Preparation method of ultra-large-specification high-Mg aluminum alloy round ingot

An ultra-large-sized, aluminum alloy technology, which is applied in the field of preparation of ultra-large-sized high-Mg aluminum alloy ingots, can solve the problems of poor quality of aluminum alloy ingots, high production costs, low production qualification rate, etc. The probability of ingot cracking and the effect of improving production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

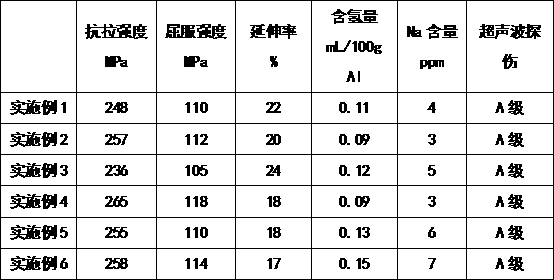

Examples

Embodiment 1

[0030] A method for preparing a super-large high-Mg aluminum alloy round ingot, comprising the following steps:

[0031] S1. Dosing according to the following alloy components by weight percentage: Mg4.5%, Mn0.6%, Cr 0.1%, Be 0.0005%, Ti0.1%, Zn≤0.2%, Cu≤0.10%, Fe≤0.30%, Si≤0.25%; others are Al and some unavoidable impurity elements.

[0032] S2. Melting: According to the calculated results of the ingredients, start feeding, first add remelted aluminum ingots, 5xxx aluminum alloy return materials, and magnesium ingots into the smelting furnace. Heat in the melting furnace until the charge is melted, stir for 50 minutes, the melting temperature is 730°C, and the melting time is 8 hours.

[0033] S3. After the smelting is completed, the molten aluminum is transferred to the holding furnace for heat preservation. The temperature of the heat preservation furnace is controlled at 720 ° C, and the heat preservation time is 4 hours. Adjust the composition of the magnesium ingot, then

Embodiment 2

[0039] Example 2

[0040] A method for preparing a super-large high-Mg aluminum alloy round ingot, comprising the following steps:

[0041] S1. Dosing according to the following alloy components by weight percentage: Mg4.9%, Mn0.8%, Cr 0.2%, Be 0.0015%, Ti0.1%, Zn≤0.2%, Cu≤0.10%, Fe≤0.30%, Si≤0.25%; others are Al and some unavoidable impurity elements.

[0042] S2. Melting: According to the calculated results of the ingredients, start feeding, first add remelted aluminum ingots, 5xxx aluminum alloy return materials, and magnesium ingots into the smelting furnace. Heat in the melting furnace until the charge is melted, stir for 60 minutes, the melting temperature is 750°C, and the melting time is 8 hours.

[0043] S3. After the smelting is completed, transfer the molten aluminum to the holding furnace for heat preservation. The temperature of the heat holding furnace is controlled at 730°C, and the heat preservation time is 4 hours. Adjust the composition of magnesium ingots, t

Embodiment 3

[0049] A method for preparing a super-large high-Mg aluminum alloy round ingot, comprising the following steps:

[0050] S1. Dosing according to the following alloy components by weight percentage: Mg4.0%, Mn1.0%, Cr 0.05%, Be0.0015%, Ti0.15%, Zn≤0.25%, Cu≤0.10%, Fe≤0.40% , Si≤0.40%; others are Al and some unavoidable impurity elements.

[0051] S2. Melting: According to the calculated results of the ingredients, start feeding, first add remelted aluminum ingots, 5xxx aluminum alloy return materials, and magnesium ingots into the smelting furnace. Heat in the melting furnace until the charge is melted, stir for 60 minutes, the melting temperature is 710°C, and the melting time is 6 hours.

[0052] S3. After the smelting is completed, the molten aluminum is transferred to the holding furnace for heat preservation. The temperature of the heat holding furnace is controlled at 700 ° C, and the heat preservation time is 3 hours. Adjust the composition of magnesium ingots, then add A

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap