Radiator for dryer in washing machine

A technology for dryers and washing machines, applied in household dryers, applications, washing devices, etc., can solve problems such as the influence of the life of the washing machine, heat instability, washing machine failures, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

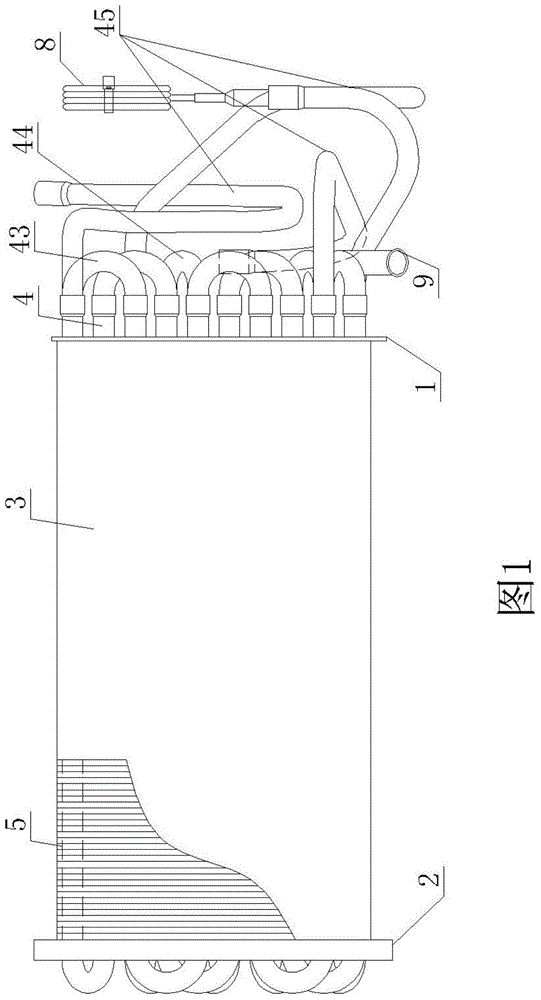

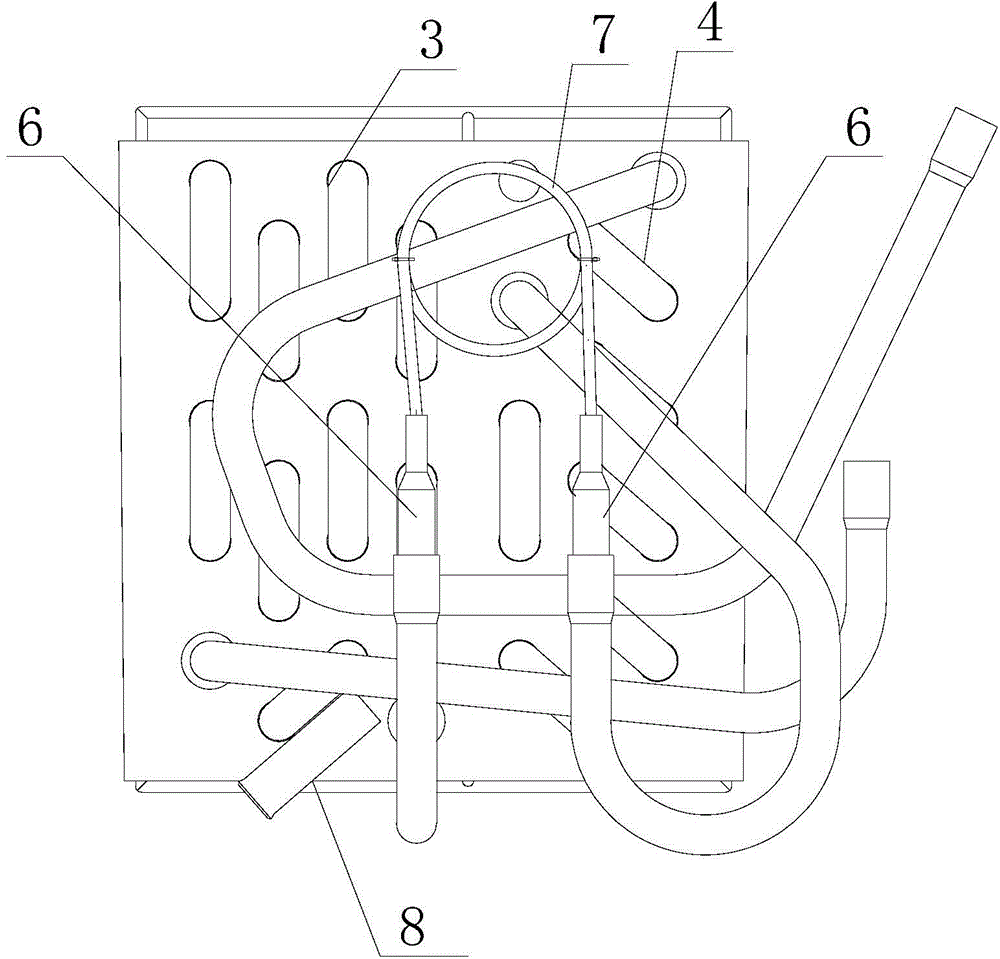

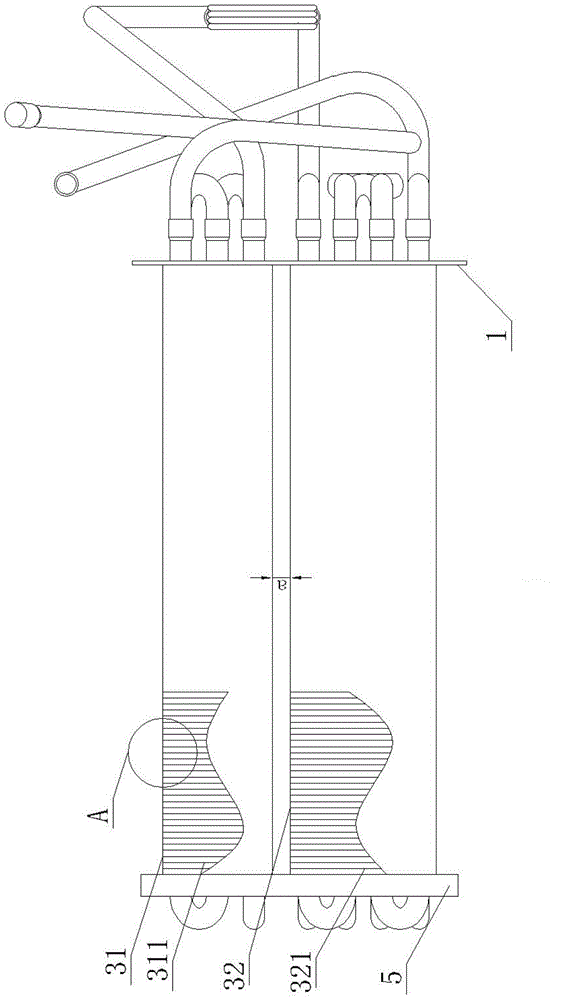

[0028] Such as Figure 1 to Figure 11 , a radiator for a washing machine inner dryer, comprising an upper seat 1, a base 2, a heat dissipation pipe 4, the heat dissipation pipe 4 adopts an internally threaded copper tube, and a fin group 3 arranged between the upper seat 1 and the base 2, the upper seat 1. The fin group 3 and the base 2 are connected through the heat dissipation pipe 4. The fin group 3 is evenly distributed with a plurality of sleeve holes 5 for the insertion of the heat dissipation pipe 4. The heat dissipation pipe 4 located outside the upper seat 1 is provided with a transformer. The diameter end 6 and the variable diameter end 6 are connected with a capillary tube 7 in a circular disc-shaped structure, and the heat dissipation pipe 4 is also connected with a temperature-sensing sleeve 8, and the upper seat 1 is provided with a

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap