Device and method for testing electrical parameters of silicon-germanium/silicon multi-quantum well infrared sensitive material

A technology of multiple quantum wells and sensitive materials, which is applied in the field of electrical parameter testing devices of silicon germanium silicon multiple quantum wells infrared sensitive materials, can solve the problems that the four-probe method cannot be used to test the electrical properties of quantum well materials, etc., so as to improve the testing efficiency , The effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

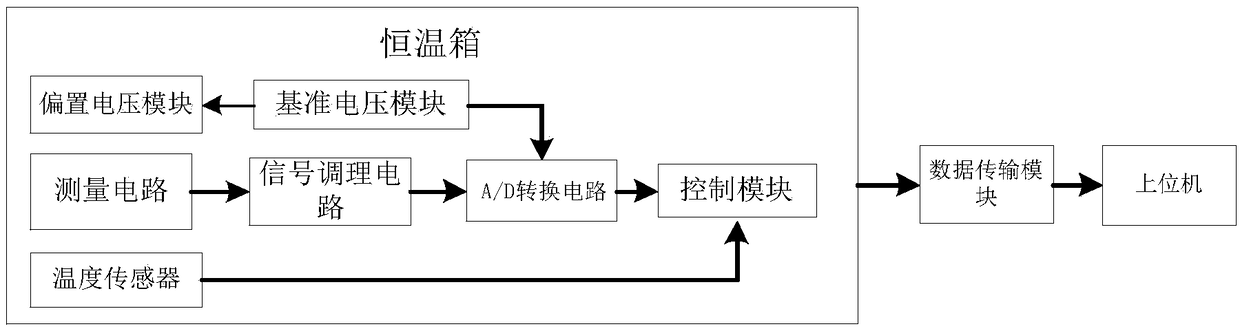

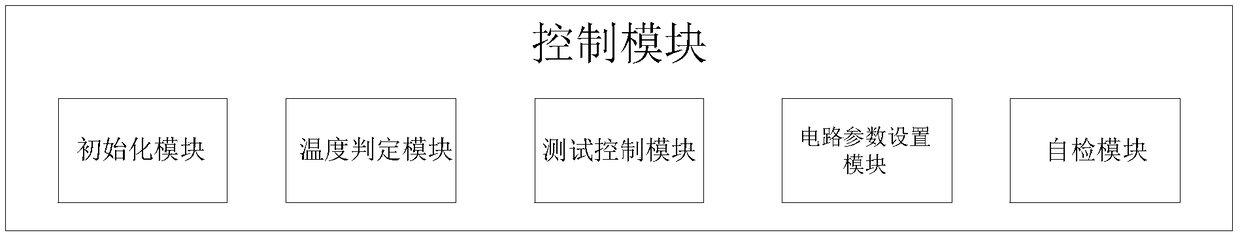

Method used

Image

Examples

Embodiment

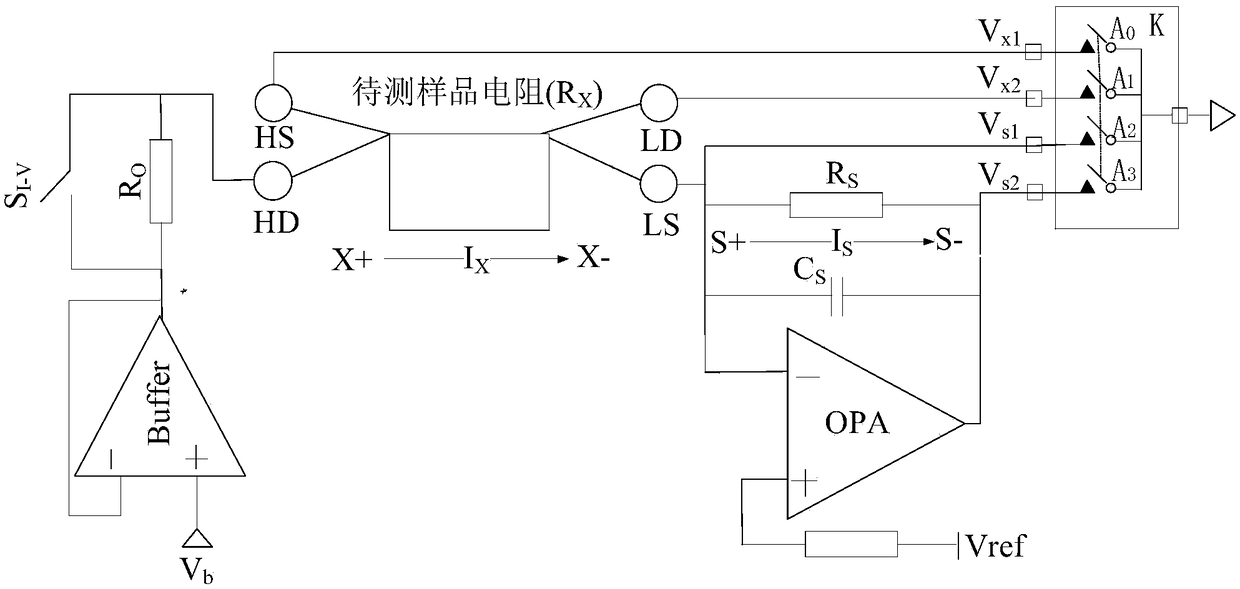

[0117] Step 1, performing MEMS process on a silicon-germanium-silicon multi-quantum well infrared sensitive material to obtain a material to be tested containing a test electrode;

[0118] combine Figure 4 The silicon germanium silicon multi-quantum well infrared sensitive material structure includes bottom contact layer, bottom isolation layer, silicon germanium / silicon multi quantum well structure and top contact layer in sequence from bottom to top. The silicon germanium / silicon multiple quantum well structure is composed of undoped single crystal silicon germanium layer and undoped single crystal silicon layer. The single crystal silicon germanium layer is adjacent to the top isolation layer and the bottom isolation layer respectively. The thickness of the crystalline silicon germanium layer (well) is 10nm, the mass content of germanium is 30%, the thickness of the single crystal silicon layer (barrier) is 30nm, and the number of silicon germanium / silicon cycles is 4 l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap