Chemical method for preparing dye-sensitized solar cell slurry

A technology for solar cells and dye sensitization, applied in the field of preparation of dye-sensitized solar cell paste, can solve the problems of low output of P25 type titanium dioxide, complicated process of terpineol-based paste, easy introduction of impurities, etc. Large-scale industrial production, the realization of large-scale industrial production, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

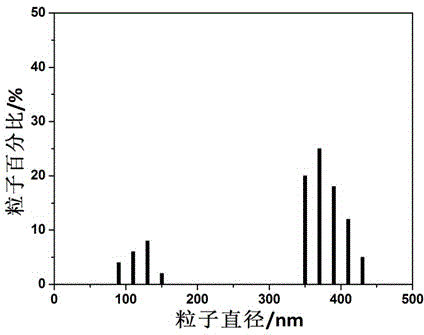

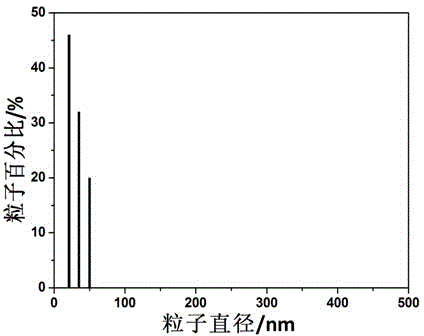

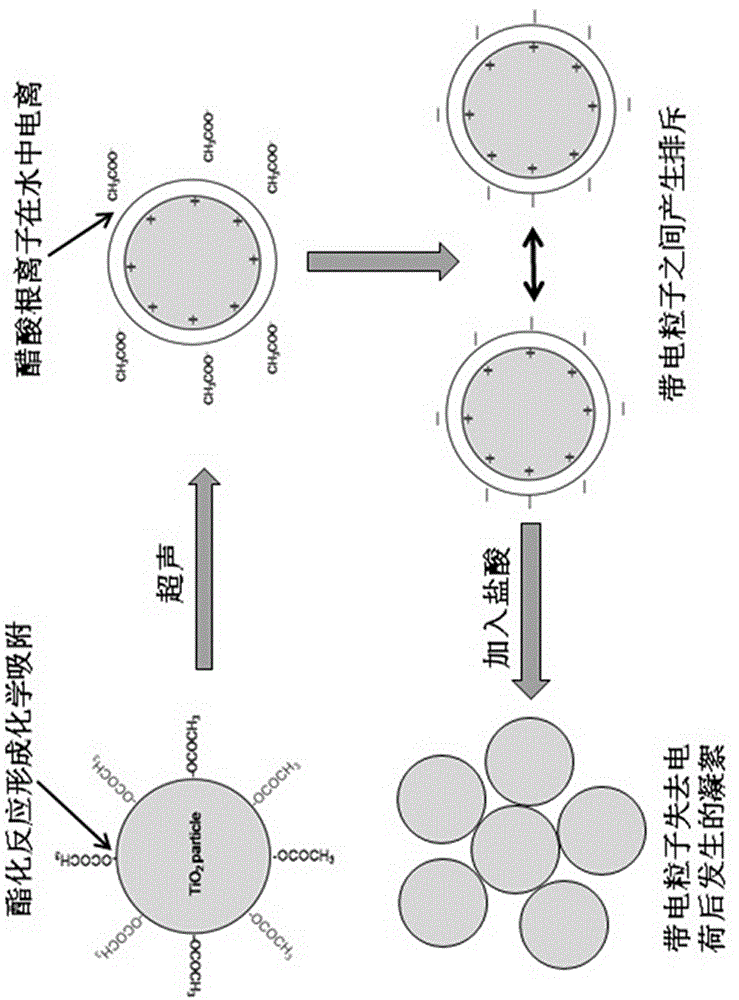

[0019] Specific implementation mode 1: In this implementation mode, dye-sensitized solar cell slurry is prepared according to the following steps:

[0020] 1. Weigh 10g of P25 powder, disperse it into 40ml of deionized water, add 2.5ml of glacial acetic acid (analytical purity 99.5 wt.%), and stir evenly;

[0021] 2. After sealing the mixed solution with plastic wrap, put it in a constant temperature box to raise the temperature to 90°C and keep it warm for 12 hours;

[0022] 3. Put the reacted mixed solution into a drying oven and dry at a constant temperature of 60°C;

[0023] 4. Weigh 0.5g of the modified powder, disperse it into 0.6ml of deionized water, and ultrasonicate for 5min;

[0024] 5. Slowly add 2ml of alcohol solution containing 0.1wt.% hydrochloric acid to make the titanium dioxide colloid into a viscous colloid;

[0025] 6. Use the screen printing method to coat a layer of slurry on the cleaned conductive glass, tear off the tape after natural drying, put it in

specific Embodiment approach 2

[0032] Specific implementation mode 2: In this implementation mode, dye-sensitized solar cell slurry is prepared according to the following steps:

[0033] 1. Weigh 10g of P25 powder, disperse it into 40ml of ethanol (analytical pure), add 2.5ml of glacial acetic acid (analytical pure 99.5 wt.%), and stir evenly;

[0034] 2. After sealing the mixed solution with plastic wrap, put it in a constant temperature box to raise the temperature to 80°C and keep it warm for 12 hours;

[0035] 3. Put the reacted mixed solution into a drying oven and dry at a constant temperature of 60°C;

[0036] 4. Weigh 0.5g of the modified powder, disperse it into 0.6ml of deionized water, and ultrasonicate for 5 minutes;

[0037] 5. Slowly add 2ml of alcohol solution containing 0.1wt.% hydrochloric acid to make the titanium dioxide colloid into a viscous colloid;

[0038] 6. Use the screen printing method to coat a layer of slurry on the cleaned conductive glass, tear off the tape after natural d

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap