Method for improving performance of AlSi9Cu2 aluminum alloy ingot

A technology of aluminum alloy ingots and alloys, applied in the field of aluminum alloys, can solve the problems of poor corrosion resistance, high defect rate, product cracking, etc., and achieve the effect of improving toughness and corrosion resistance, good toughness and corrosion resistance, and good feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by skilled personnel according to the present invention in practical applications still belong to the protection scope of the present invention.

[0025] The following examples are given to illustrate the invention.

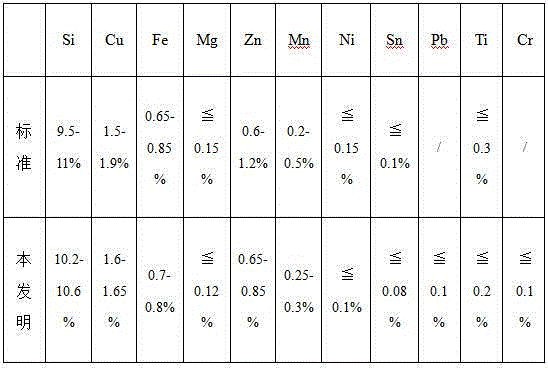

[0026] A kind of AlSi9Cu2 aluminum alloy ingot, its composition is represented as by mass fraction:

[0027] Si: 10.35%, Fe: 0.71%, Cu: 1.63%, Mn: 0.26%, Mg: 0.1%, Cr: 0.03, Ni: 0.03%, Zn: 0.76%, Ti: 0.05%, Pb: 0.02%, Sn :0.005%.

[0028] 4. The process for improving the toughness and corrosion resistance of the AlSi9Cu2 aluminum alloy ingot is as follows:

[0029] In addition to aluminum, the alloy composition mainly contains the following components by weight percentage:

[0030]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap