Automatic adhesive paper sticking integrated machine and working method thereof

A working method and technology of an all-in-one machine, applied in metal processing and other directions, can solve the problems of restricting processing efficiency, blistering, and low gluing efficiency, and achieve the effect of high working efficiency and ensuring appearance accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

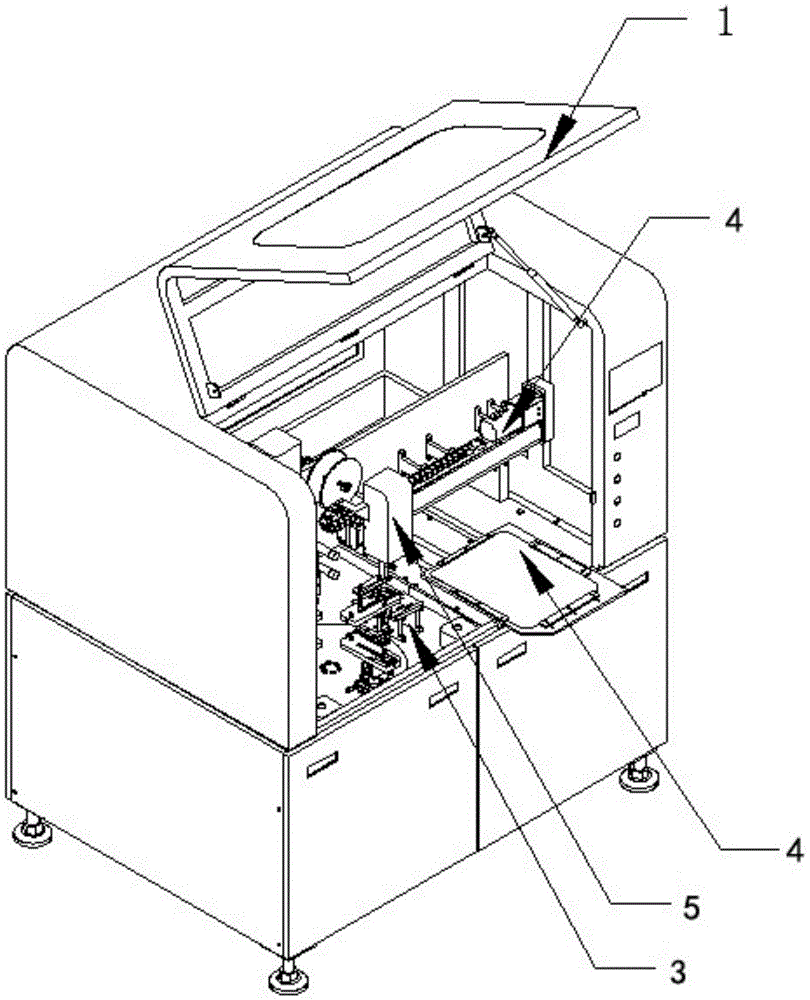

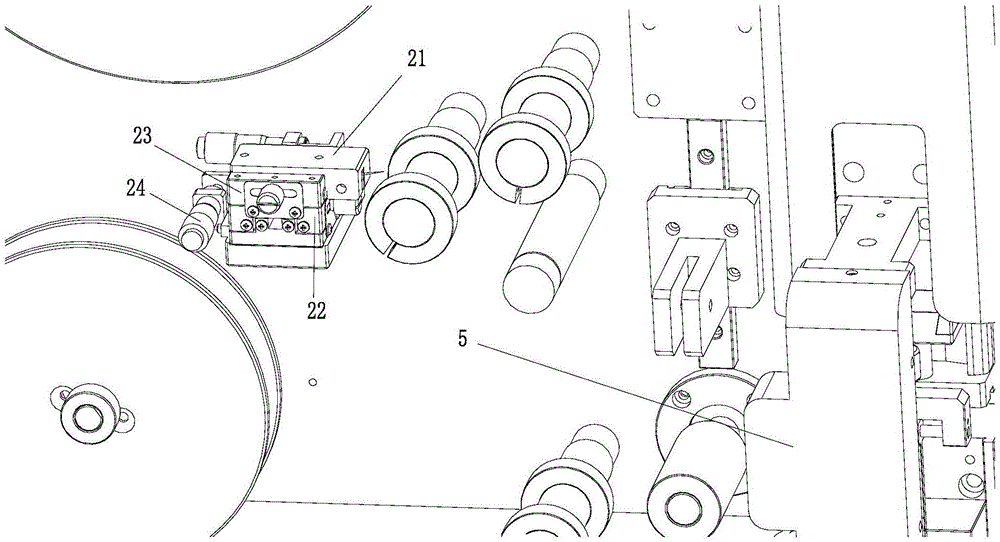

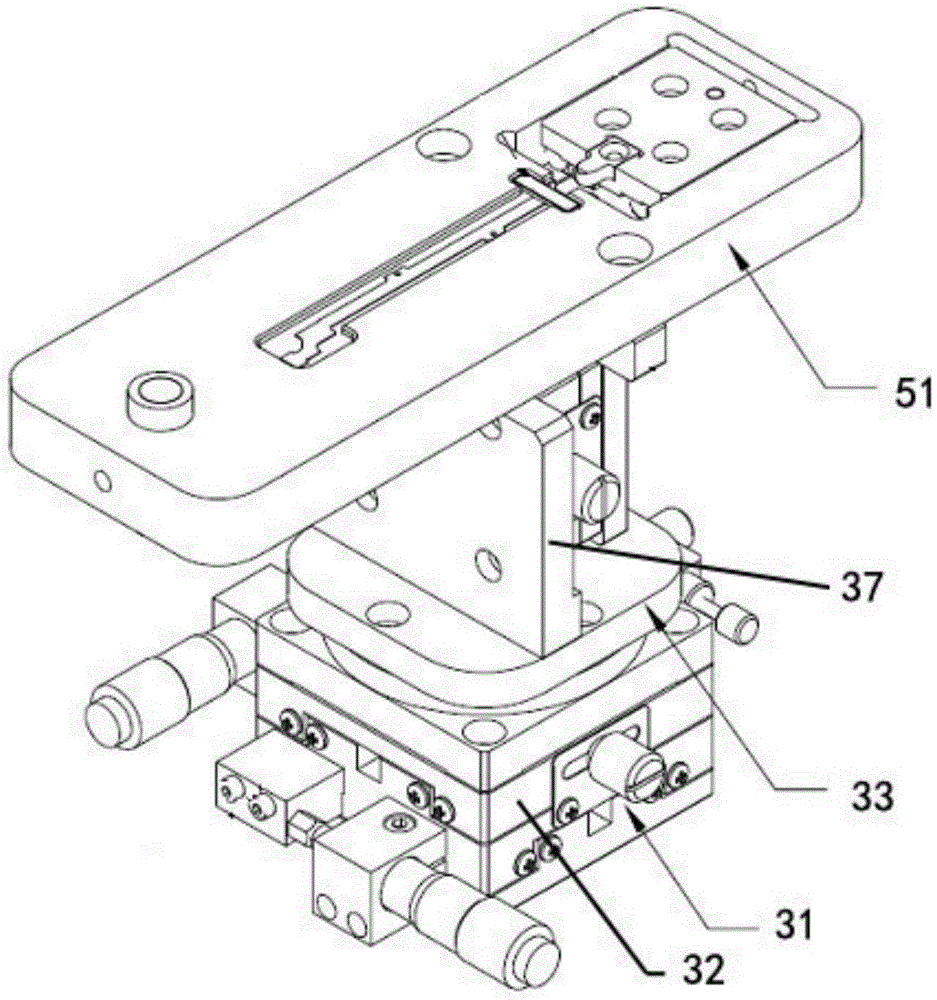

[0032] refer to Figure 1-10 , the automatic adhesive paper all-in-one machine of the present invention includes a machine platform 1, an adhesive paper cutting mechanism 2, an adhesive paper cutting and pasting mechanism 5, and a material retrieving adjustment mechanism 4, and it also includes a jig positioning adaptation mechanism 3. The glue The paper cutting and pasting mechanism 5 includes a positioning jig 51, a die-cutting module and a force-measuring alarm module 53. The upper surface of the positioning jig 51 is provided with a downwardly recessed product positioning groove 54 and an upwardly protruding pressure column 55. The force measuring alarm module 53 includes a double cylinder 56 and a load cell 57. The load cell 57 is located directly above the pressure column and fixed on the double cylinder to measure the pressure of the die-cutting in real time. The die-cu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap