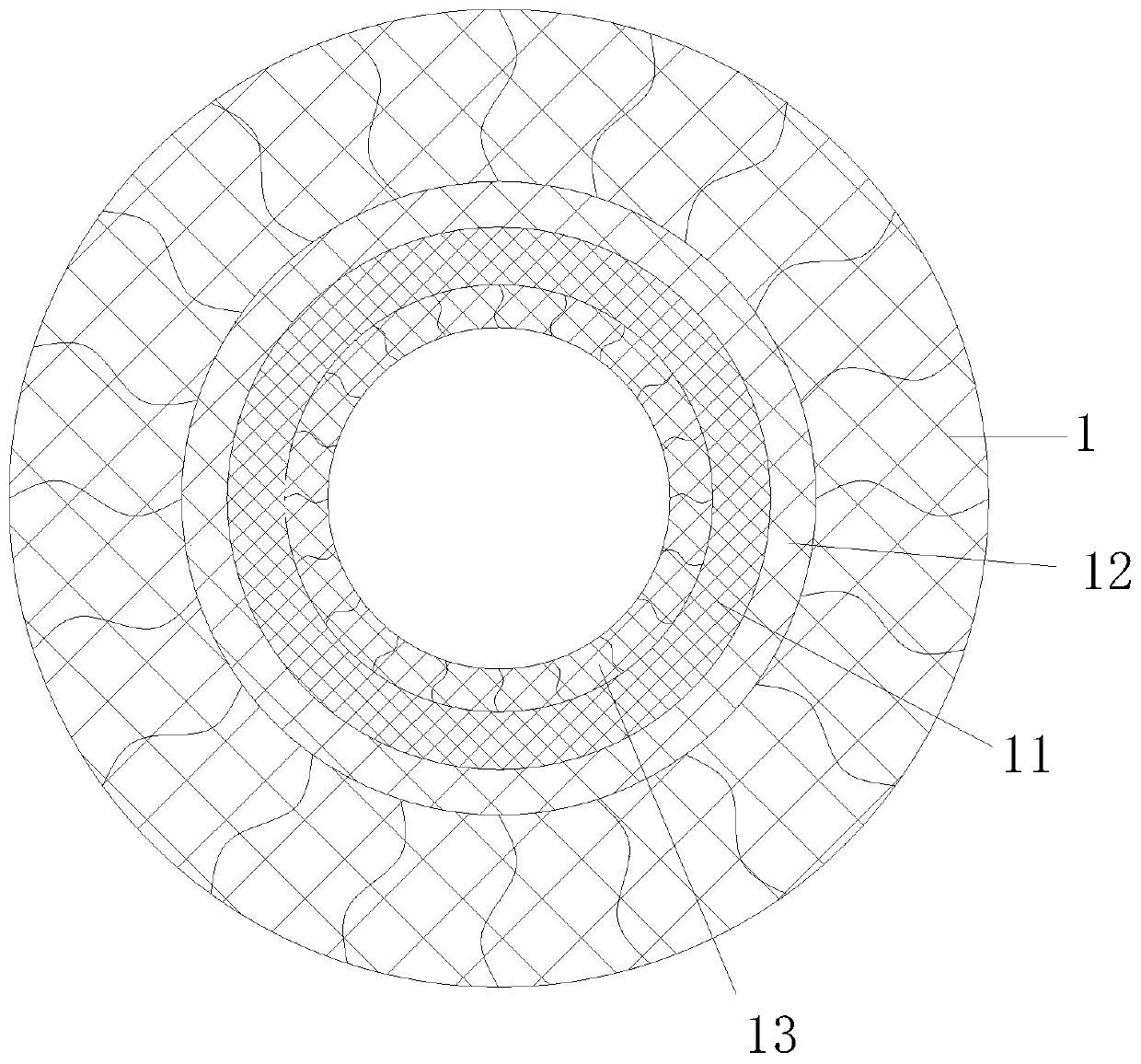

Antibacterial nanofiber

PendingCN111286811APrevent outflowAvoid pollutionHollow filament manufactureConjugated synthetic polymer artificial filamentsPolyesterTextile technology

Owner:王康辉

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap