Preparation method of surface localized surface plasmon resonance (LSPR)-based molecular imprinting bionic olfaction Ag nano wire sensor

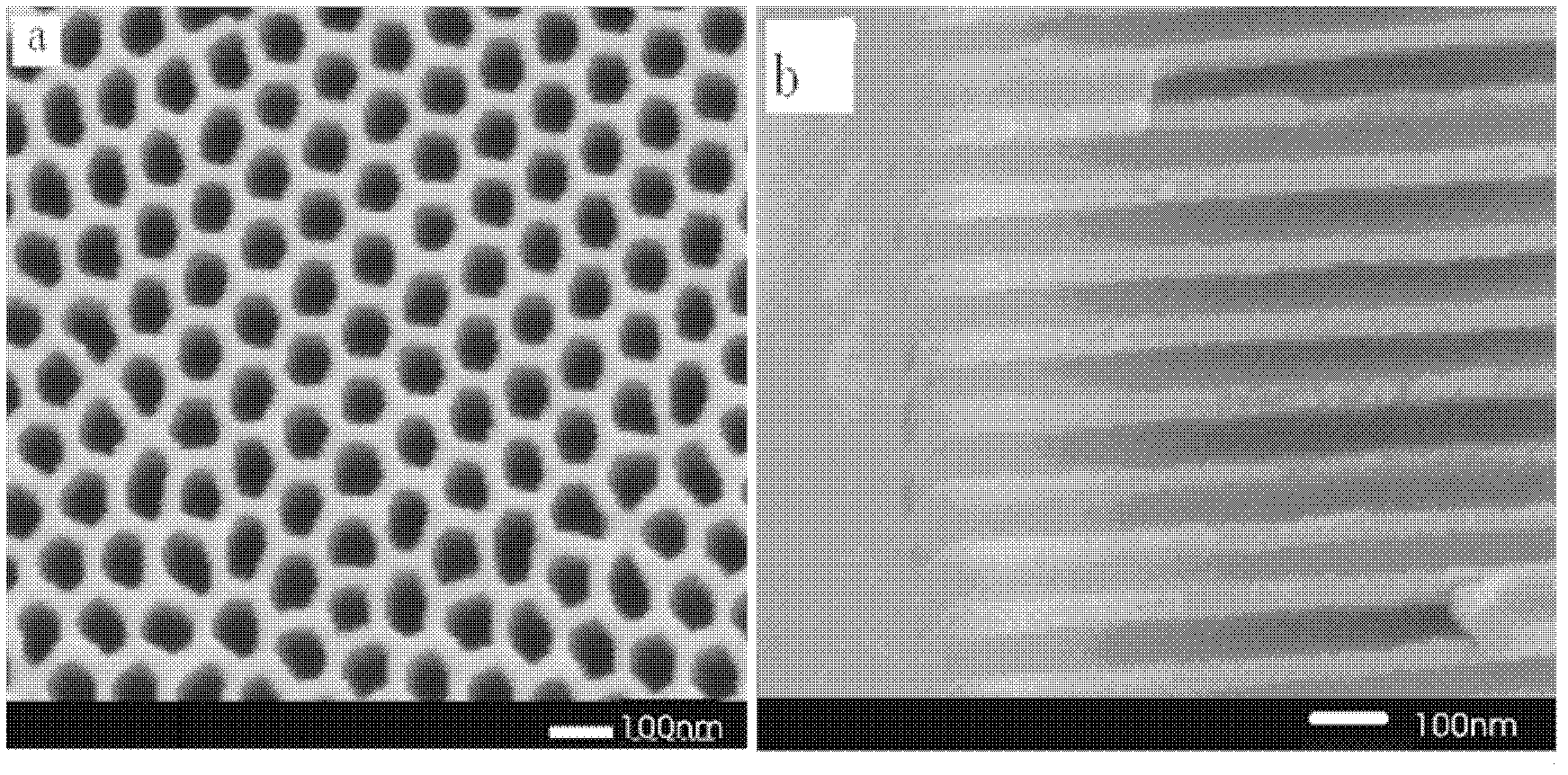

A molecular imprinting and nanowire technology, applied in the field of sensors, can solve the problems of difficult detection of dioxin-like substances and difficult dioxin detection technology, so as to enhance the molecular recognition effect of LSPR, improve the detection efficiency and sensitivity, and improve the detection efficiency. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

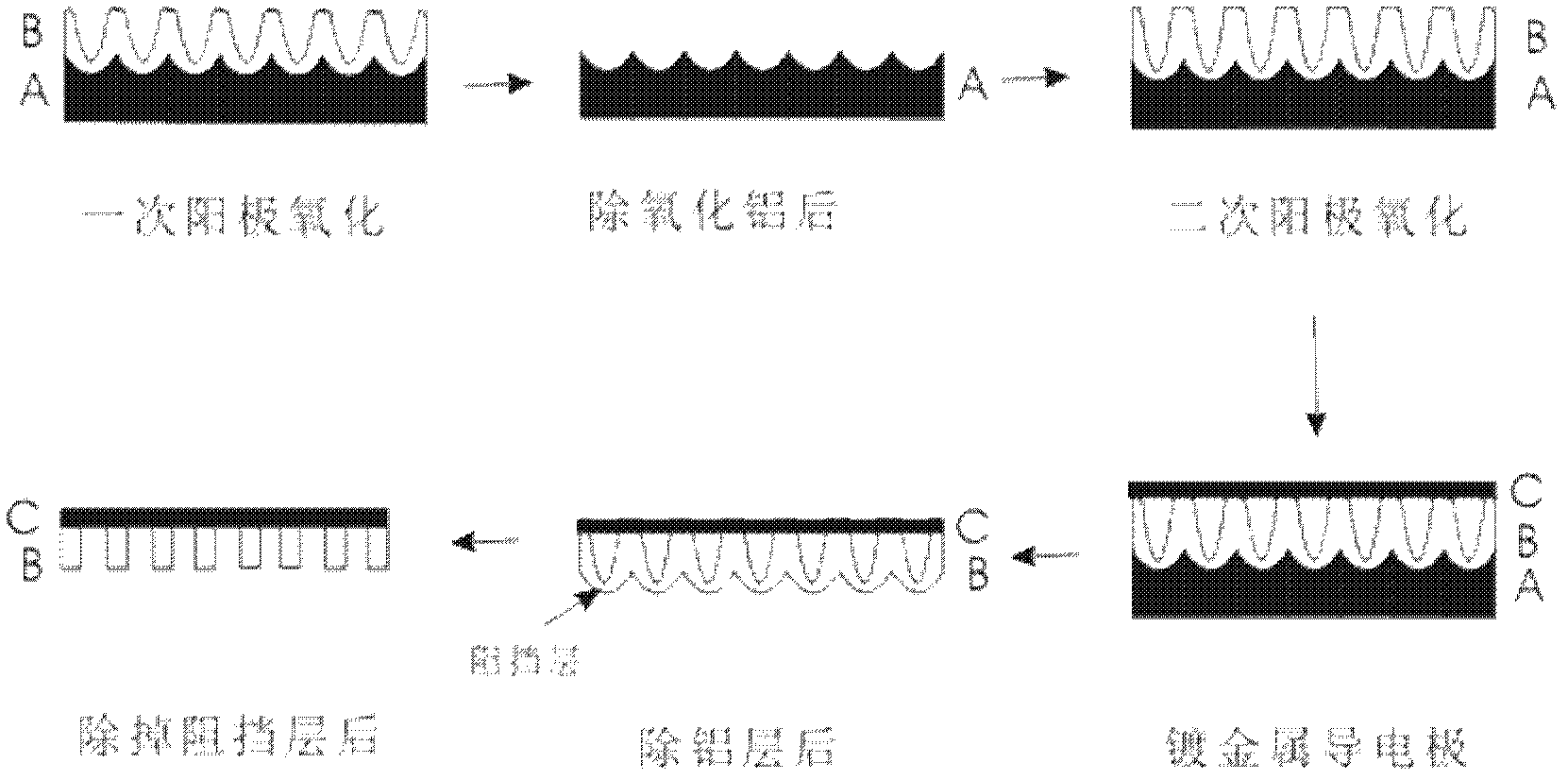

[0025] A method for preparing a molecularly imprinted bionic olfactory Ag nanowire sensor based on surface LSPR, comprising the steps of:

[0026] 1) Pretreatment of aluminum flakes: first soak high-purity aluminum flakes with a thickness of 0.2-0.3mm and a mass purity ≥ 99.99% in acetone for 30 minutes to remove surface oil stains, and then immerse them in 0.1mol / L NaOH solution respectively and 0.1mol / L HCl solution for 20 minutes to dissolve the oxide layer on the surface and polish it; then dry it, put it in a vacuum furnace, and anneal it at 400°C for 4 hours. The purpose of annealing is to eliminate the mechanical stress inside the aluminum sheet and reduce the crystal defects in the lattice, increase the grain size or even eliminate the grain boundary, thereby improving the ordering degree of the template;

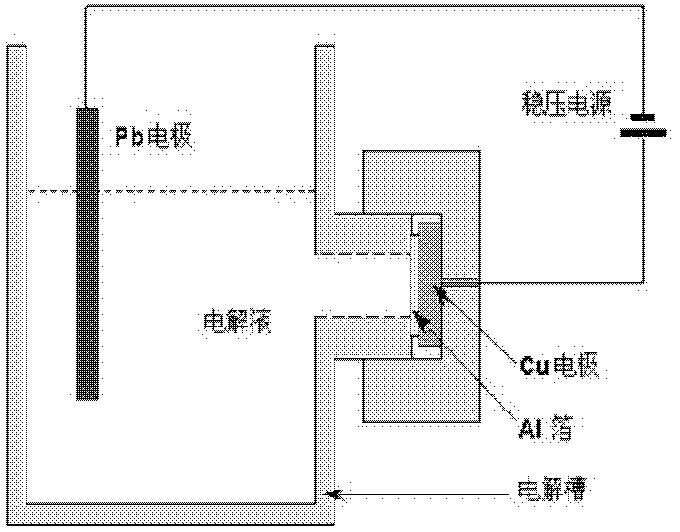

[0027] 2) Primary anodizing: the pre-treated aluminum sheet (the aluminum sheet is used as the anode, and the cathode can be a lead plate) is placed in an H-shaped

Embodiment 2

[0038] A method for preparing a molecularly imprinted bionic olfactory Ag nanowire sensor based on surface LSPR, comprising the steps of:

[0039] 1) Pretreatment of aluminum flakes: first soak high-purity aluminum flakes with a thickness of 0.2-0.3mm and a mass purity ≥ 99.99% in acetone for 30 minutes to remove surface oil stains, and then immerse them in 0.1mol / L NaOH solution respectively and 0.1mol / L HCl solution for 20 minutes to dissolve the oxide layer on the surface and polish it; then dry it, put it in a vacuum furnace, and anneal it at 400°C for 4 hours. The purpose of annealing is to eliminate the mechanical stress inside the aluminum sheet and reduce the crystal defects in the lattice, increase the grain size or even eliminate the grain boundary, thereby improving the ordering degree of the template;

[0040] 2) Primary anodizing: the pre-treated aluminum sheet (the aluminum sheet is used as the anode, and the cathode can be a lead plate) is placed in an H-shaped

Embodiment 3

[0049] A method for preparing a molecularly imprinted bionic olfactory Ag nanowire sensor based on surface LSPR, comprising the steps of:

[0050] 1) Pretreatment of aluminum flakes: first soak high-purity aluminum flakes with a thickness of 0.2-0.3mm and a mass purity ≥ 99.99% in acetone for 30 minutes to remove surface oil stains, and then immerse them in 0.1mol / L NaOH solution respectively and 0.1mol / L HCl solution for 20 minutes to dissolve the oxide layer on the surface and polish it; then dry it, put it in a vacuum furnace, and anneal it at 400°C for 4 hours. The purpose of annealing is to eliminate the mechanical stress inside the aluminum sheet and reduce the crystal defects in the lattice, increase the grain size or even eliminate the grain boundary, thereby improving the ordering degree of the template;

[0051] 2) Primary anodizing: the pre-treated aluminum sheet (the aluminum sheet is used as the anode, and the cathode can be a lead plate) is placed in an H-shaped

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap