Turbine residual heat recycling and utilizing system

A technology of waste heat recovery and turbine, applied in pipeline system, engine components, machines/engines, etc., can solve the problems of increasing the risk of boiler safe operation, lack of spare boilers, reducing the chance of maintenance of heat medium boilers, etc., to reduce boiler fuel Consumption, improve equipment safety operation coefficient, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

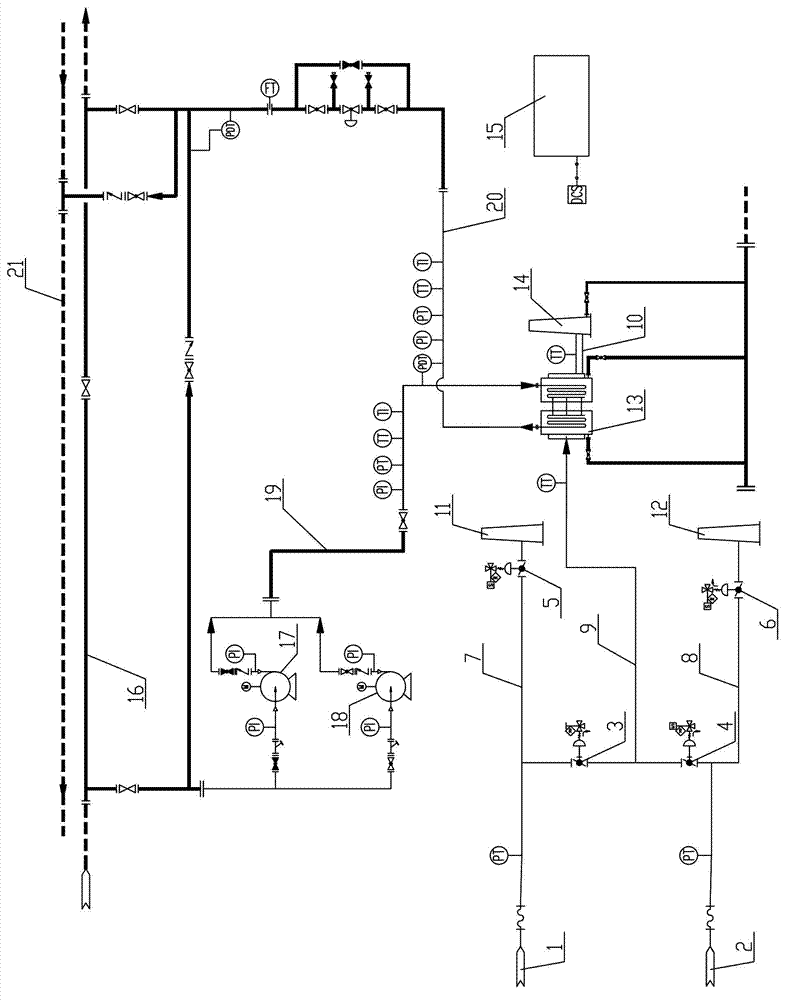

[0032] In order to further understand the content, features and effects of the present invention, the following describes the turbine waste heat recovery system of the present invention in detail:

[0033] As shown in the figure, this embodiment discloses a turbine waste heat recovery and utilization system, which uses the high-temperature flue gas discharged from the turbine as the heat source, recovers the flue gas waste heat, and uses the high-temperature flue gas to heat the waste heat furnace 13 The heat transfer oil in the heat exchange coil is heated to maximize the recovery and utilization of the waste heat of the turbine unit and realize energy saving and emission reduction. It is mainly composed of waste heat furnace 13, hot oil circulation pump, flue gas valve and on-site control panel 15, etc. Equipment composition.

[0034] The heat load of the waste heat furnace 13 in this embodiment is 3000KW, the design pressure is 1.2MPa, the maximum working pressure is 0.9MPa, the de

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap