Machining process

A mechanical processing and process technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of the processing effect needs to be improved, the processing speed needs to be improved, and the labor intensity is high, so as to reduce the labor intensity of the human body. , avoid operation, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

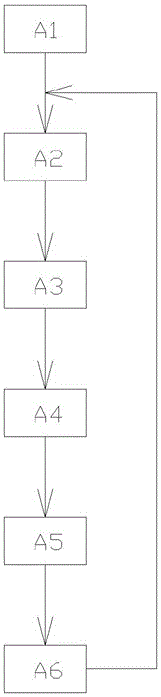

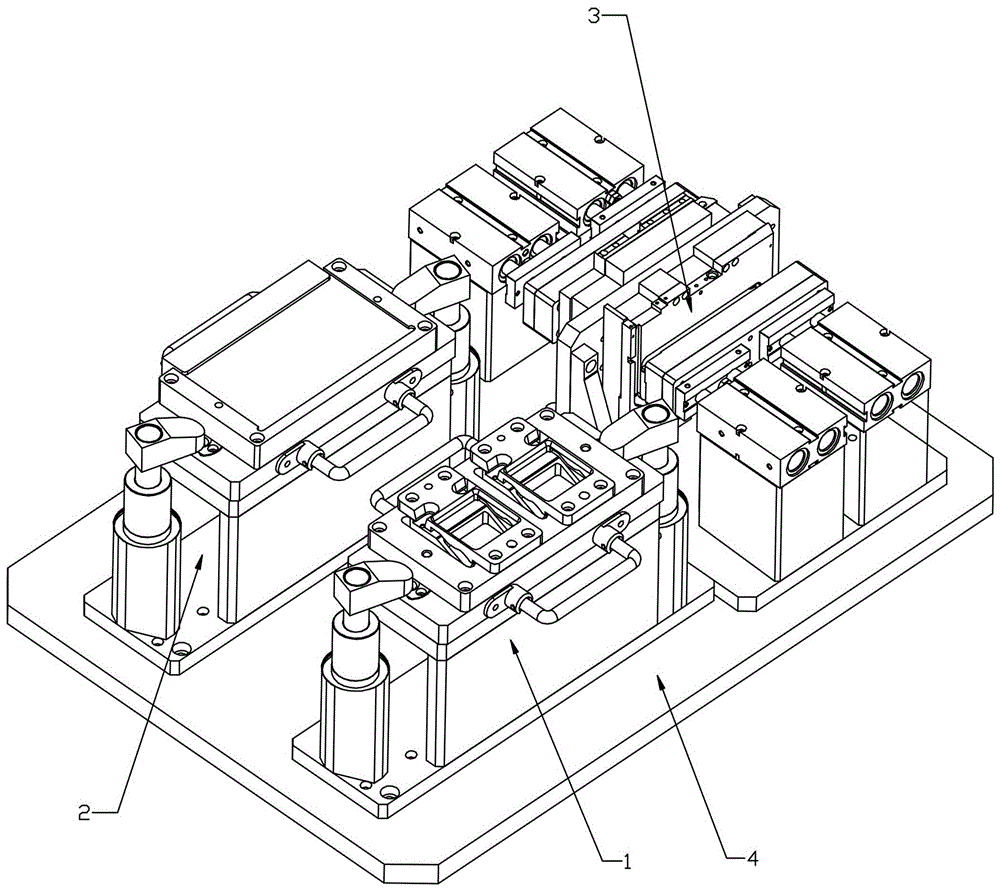

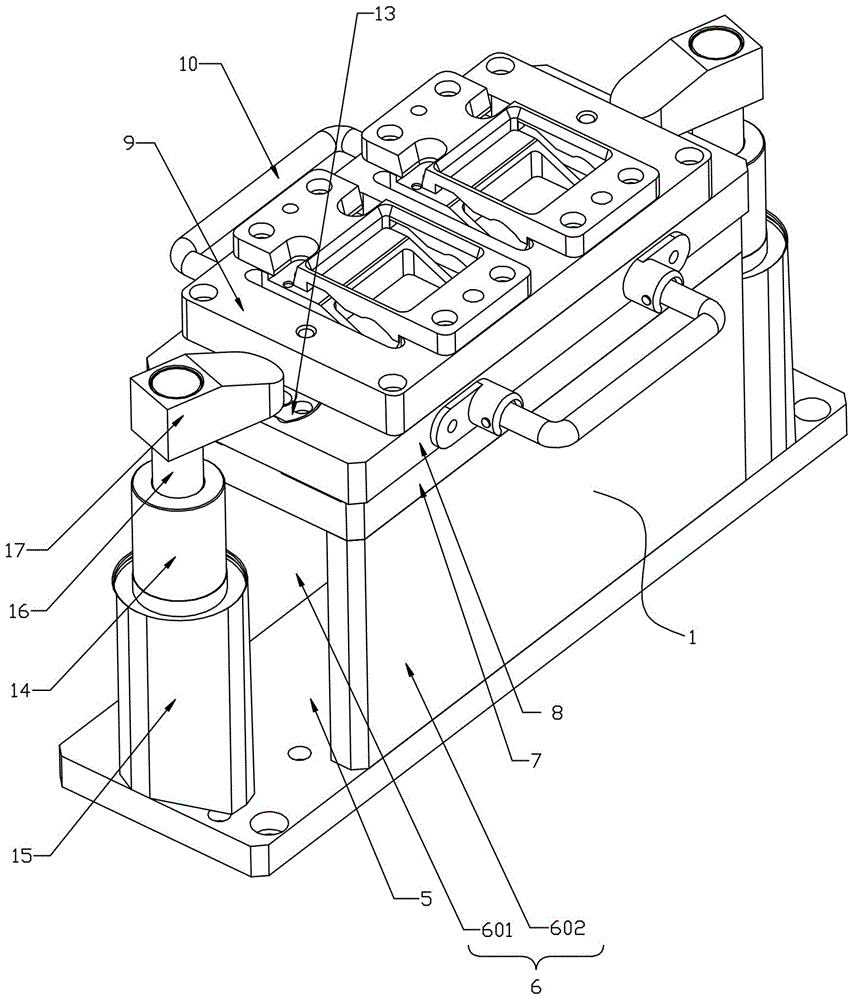

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, mechanical processing technology of the present invention, it comprises the following steps:

[0028] A1. Take out a number of workpieces that need to be processed and place them on the material preparation workbench for batching, and classify the workpieces. The workpieces that need to be processed on the front are the first type of workpieces, the workpieces that need to be processed on the reverse side are the second type of workpieces, and the workpieces that need to be processed on the side are The third type of workpiece, a CNC machine tool is placed next to the material preparation workbench. The CNC machine tool includes a frame, a control system fixed on the frame, and a lateral movement device fixed on the frame and electrically connected to the control system. , the longitudinal moving device fixedly installed on the horizontal moving device and electrically connected with the control d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap