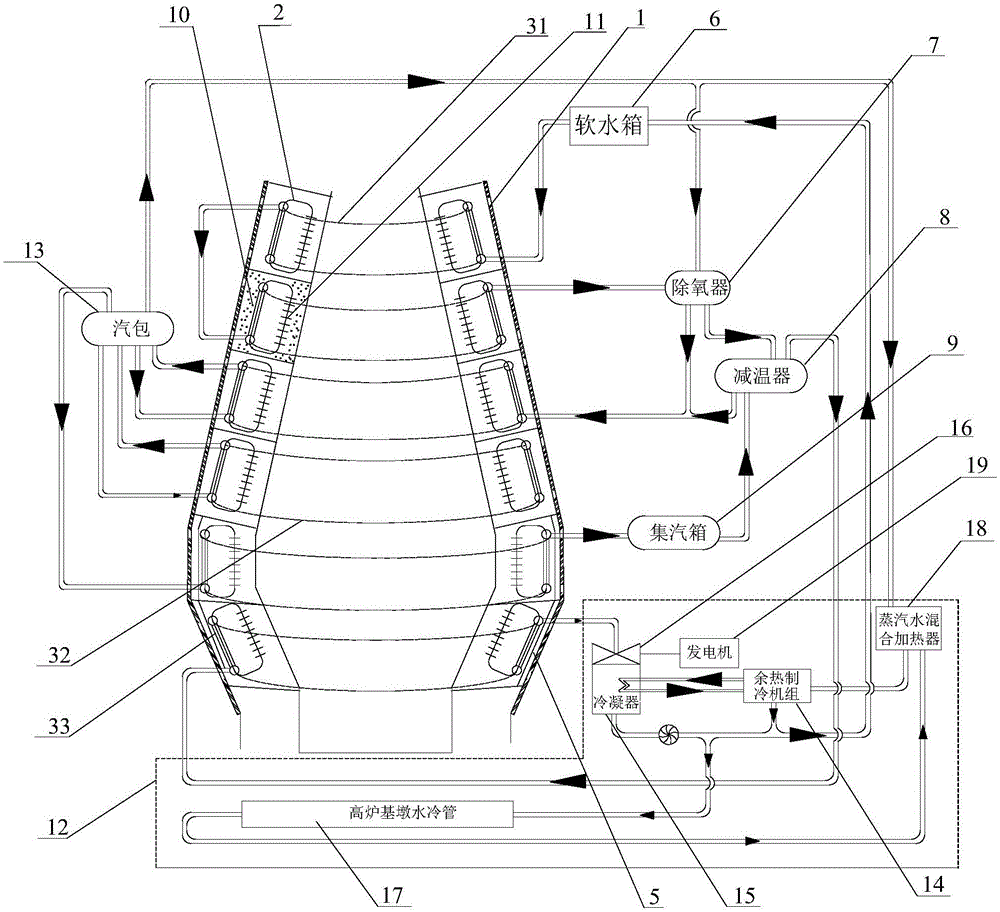

Energy saving control system based on superconduction cooling waste heat power generation of trilinear driving type blast furnace

An energy-saving control system and waste heat power generation technology are applied to blast furnace details, blast furnaces, blast furnace parts, etc., to achieve the effects of energy saving, high degree of automation, and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

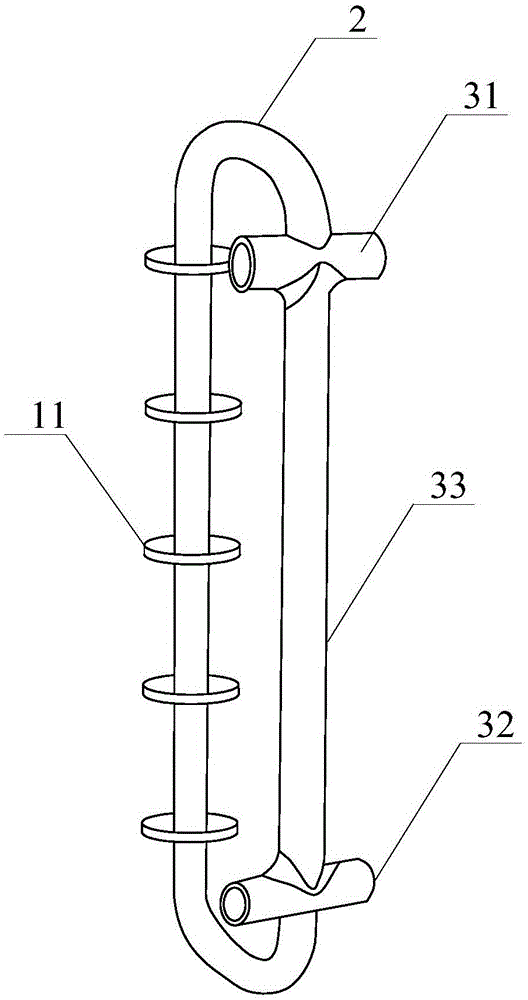

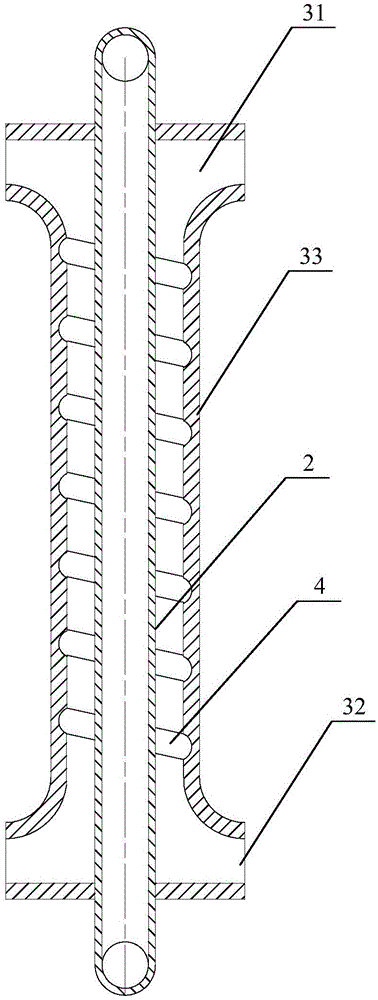

[0029] Such as Figure 1~3 As shown, the blast furnace body 1 of the present invention is the same as the traditional blast furnace, and is divided into four parts, the furnace shaft, the bosh, the furnace waist and the furnace seat. The present invention is provided with more than one superconducting annular heat exchange ring 2 in a layered and surrounding manner along the side wall of the blast furnace body 1, that is, these superconducting annular heat exchange rings 2 are arranged along the shaft and bosh of the blast furnace body 1. , the furnace waist and the furnace seat are arranged, and the side wall surface of the entire blast furnace body 1 is completely covered. Every circle around the side wall of the blast furnace body 1 is a layer, and the midline points of all superconducting annular heat exchange rings 2 on the same layer are in the same plane, so along the side wall surface of the blast furnace body 1 A superconducting annular heat exchange ring 2 with several

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap