Vehicle automobile exhaust catalyst containing Ce-Zr-Fe-Mn composite oxide and preparation method thereof

A ce-zr-fe-mn and composite oxide technology, which is applied in the field of vehicle exhaust catalyst and its preparation, can solve the problems of low toxicity, high toxicity, high price of precious metals, etc., and achieves simple equipment, high safety, The effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Example 1 Ce-Zr-Fe-Mn composite oxide, γ-Al 2 o 3 Synthesis with Pd / Fe-Al-Cr alloy:

[0015] Ce-Zr-Fe-Mn composite oxide and γ-Al 2 o 3 According to the mass ratio of 2:3, add 40% deionized water according to the total amount of the mixture, add it into the ball mill tank, and ball mill for 4 hours to make a slurry. Immerse the cordierite honeycomb ceramic carrier in the slurry, take it out after 2 minutes, dry it in the air, and bake it at 115°C for 4 hours. Immerse the dried carrier into PdCl containing Pd2.5g / L 2 Ammonia solution, stirred for 4h. Take it out, dry it in the air, and bake it at a certain temperature for 4 hours. Dip the dried carrier into KBH 4 solution, reacted for 30 minutes, washed with deionized water, and then carried out electroless plating at room temperature, reacted for 30 minutes and washed with deionized water until neutral, and dried at 115 ° C to obtain Ce-Zr-Fe-Mn composite oxide, γ- Al 2 o 3 And Pd / Fe-Al-Cr alloy.

example 2

[0016] Example 2 Catalyst to the catalytic activity investigation of automobile exhaust:

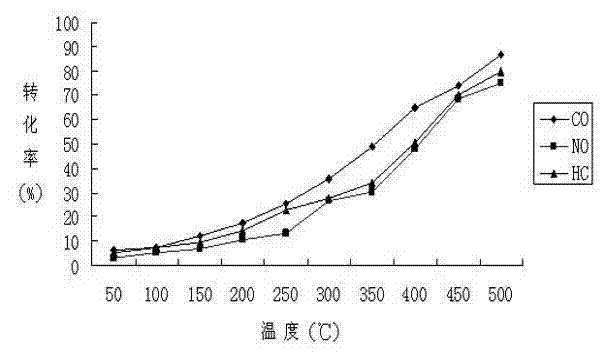

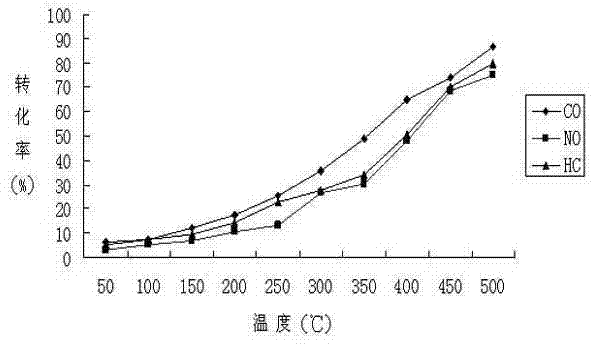

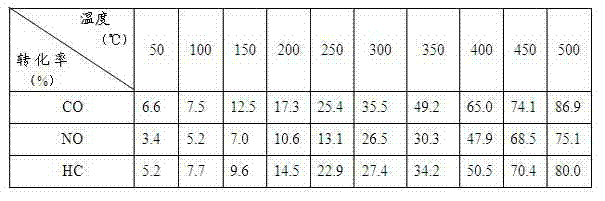

[0017] Use the prepared catalyst of example 1 to NO in automobile exhaust X , CO and HC conversion rates were investigated. The test is carried out in a high temperature reaction furnace. Will contain NO, CO 2 、H 2 The mixed gas is fed into the high-temperature reaction furnace, and the temperature is raised by 10°C every minute, and finally rises to 500°C. The experimental results are shown in Table 1 and figure 1 .

[0018] Table 1

[0019]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap