Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Wire frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

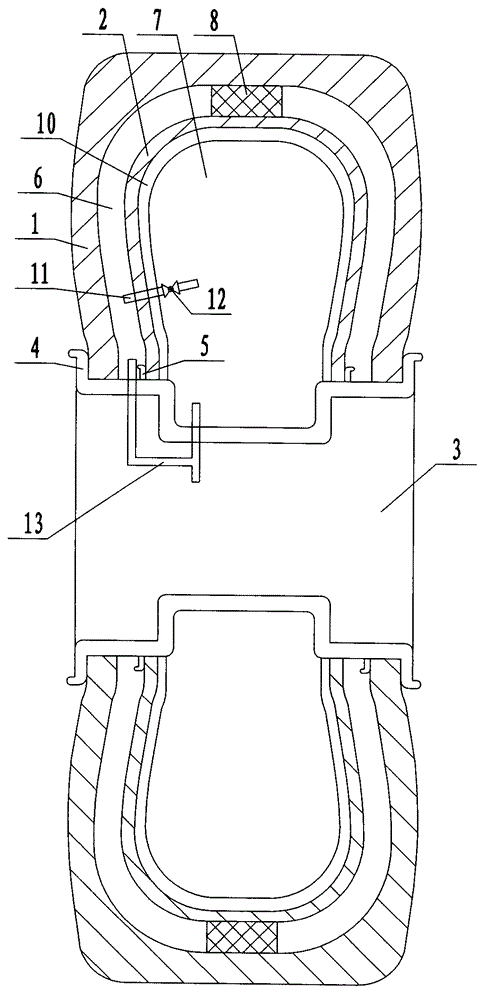

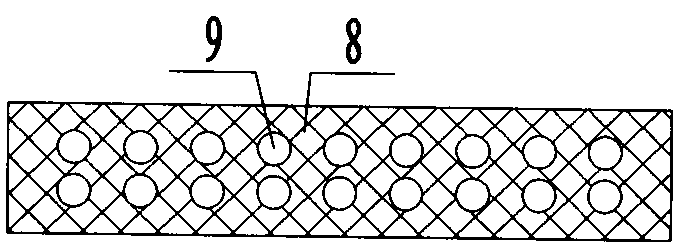

Blowout proof tire

InactiveCN104890452AAvoid loss of life and propertyImprove driving safetyTyre partsEngineeringCheck valve

Owner:卞婧

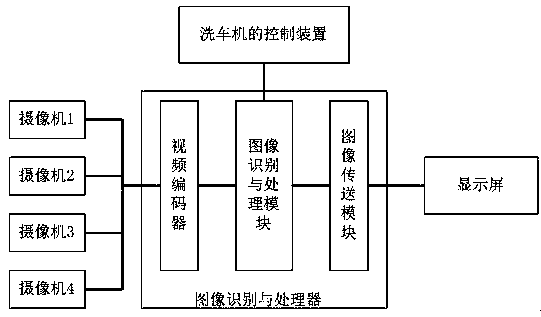

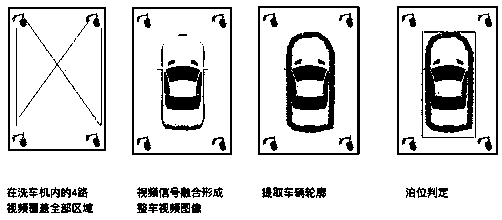

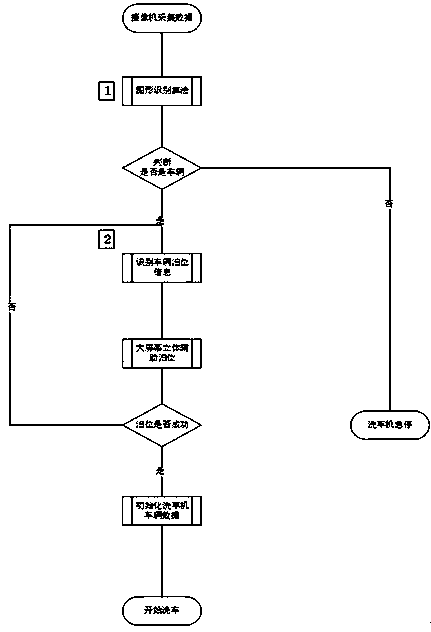

Car washer image parking system and method thereof

PendingCN110288795AVehicle cleaning apparatusClosed circuit television systemsWire frameParking space

Owner:上海讯华企业管理咨询中心

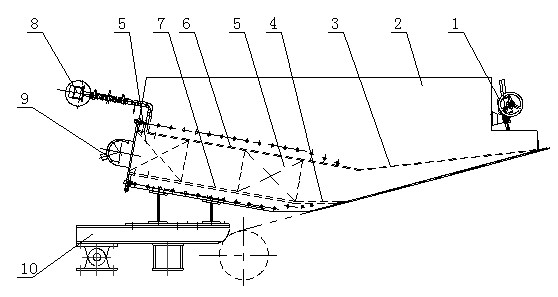

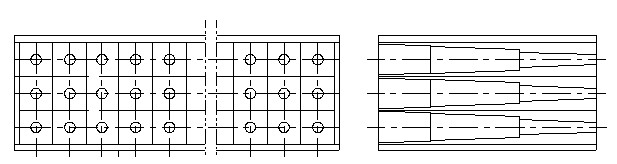

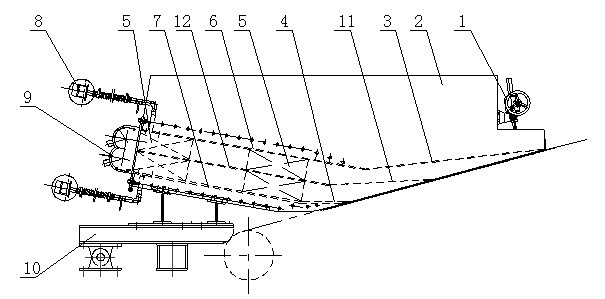

Hydrodynamic inclined-wire stock discharge box

Owner:SOUTH CHINA UNIV OF TECH

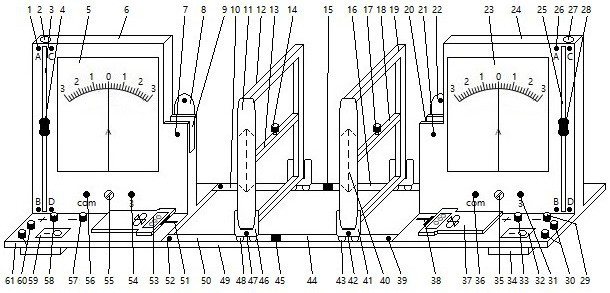

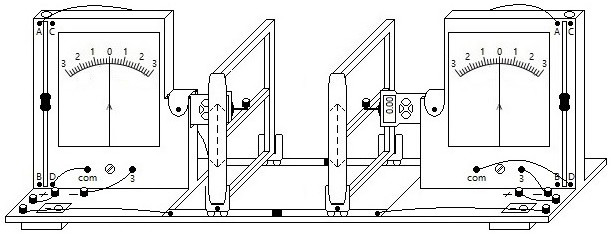

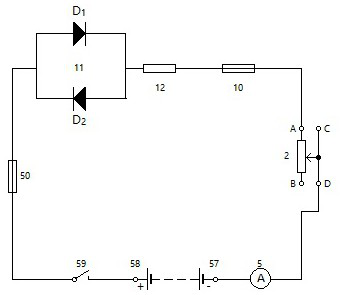

Electrified parallel wire frame interaction demonstration instrument

InactiveCN112396934AReduce frictionStable and free movementEducational modelsElectrical conductorElectrical battery

Owner:HUAIHUA UNIV

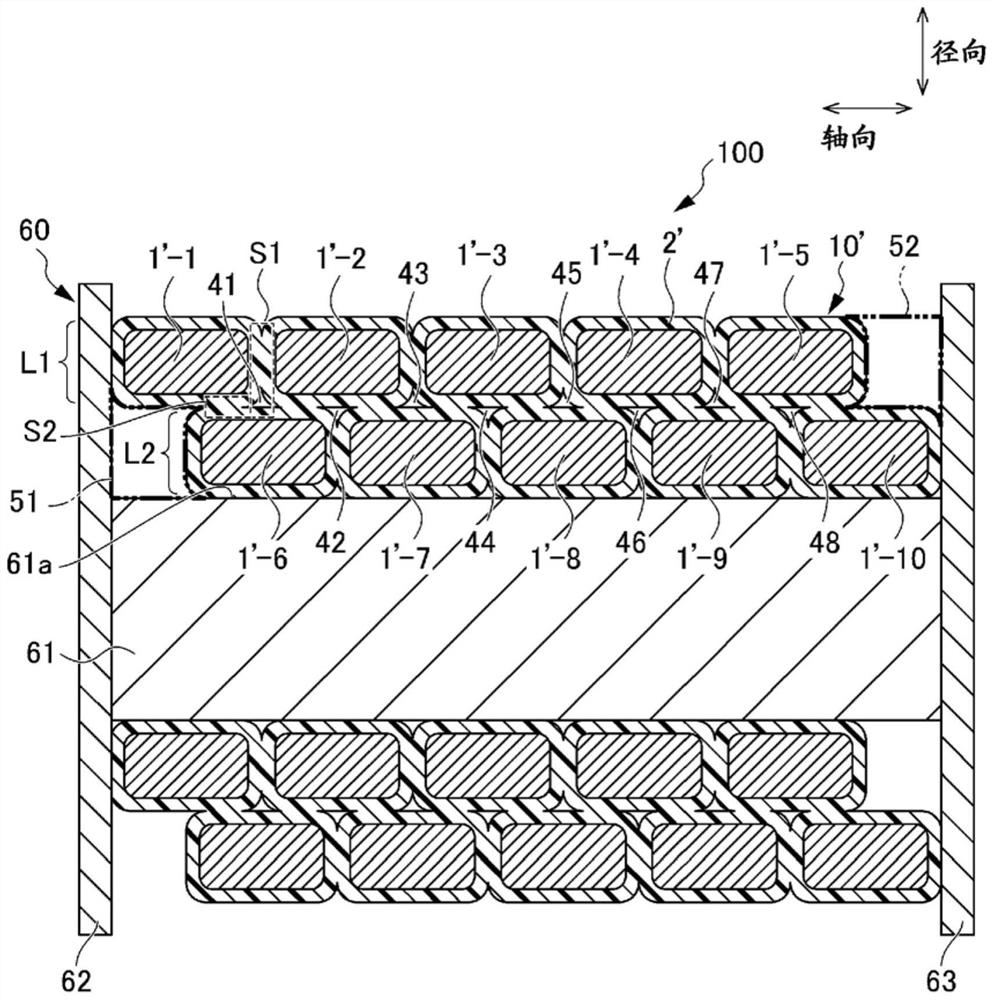

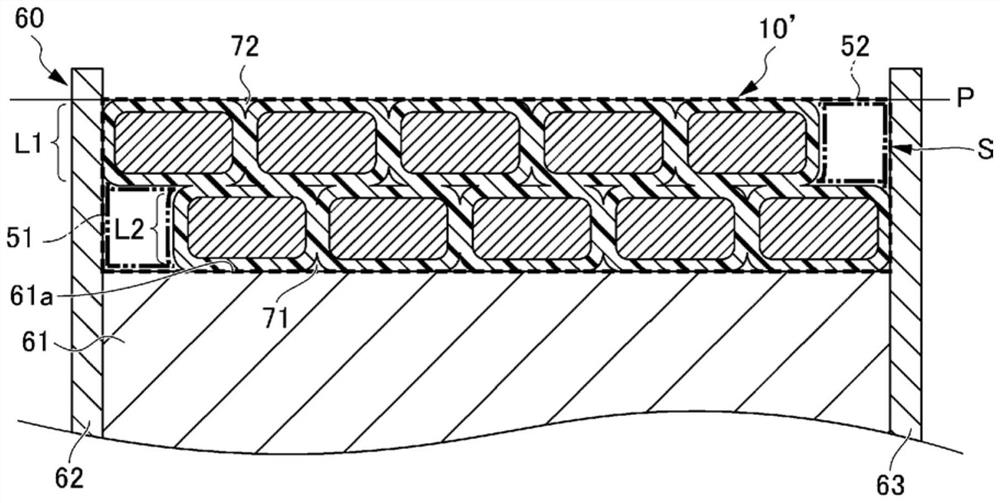

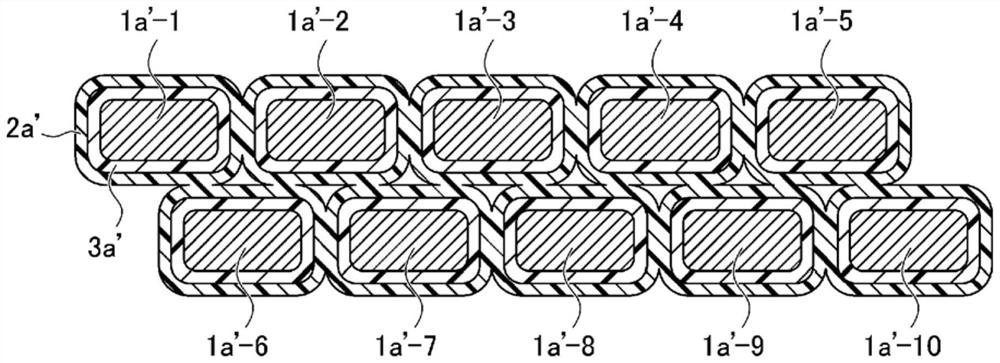

Superconducting coil, method for manufacturing same, and superconducting flat wire for superconducting coil

PendingCN114746964ASuperconductors/hyperconductorsInductances/transformers/magnets manufactureWire rodSuperconducting Coils

Owner:FURUKAWA ELECTRIC CO LTD

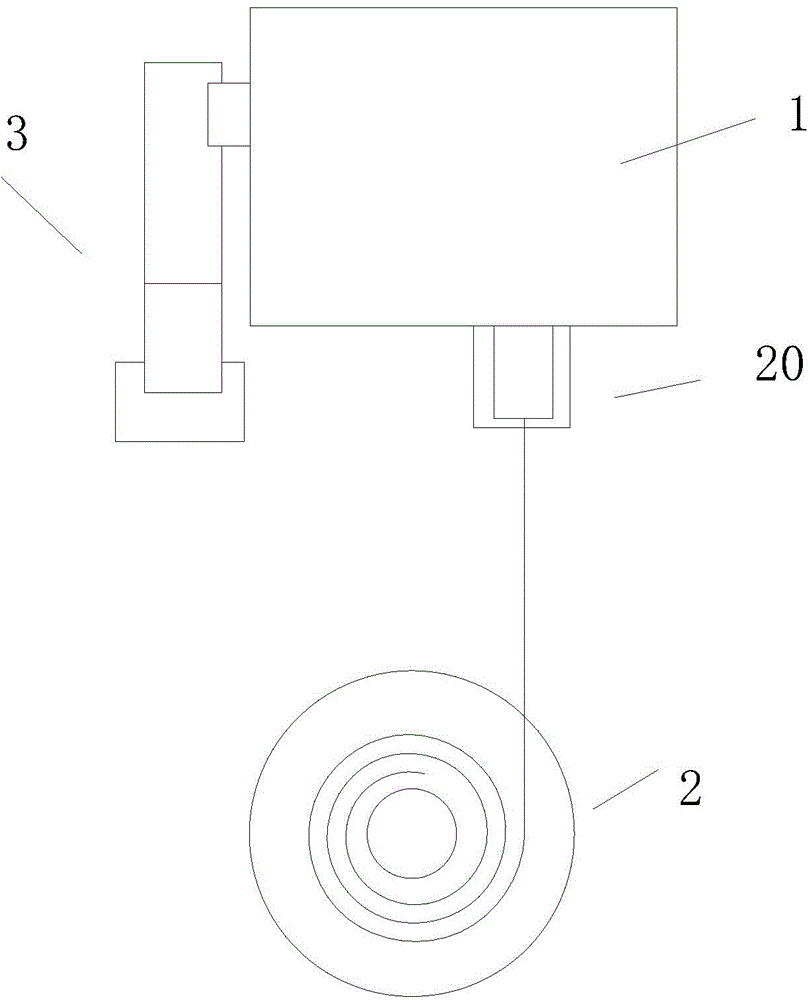

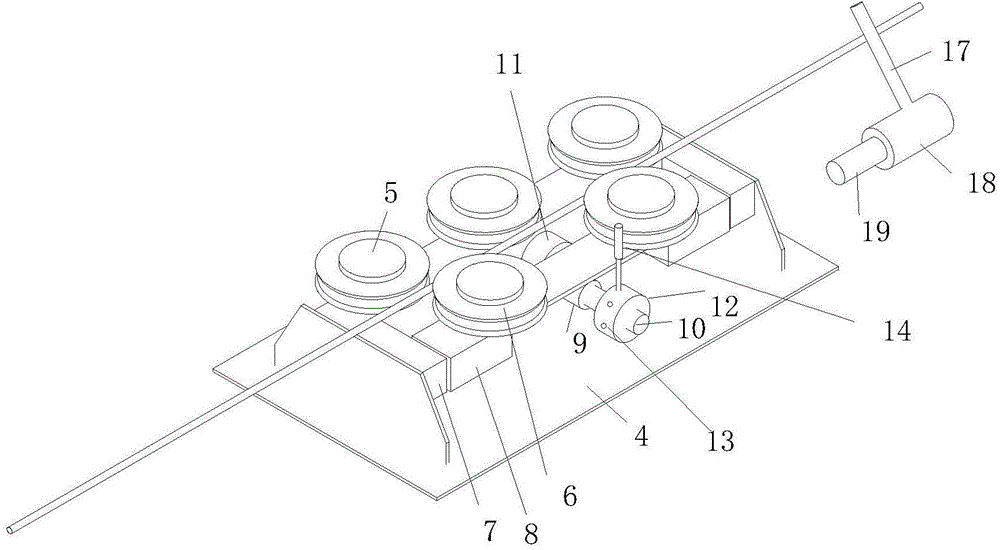

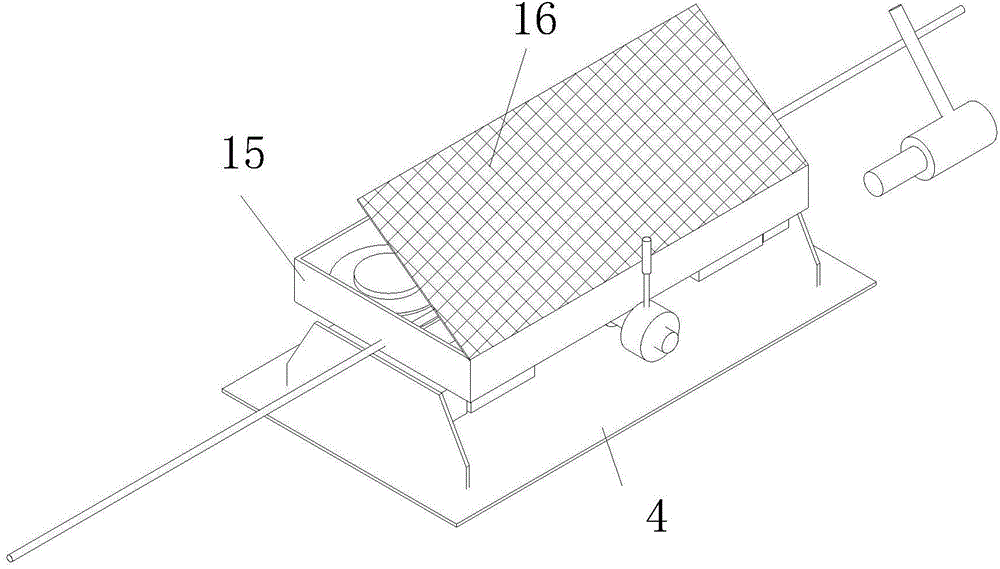

Feeding mechanism of automatic cold header for machining piston pins

The invention discloses a feeding mechanism of an automatic cold header for machining piston pins. The feeding mechanism comprises a main machine (1), a feeding mechanism body (20) is arranged on the front portion of the main machine (1), the feeding mechanism is connected with an iron wire frame (2) through an iron wire, and a discharging mechanism (3) is arranged on one side of the main machine (1). The feeding mechanism body comprises a base (4), fixed wheels (5) are arranged on one side of the base (4), and moving wheels (6) are arranged on the other side of the base (4). Side bases (7) are arranged on two sides of the base (4), sliding bases (8) are arranged on the inner sides of the side bases (7), and the contact surfaces of the sliding bases (8) and the side bases (7) are in sliding fit. The moving wheels (6) are arranged on the upper sides of the sliding bases (8), a threaded barrel (9) is fixed below the sliding bases (8), a threaded column (10) is arranged in the threaded barrel (9), a bearing pedestal (11) is arranged at one end of the threaded column (10), a rotating ring (12) is fixed to the other end of the threaded column (10), the rotating ring (12) is provided with a circle of small holes (13), and a rotating handle (14) is arranged in one small hole (13) in an embedded mode.

Owner:湖州锐狮标准件制造有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap