Method for cultivating ganoderma lucidum with eucalyptus processing residues as main cultivating material

A technology for processing residues and cultivation materials, applied in the field of Ganoderma lucidum cultivation, which can solve problems such as high raw material costs, unfavorable factory production management, and unfixed composition of miscellaneous sawdust raw materials, so as to reduce production costs, reduce environmental pollution, and promote common health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

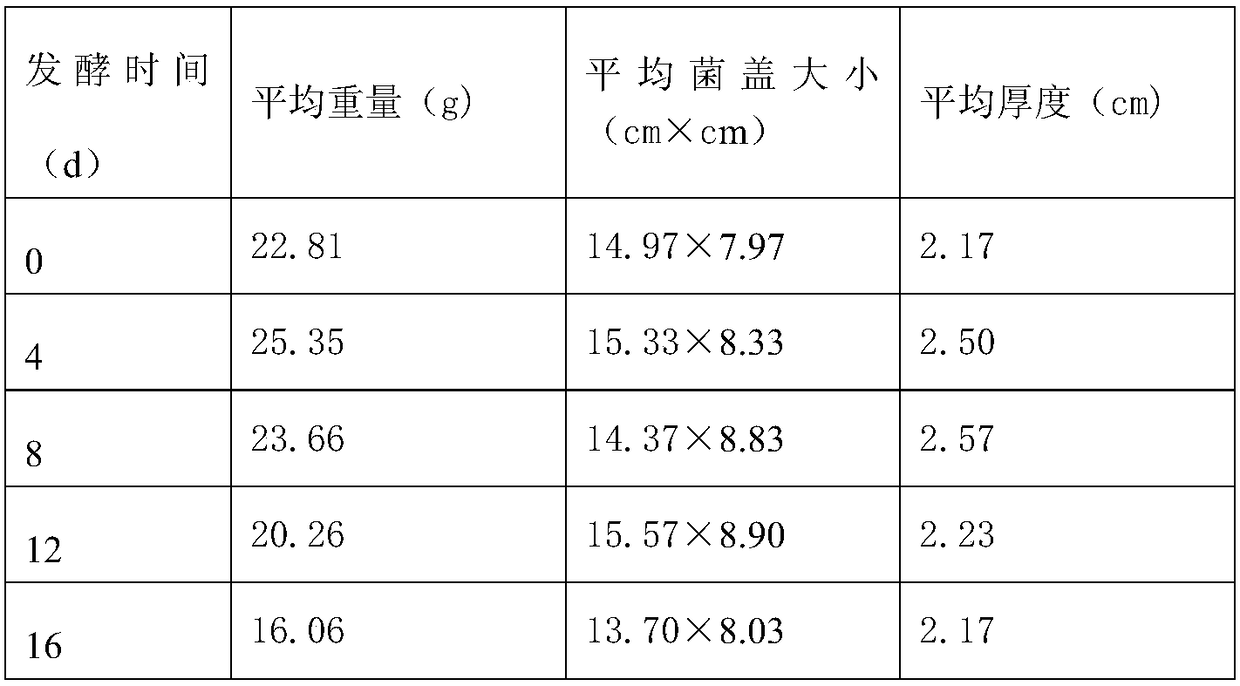

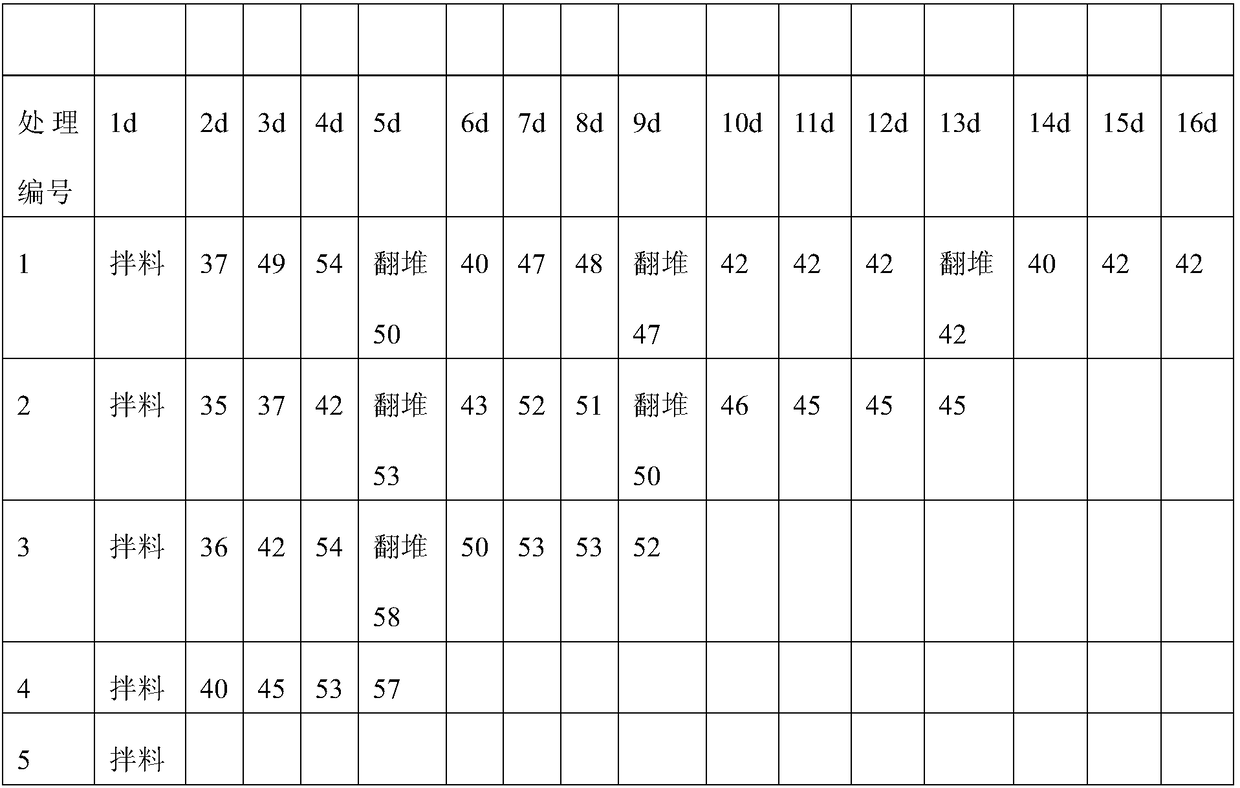

[0017] Example 1:

[0018] The method for cultivating Ganoderma lucidum with eucalyptus processing residue as the main cultivating material, comprises the following steps:

[0019] The method for cultivating Ganoderma lucidum with eucalyptus processing residue as main cultivating material is characterized in that: comprising the following steps:

[0020] (1) pretreatment: the eucalyptus wood chips are crossed through a 5 mesh sieve to remove impurities, dried for subsequent use; the fresh eucalyptus bark is processed and pulverized into a 5cm long section, dried in the sun, to obtain the eucalyptus bark, for subsequent use;

[0021] (2) Preparation of materials: in parts by weight, prepare the following raw materials: 45 parts of eucalyptus sawdust, 20 parts of eucalyptus bark, 15 parts of cottonseed hulls, 10 parts of wheat bran, 1 part of superphosphate, 1 part of gypsum and 0.1 part of warming starter ;

[0022] (3) Mixing and fermentation: according to the formula of step (

Example Embodiment

[0027] Example 2:

[0028] The method for cultivating Ganoderma lucidum with eucalyptus processing residue as main cultivating material is characterized in that: comprising the following steps:

[0029] (1) pretreatment: the eucalyptus wood chips are crossed through a 5 mesh sieve to remove impurities, and dried for subsequent use; the fresh eucalyptus bark is processed and pulverized into a 6cm long section, dried in the sun, to obtain the eucalyptus bark, for subsequent use;

[0030] (2) Preparation of materials: in parts by weight, prepare the following raw materials: 50 parts of eucalyptus sawdust, 20 parts of eucalyptus bark, 18 parts of cottonseed husks, 11 parts of wheat bran, 1 part of superphosphate, 1 part of gypsum and 0.15 part of warming starter ;

[0031] (3) Mixing and fermentation: according to the formula of step (2), dry mix all the raw materials except the wheat bran, add water to adjust the humidity, make the water content reach 62%, and adjust the pH value o

Example Embodiment

[0036] Example 3:

[0037] The method for cultivating Ganoderma lucidum with eucalyptus processing residue as main cultivating material is characterized in that: comprising the following steps:

[0038] (1) pre-treatment: the eucalyptus sawdust is crossed through a 5 mesh sieve to remove impurities, and dried for subsequent use; the fresh eucalyptus bark is processed and pulverized into 8cm long sections, dried in the sun, to obtain the eucalyptus bark, for subsequent use;

[0039] (2) Preparation of materials: in parts by weight, prepare the following raw materials: 48 parts of eucalyptus sawdust, 20 parts of eucalyptus bark, 16 parts of cottonseed husks, 12 parts of wheat bran, 1 part of superphosphate, 1 part of gypsum and 0.2 part of warming starter ;

[0040] (3) Mixing and fermentation: according to the formula of step (2), dry mix all the raw materials except the wheat bran, add water to adjust the humidity, make the water content reach 64%, and adjust the pH value of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap