Fast multi-sintering additive manufacturing device and method

An additive manufacturing and fast technology, applied in the field of rapid multi-sintering additive manufacturing equipment, can solve the problems of low initial molding strength, difficult molding of functional parts, slow molding speed, etc., to improve precision, increase molding speed, and improve molding The effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The basic structure of powder additive manufacturing equipment, powder handling, powder storage, powder delivery, powder laying, and the model slices involved in the additive manufacturing method to generate the molding area of each layer and the principle of layered construction are well-known technologies and will not be repeated here. .

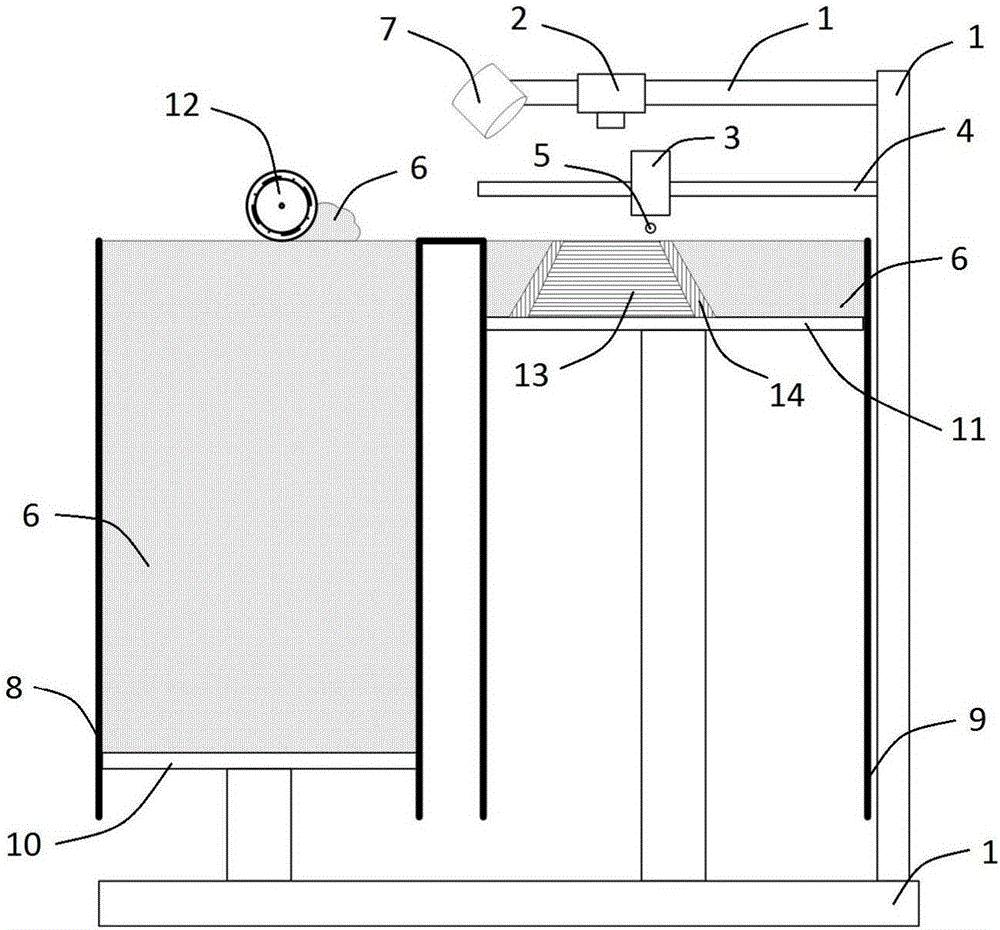

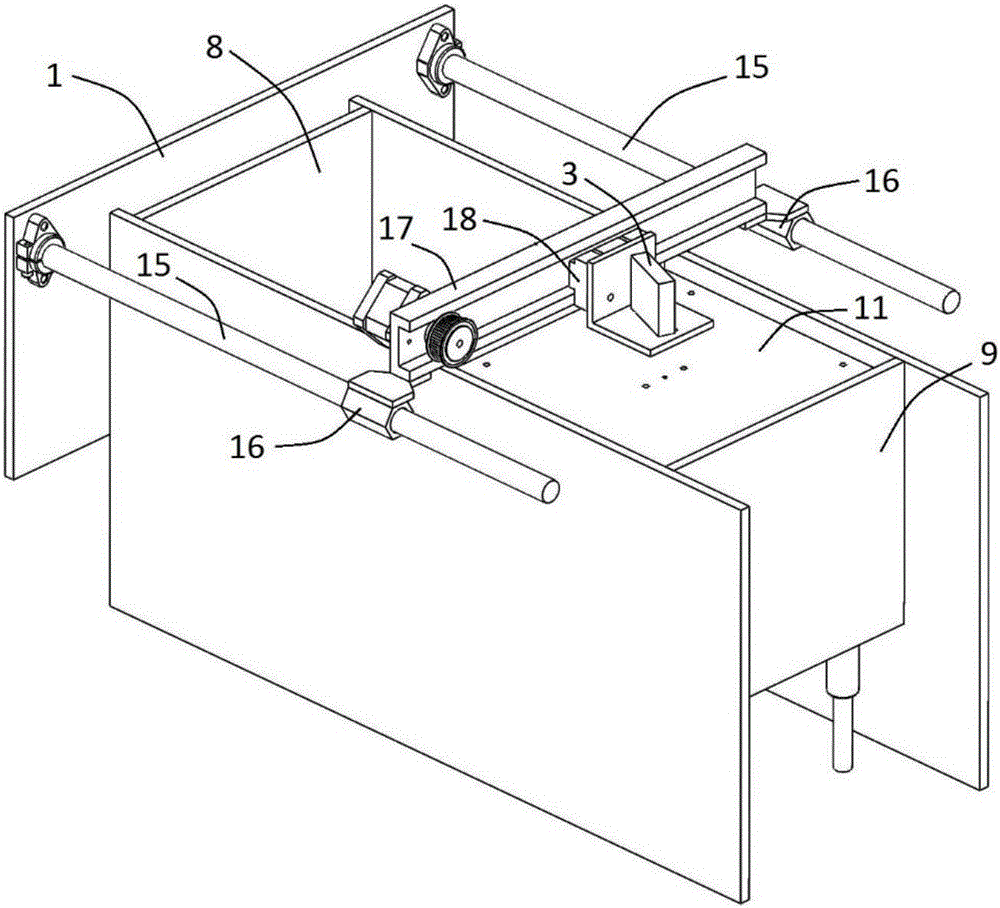

[0032] Such as figure 1 As shown, the rapid multi-sintering additive manufacturing equipment of the present invention is composed of a powder bed subsystem, a laser scanning subsystem, an inkjet printing subsystem and a thermal radiation source 7 installed on a frame 1 .

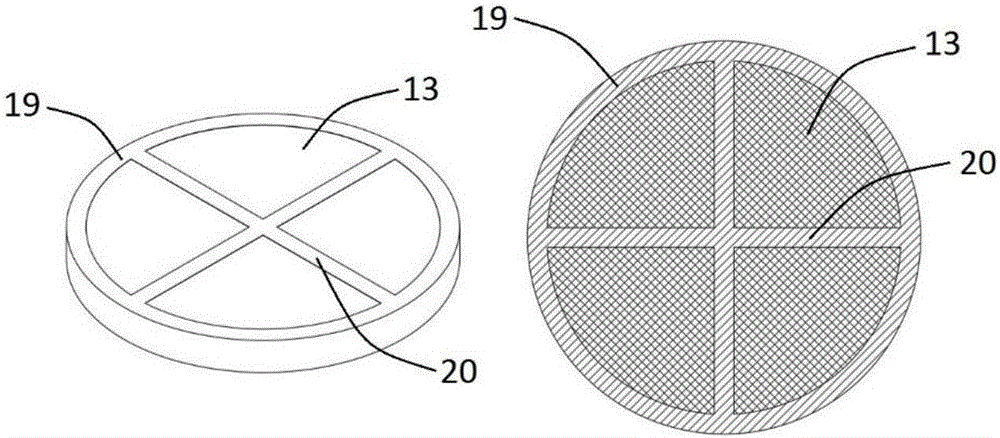

[0033] The powder bed subsystem includes a vertical lifting molding platform 11, a powder conveying device and a powder laying device 12; the powder conveying device is composed of a powder storage chamber 8 and a powder pushing platform 10; the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap