Multilayered co-extruded high-temperature boiling-resistant high barrier film

A multi-layer co-extrusion, high temperature resistant technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of difficult extrusion molding, barrier film not resistant to high temperature, high material cost, etc., to achieve The effect of improving the pass rate and good deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

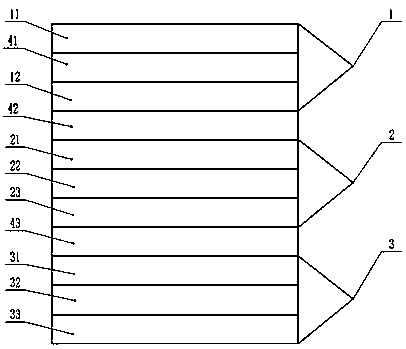

[0022] Such as figure 1 As shown, a multi-layer co-extruded high-temperature cooking high-barrier film. The barrier film includes an inner layer 1, a barrier layer 2 and an outer layer 3. The inner layer 1 includes PA layer 11 and PP layer 12, PA layer 11 and The PP layer 12 is rolled through the adhesive layer 41 to obtain the inner layer 1. The PA layer 11 in the inner layer 1 is composed of the following components by weight: 50 parts of silicone resin, 10 parts of aluminum hydroxide, and carbonic acid 5 parts of potassium, 1 part of XC-99-B5654 silicone flame retardant, 0.3 parts of polycaprolactam, PP layer 12 is composed of the following components by weight: 100 parts of chlorinated modified polypropylene, 15 parts of silicone grease, 10 parts of silane, the preparation method of the inner layer 1 is: send the silicone resin and aluminum hydroxide to a ball mill for pulverization, smash through a 400-mesh sieve, send to a mixer, add water and stir for 15 minutes, then add po

Embodiment 2

[0024] Such as figure 1 As shown, a multi-layer co-extruded high-temperature cooking high-barrier film. The barrier film includes an inner layer 1, a barrier layer 2 and an outer layer 3. The inner layer 1 includes PA layer 11 and PP layer 12, PA layer 11 and The PP layer 12 is rolled through the adhesive layer 41 to obtain the inner layer 1. The PA layer 11 in the inner layer 1 is composed of the following components by weight: 60 parts of silicone resin, 20 parts of aluminum hydroxide, and carbonic acid 7 parts of potassium, 2 parts of XC-99-B5654 silicone flame retardant, 0.4 parts of polycaprolactam, PP layer 12 is composed of the following components by weight: 115 parts of chlorinated modified polypropylene, 17 parts of silicone grease, 13 parts of silane and inner layer 1 are prepared as follows: send 60 parts of silicone resin and 20 parts of aluminum hydroxide to a ball mill for pulverization, smash through a 400 mesh sieve, send to a mixer, add water and stir for 15 minut

Embodiment 3

[0026] Such as figure 1 As shown, a multi-layer co-extruded high-temperature cooking high-barrier film. The barrier film includes an inner layer 1, a barrier layer 2 and an outer layer 3. The inner layer 1 includes PA layer 11 and PP layer 12, PA layer 11 and The PP layer 12 is rolled through the adhesive layer 41 to obtain the inner layer 1. The PA layer 11 in the inner layer 1 is composed of the following components by weight: 70 parts of silicone resin, 30 parts of aluminum hydroxide, and carbonic acid 9 parts of potassium, 3 parts of XC-99-B5654 silicone flame retardant, 0.5 parts of polycaprolactam, PP layer 12 is composed of the following components by weight: 130 parts of chlorinated modified polypropylene, 20 parts of silicone grease, 15 parts of silane, the preparation method of inner layer 1 is: send silicone resin 70 and aluminum hydroxide 30 to a ball mill for pulverization, smash through a 400-mesh sieve, send to a mixer, add water and stir for 15 minutes, then add pot

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap