Feeding mechanism of automatic cold header for machining piston pins

A technology of feeding mechanism and cold heading machine, applied in the directions of pins, connecting components, mechanical equipment, etc., can solve the problems of unreasonable structure, high feeding failure rate and reducing efficiency, so as to reduce the feeding failure rate and improve the product. quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

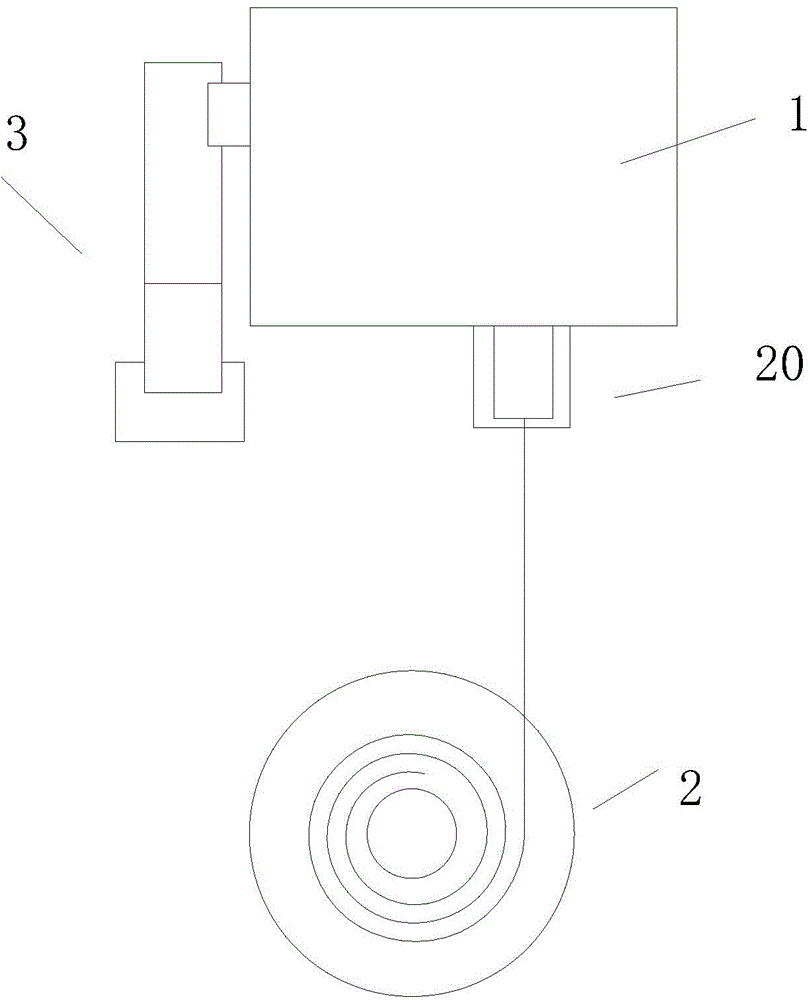

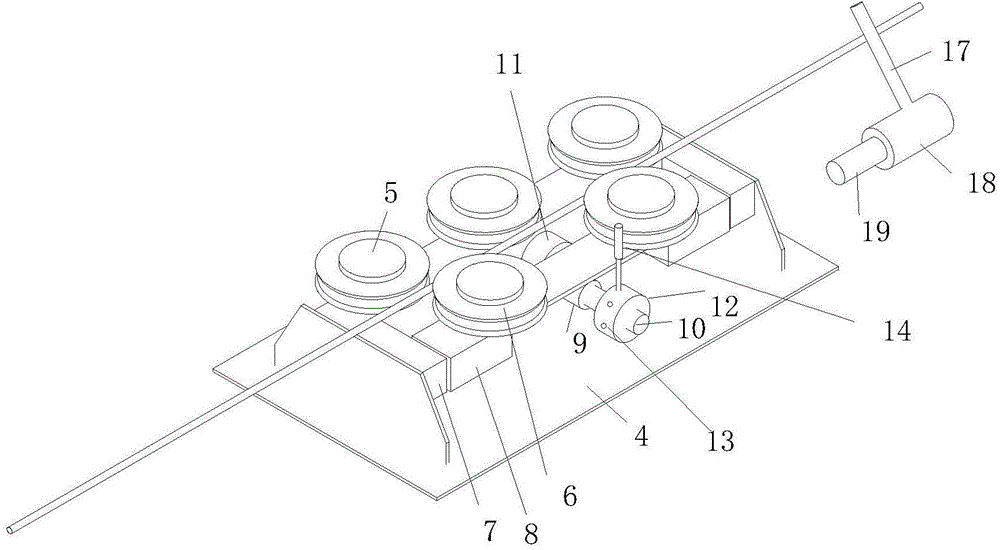

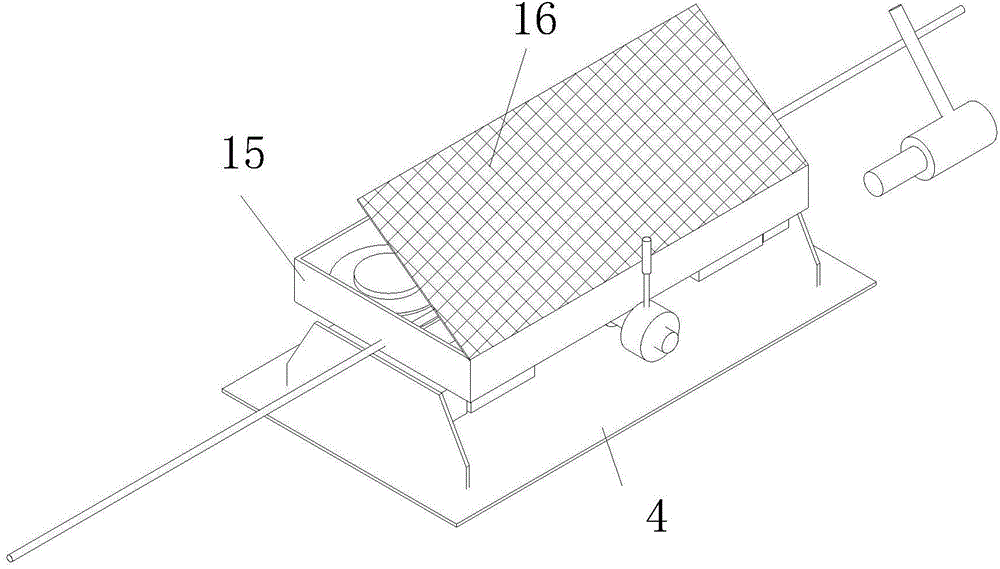

[0012] Embodiment: a kind of feeding mechanism of the automatic cold heading machine of processing piston pin, constitutes as figure 1 As shown, the main machine 1 including cold heading parts, the front part of the main machine 1 is provided with a feeding mechanism 20, the feeding mechanism is connected with a wire rack 2 wound with iron wire raw materials through iron wires, and the side of the main machine 1 is provided with a discharge mechanism 3 ; as attached figure 2 and 3 As shown, the feeding mechanism includes a base 4, one side of the base 4 is provided with two fixed wheels 5, and the other side of the base 4 is provided with 3 moving wheels 6; Seat 7, the side seat and the inside of the base are fixed, and the inside of the side seat 7 is provided with a slide seat 8, and the two sides of the slide seat 8 slide and cooperate with the contact surface of the side seat 7, such as slide rails and chute; above the slide seat 8 There is a moving wheel 6, through the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap