Waste plastic pipe crushing machine

A plastic pipe and crusher technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of high labor intensity, low production efficiency, injury to people, etc., to reduce labor intensity and reduce bolt falling. , The effect of high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] The present invention will be described in detail below in conjunction with the drawings and specific implementations:

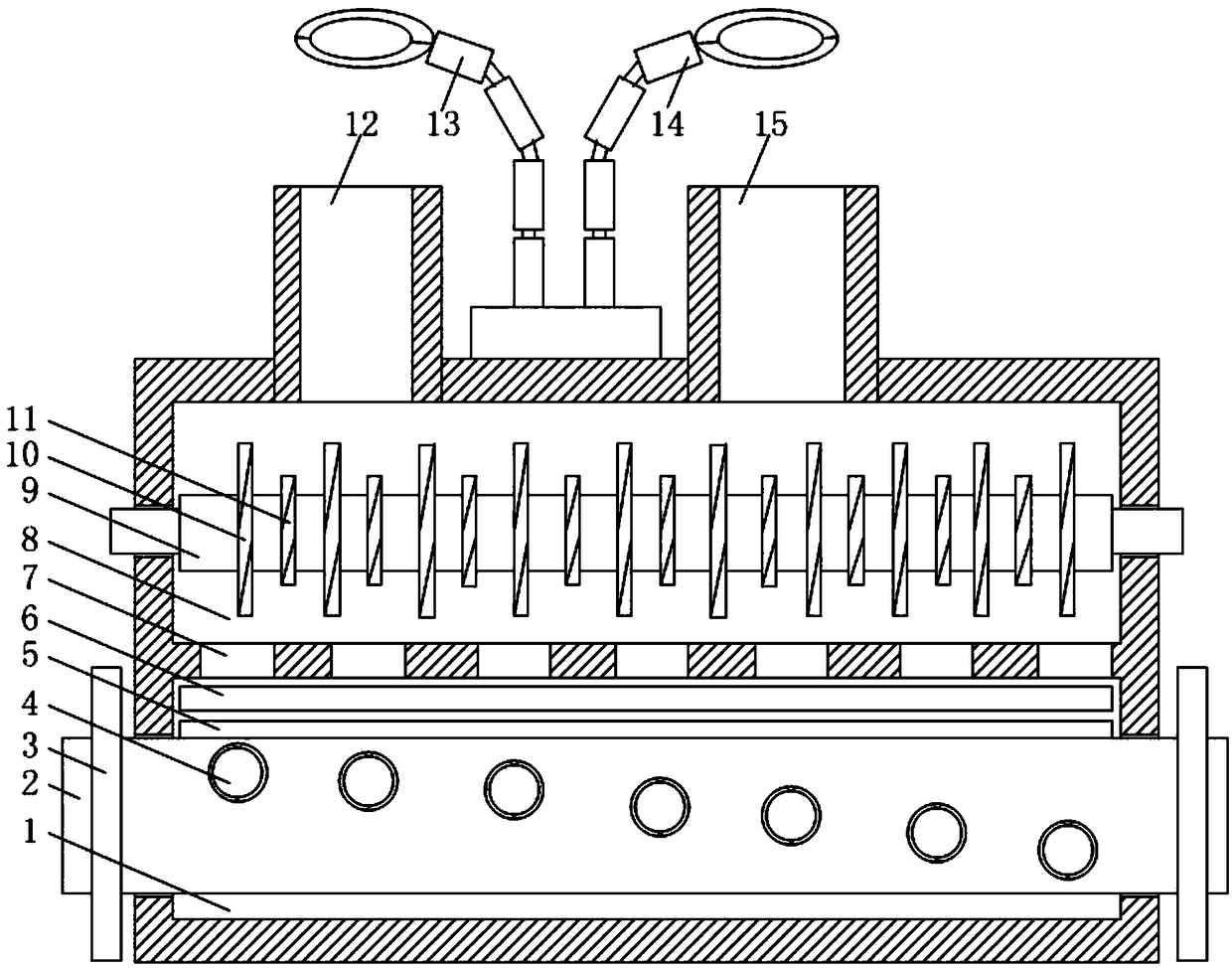

[0019] Such as figure 1 As shown, the waste plastic pipe crusher of the present invention includes a mechanical arm, a feed pipe, a crushing box, a knife holder roller, a disc knife, a magnet, a square knife, a discharge roller and a variable frequency speed regulating motor.

[0020] The mechanical arm is fixed on the top of the crushing box, and the mechanical arm includes multiple sections. A chuck is arranged at the top of the mechanical arm for clamping waste plastic pipes. A control box is arranged at the bottom of the robotic arm, and a hydraulic pump is arranged in the control box. The control box uses the power of the hydraulic pump to control the gripping, propulsion, expansion, and bending of the robotic arm. The mechanical arm replaces manual manual loading, which is safer and reduces labor intensity.

[0021] The feed pipe is arranged under the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap