Non-condensable gas collecting and spraying energy-saving device of evaporator set

An energy-saving device and evaporator technology, which is applied in the direction of steam condensation, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of large vacuum fluctuations, large energy consumption, and difficult stable control of the evaporator group in the system, so as to improve adhesion , energy saving, high biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

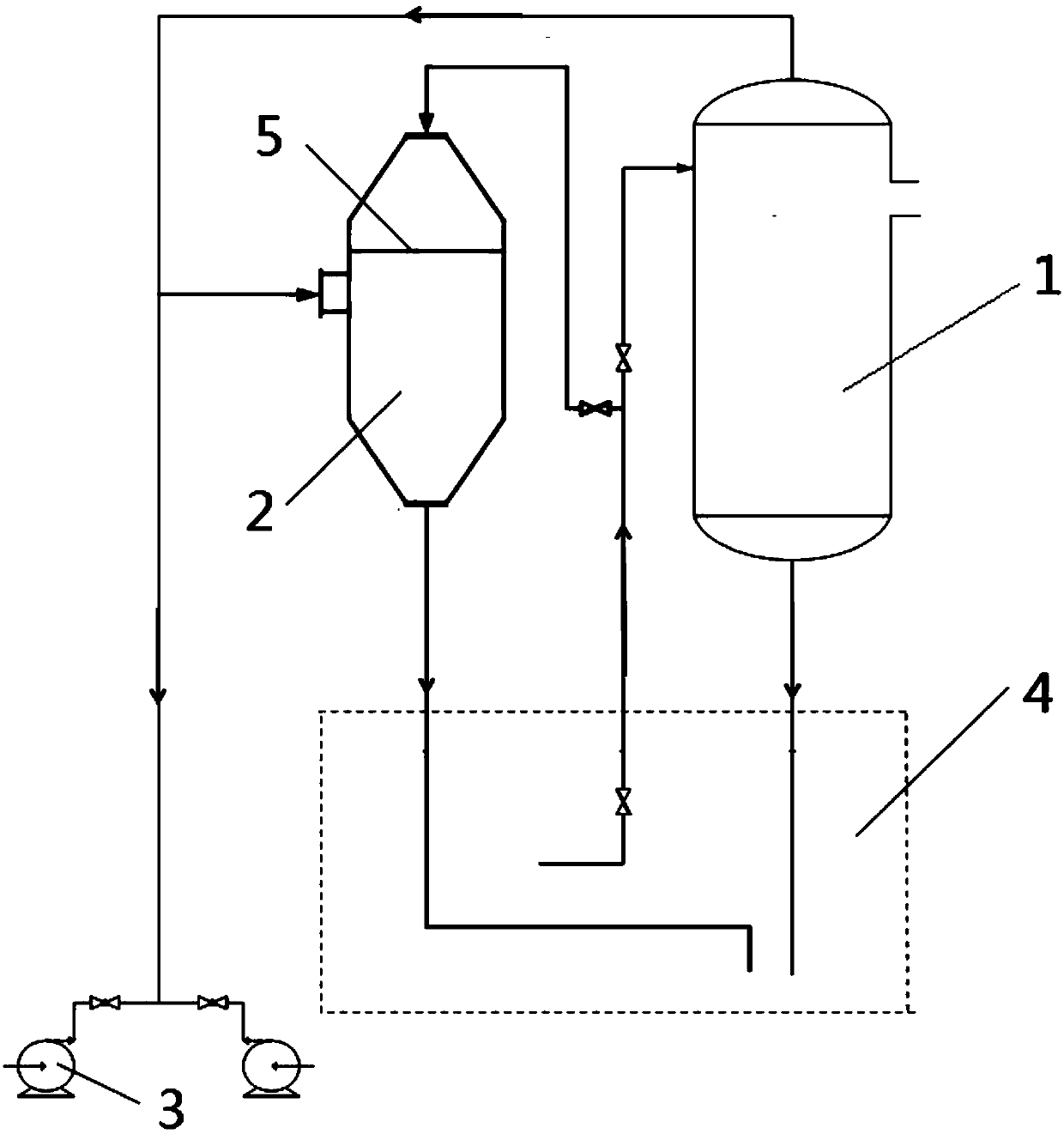

[0036] Such as figure 1 , figure 2 As shown, the non-condensable gas collection and injection energy-saving devices of the evaporator group include:

[0037] The vertically placed cooling tank 2 is used to collect spray condensed non-condensable gas, and its top and bottom are truncated cones, and the middle part is a cylinder; A nozzle is provided; an orifice 5 is also arranged above the nozzle on the side wall of the middle part of the cylinder and below the nozzle on the top of the truncated cone;

[0038] The vertically placed water cooler 1 has nozzles on its top, bottom and upper side walls;

[0039]Vacuum pump 3, which is connected to the nozzle of the side wall of the middle part of the cooling tank 2 cylinder and the nozzle at the top of the water cooler 1 through pipelines;

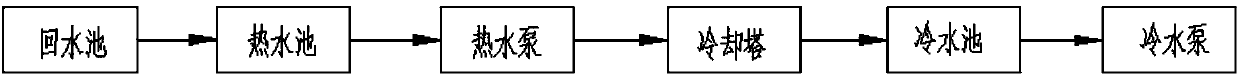

[0040] The evaporative circulating water system 4 includes a backwater pool, a hot water pool, a hot water pump, a cooling tower, a cold water pool and a cold water pump; The main pipeline of

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap