Method for growing and preparing aluminium borate whisker/ aluminium composite powder on aluminium powder surface in situ

An in-situ growth technology for aluminum borate whiskers, which is applied in the field of ceramic whiskers/metal composite powder materials, can solve the problem of high temperature for preparing aluminum borate whiskers, and achieves good continuity and bonding, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

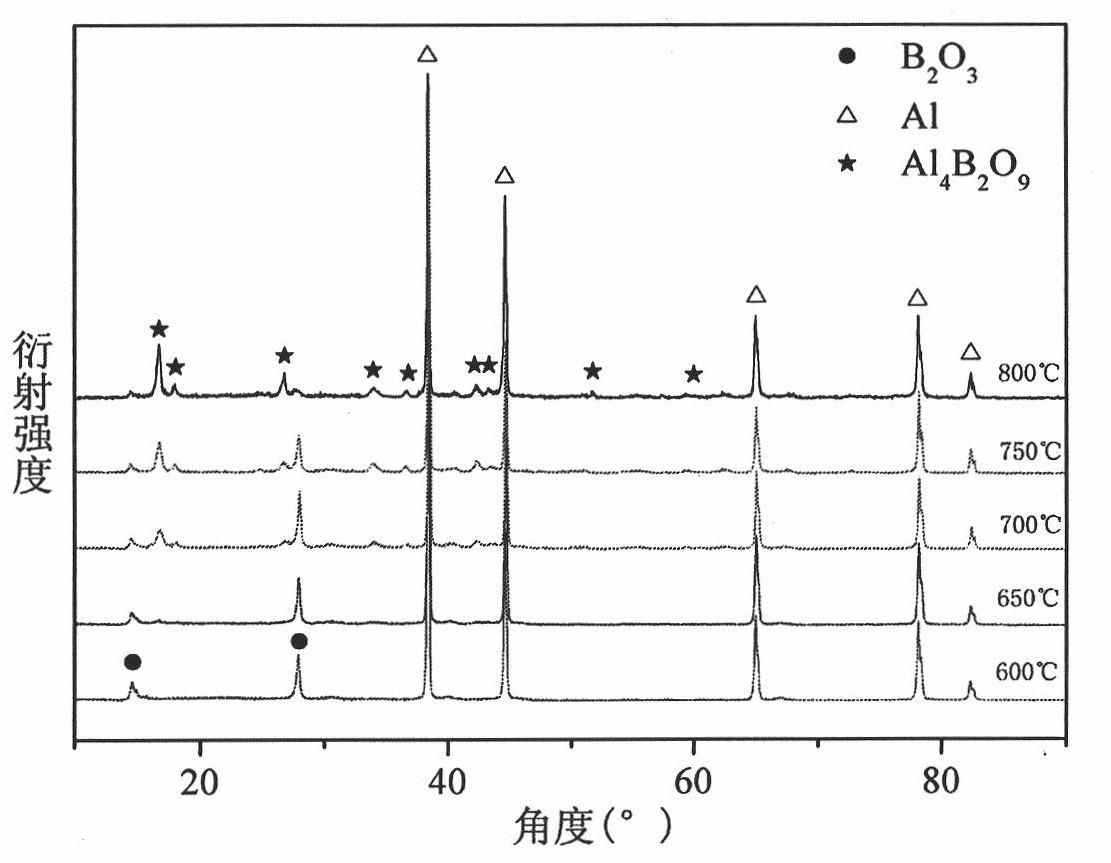

Image

Examples

Embodiment 1

[0015] After weighing 15g of aluminum powder and 1g of boric acid powder and mixing them, the powder and 110g of zirconia balls were added to a 400mL capacity stainless steel ball mill tank, and the prefabricated Mix the powder evenly. Spread the prefabricated mixed powder in the alumina ark, and place the alumina ark in the constant temperature zone in the middle of the quartz heating furnace. The temperature was raised to 650°C for calcination, kept at constant temperature for 2 hours to grow whiskers, and the furnace temperature was naturally lowered to room temperature under the protection of argon, and the product was aluminum borate whiskers / aluminum composite powder.

Embodiment 2

[0017] After weighing 14g of aluminum powder and 1g of boric acid powder and mixing them, the powder and 160g of zirconia balls were added to a 400mL capacity stainless steel ball mill jar, and the prefabricated Mix the powder evenly. Spread the prefabricated mixed powder in the alumina ark, and place the alumina ark in the constant temperature zone in the middle of the quartz heating furnace. Calcined at 700°C, kept at constant temperature for 1.5 hours to grow whiskers, and then the furnace temperature was naturally lowered to room temperature under the protection of argon, and the product was aluminum borate whiskers / aluminum composite powder.

Embodiment 3

[0019] After weighing 12g of aluminum powder and 1g of boric acid powder and mixing them, the powder and 165g of zirconia balls were added to a 400mL capacity stainless steel ball mill tank, and the prefabricated Mix the powder evenly. Spread the prefabricated mixed powder in the alumina ark, and place the alumina ark in the constant temperature zone in the middle of the quartz heating furnace. Calcined at 750°C, kept at constant temperature for 1 hour to grow whiskers, and then the furnace temperature was naturally lowered to room temperature under the protection of argon, and the product was aluminum borate whiskers / aluminum composite powder.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap