Smashing equipment for solid wastes obtained by ceramic roasting

A technology of solid waste and crushing equipment, applied in the direction of grain processing, etc., can solve the problems of inability to classify and crush, affecting the normal operation of crushing devices, crushing structure and blockage of discharge openings, etc., to ensure quality and effect, improve crushing efficiency, prevent damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

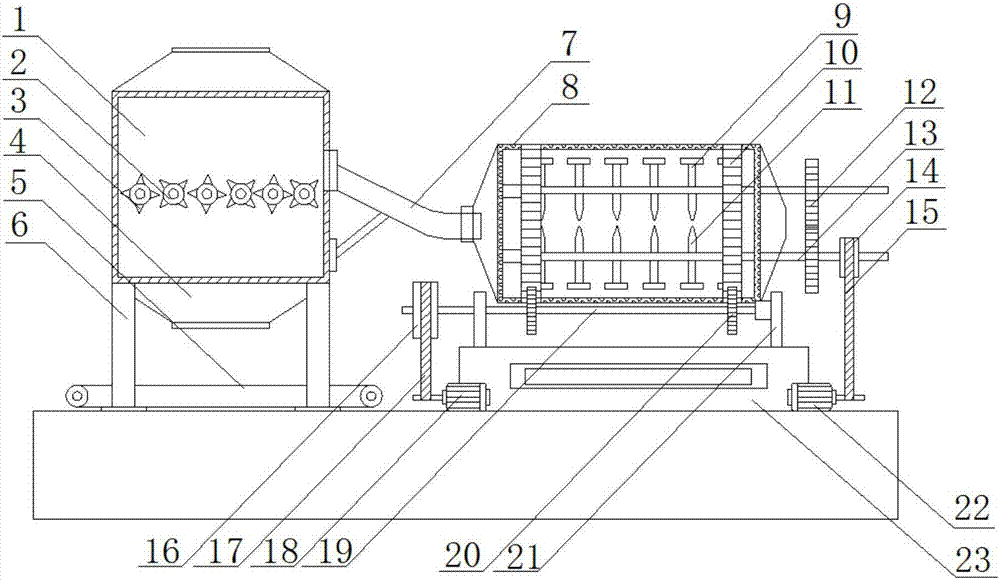

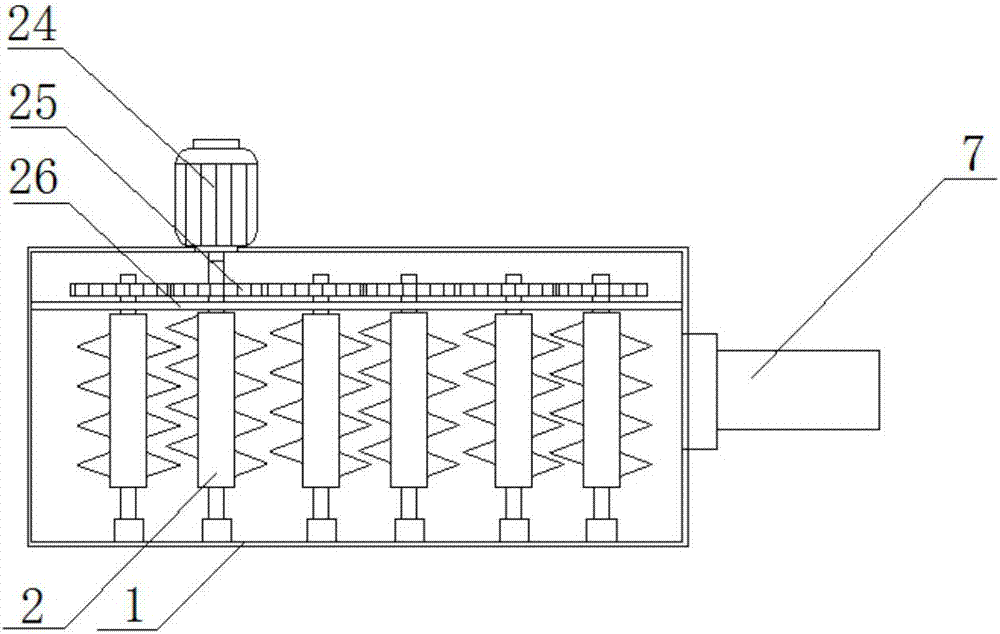

[0014] Reference Figure 1-2 , A solid waste crushing equipment used for ceramics roasting, including a base. The upper side of the base is provided with four support columns 6 and the upper end of the support column 6 is provided with a crushing box 1. In the crushing box 1 Ceramic waste is crushed. The upper end of the crushing box 1 is provided with a first inlet. The crushing box 1 is vertically provided with a partition 26. The partition 26 divides the crushing box 1 into a rotating cavity and a crushing cavity. A first driving device 24 is provided on the side. The output shaft of the first driving device 24 penetrates the side wall of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap