Fastener hole centering drilling device for seat guide rail in lower pound column area of passenger-to-cargo airplane

A technology for seat guide rails and fastener holes, which is applied to aircraft parts, boring/drilling, drilling/drilling equipment, etc. It can solve problems such as poor work accuracy, low work efficiency, and seat jamming. Achieve the effects of improving processing efficiency, ensuring verticality, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

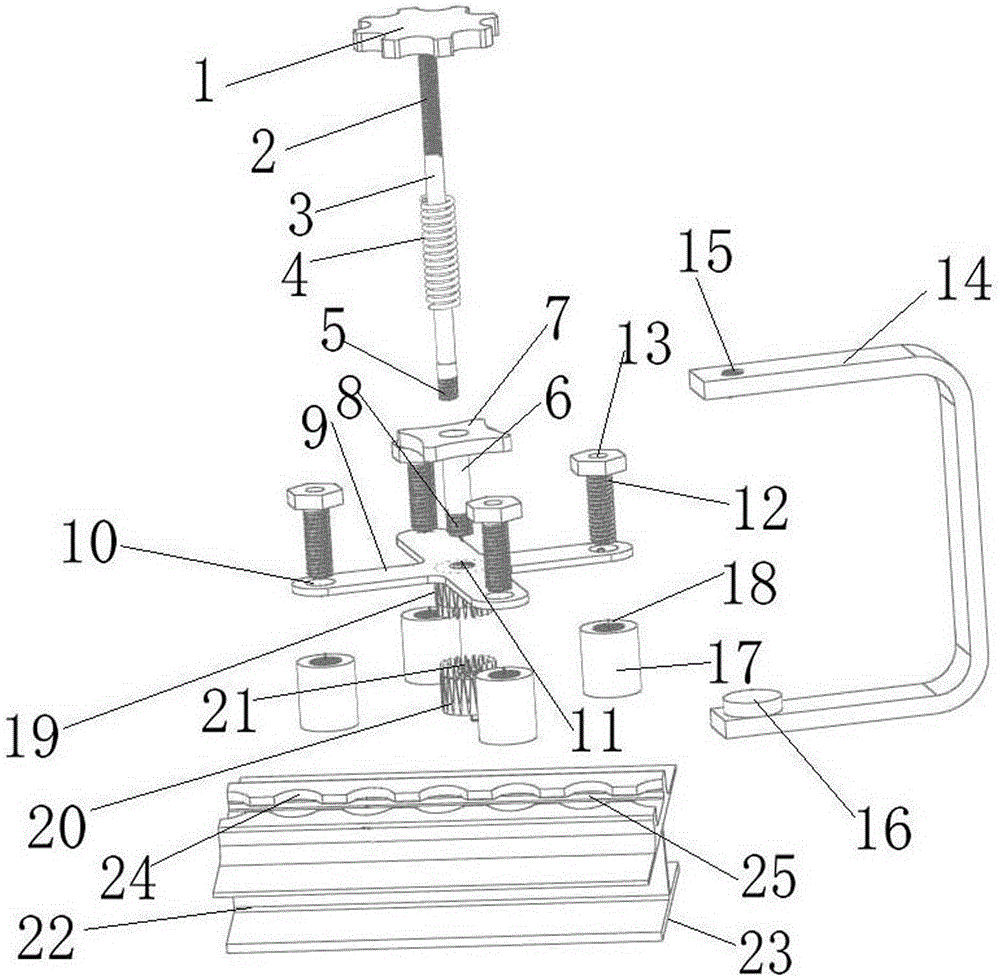

[0022] Attached below figure 1 The present invention will be further explained.

[0023] A centering and drilling device for seat rail fastener holes in the weighing post area of a passenger-to-cargo aircraft, comprising a bracket 14, the lower end of which is in contact with the lower end surface 23 of the rail profile of the seat rail profile 22; a center positioning device is arranged on the bracket In 14, the center positioning device is inserted into the circular clamping hole 24 of the seat rail profile 22; the reversing bracket 9 is horizontally rotated relative to the center positioning device;

[0024] N drilling positioning devices are uniformly installed on the reversing bracket 9 in the circumferential direction with the center of the center positioning device as the center. The drilling positioning device is provided with a guide hole 13 matching the drill bit along the axial direction. The drilling positioning device is vertical Straightly inserted into the circular c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap