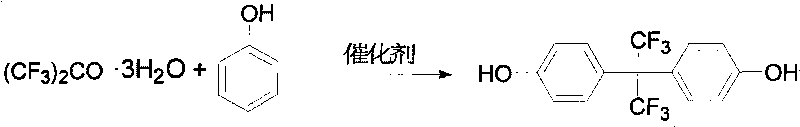

One-step preparation method of bisphenol AF

A bisphenol and phenol technology, applied in the field of bisphenol AF preparation, can solve the problems of difficult recycling and reuse, inconvenient production and operation, dangerous and cumbersome operation, etc., to achieve safe production, mild operating conditions and good reaction selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

[0021] Add 0.2mol phenol and 0.02mol HFA·3H to the three-neck flask successively 2 O, 0.02mol trifluoromethanesulfonic acid, N 2 Replace the air in the bottle with air and react at 90°C for 60 hours. After the reaction is over, add 10 mL of a mixture of xylene and ether, stir, wash with water three times, extract again, and combine the organic phases. The catalyst can be reused after water removal treatment. Organic phase NaHCO 3 Neutralized in aqueous solution, anhydrous Na 2 SO 4 After drying, the organic solvent and unreacted phenol are removed to obtain a crude product. The total yield of the reaction is 95%, and the selectivity of bisphenol AF is 82%.

Example Embodiment

[0022] Example 2

[0023] Add 0.04mol phenol and 0.02mol HFA·3H to the three-neck flask 2 O, 0.32mol methanesulfonic acid, N 2 Replace the air in the bottle with air, react at 170~180℃ for 15h. After the reaction, 10 mL of dichloromethane was added and stirred, washed with water three times, and then extracted, and the organic phases were combined. The catalyst can be reused after water removal treatment. Organic phase NaHCO 3 After the aqueous solution is neutralized and dried with anhydrous sodium sulfate, the organic solvent and unreacted phenol are removed to obtain a crude product. The total yield of the reaction was 89%, and the selectivity of bisphenol AF was 90%.

Example Embodiment

[0024] Example 3

[0025] Add 0.14mol phenol and 0.02mol HFA·3H to the three-neck flask successively 2 O, 0.56mol benzenesulfonic acid, N 2 Replace the air in the bottle with air, and reflux at 150~160℃ for 25h. After the reaction was cooled to room temperature, a small amount of dichloromethane was added and stirred, washed with water three times, and then extracted, and the organic phases were combined. Methanesulfonic acid can be obtained by removing water from the water phase, which can be reused. Organic phase NaHCO 3 After the aqueous solution is neutralized and dried with anhydrous sodium sulfate, the solvent and part of the unreacted phenol in the organic phase are removed to obtain a crude product. The total yield of the reaction is 94%, and the selectivity of bisphenol AF is 95%. Recrystallized to obtain pure bisphenol AF.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap