Station and method for measuring particulate contamination of a transport chamber for conveying and atmospherically storing semiconductor substrates

A technology of atmospheric pressure and measurement methods, applied in individual particle analysis, semiconductor/solid-state device manufacturing, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

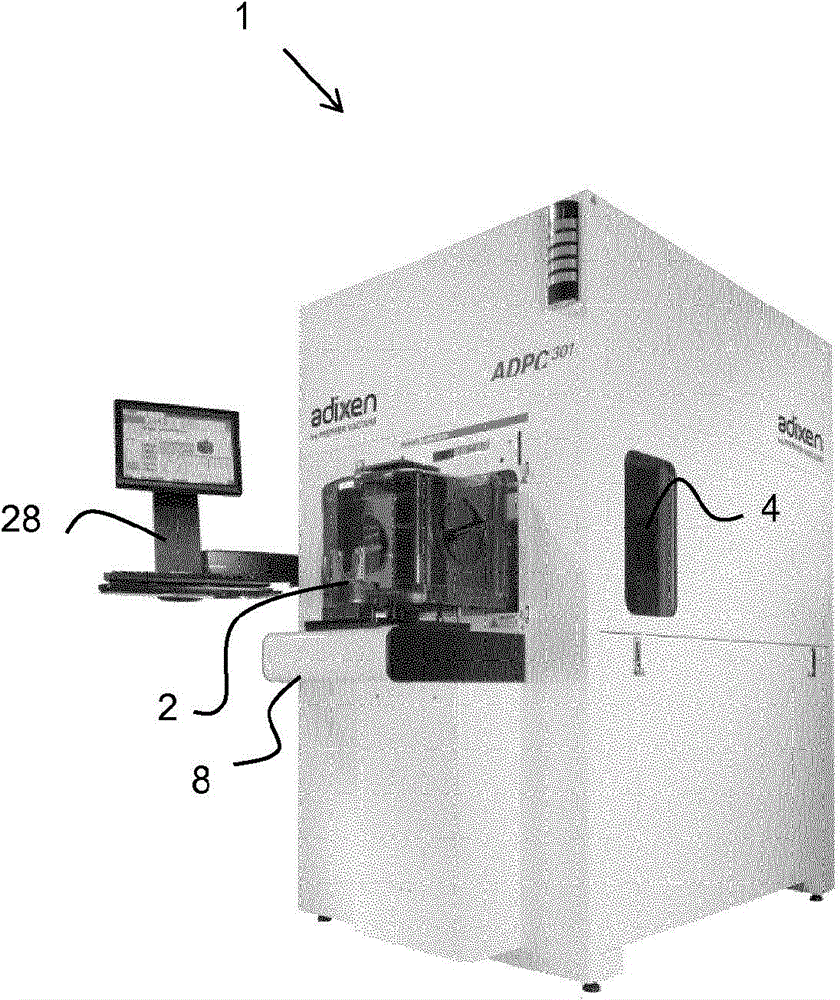

[0056] figure 1 Station 1 for measuring particle contamination is shown coupled to a FOUP transport carrier for transporting and storing semiconductor substrates at atmospheric pressure.

[0057] Although the figure shows a measurement station that can be coupled to a FOUP transport vehicle, the measurement station can be applied to other transport vehicles that transport and store semiconductor substrates under atmospheric pressure, such as, inter alia, standardized vehicles such as SMIF, FOSB, RSP or MRP.

[0058] These shipping vehicles have a confined air or nitrogen interior atmosphere at atmospheric pressure (ie, at a pressure substantially equal to the operating environment of the clean room, but isolated from the clean room).

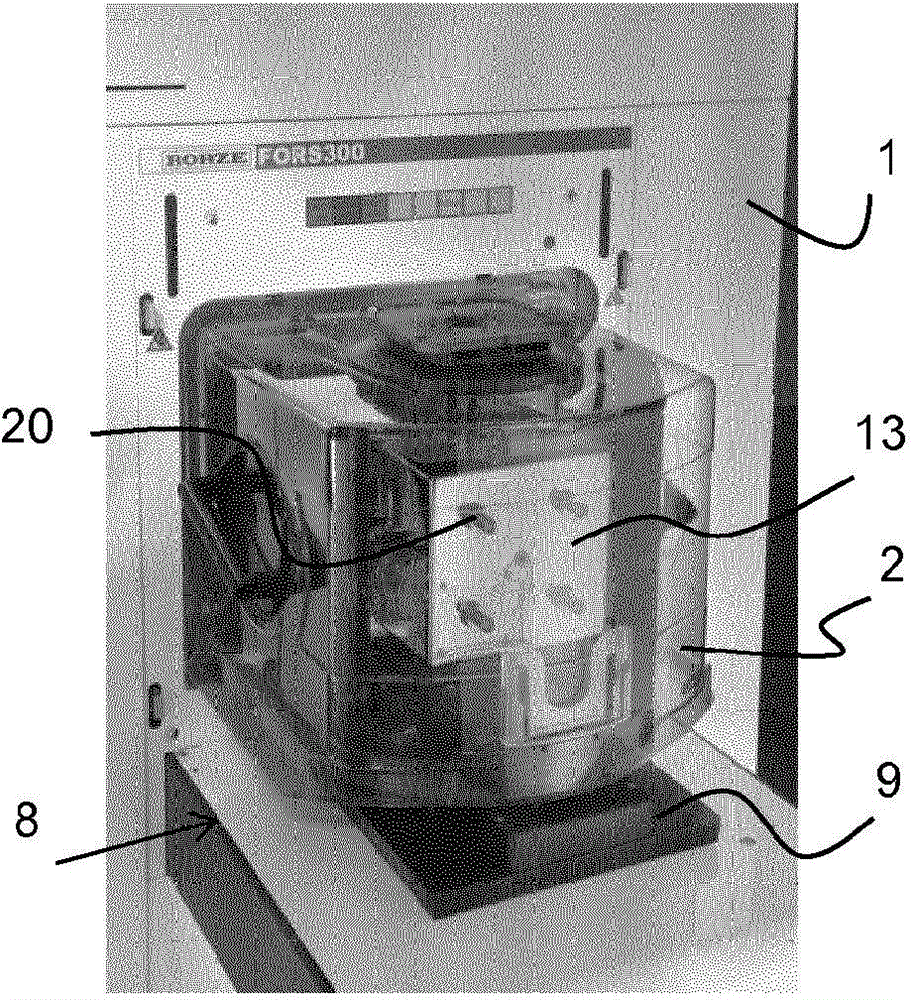

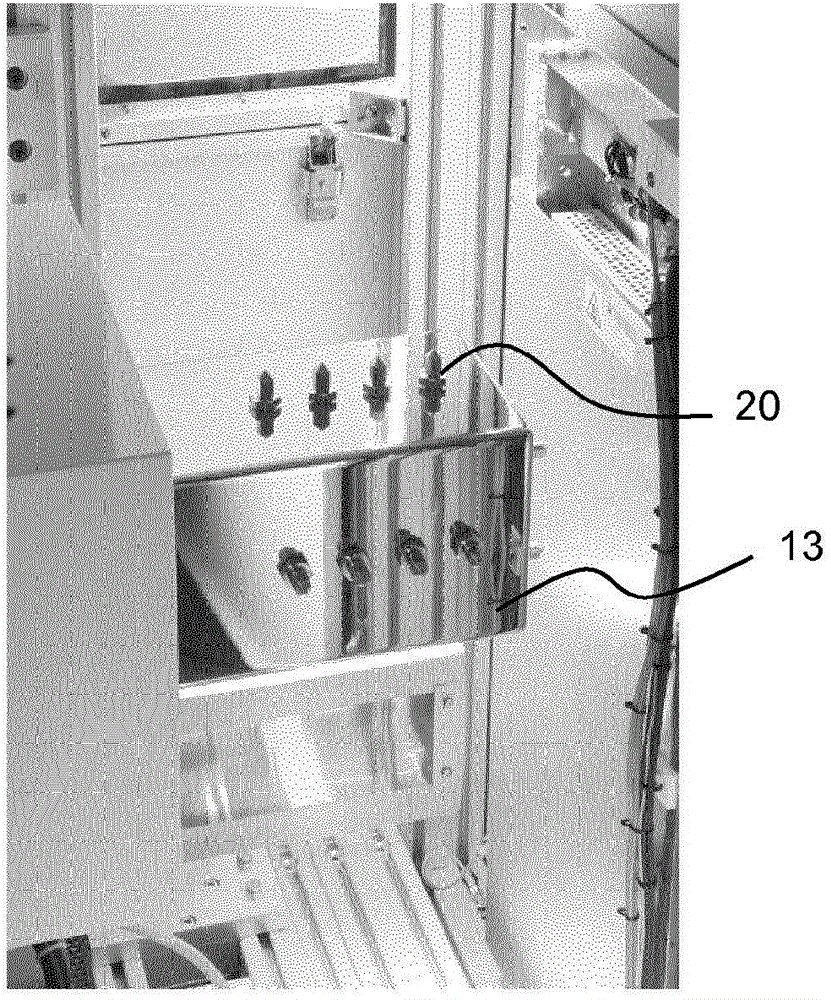

[0059] as available from figure 2 and 3a As seen in , the transport carrier comprises a peripheral rigid shell 2 having a generally substantially parallelepiped shape and comprising an aperture which can be closed with a movable door 3 and size

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap