Top cover stamping die

A technology for stamping parts and top cover, applied in the field of top cover stamping parts mold, can solve the problems of quality overflow, cross operation, personnel scratches, etc., and achieve the effect of reasonable structure setting and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] With reference to the drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments.

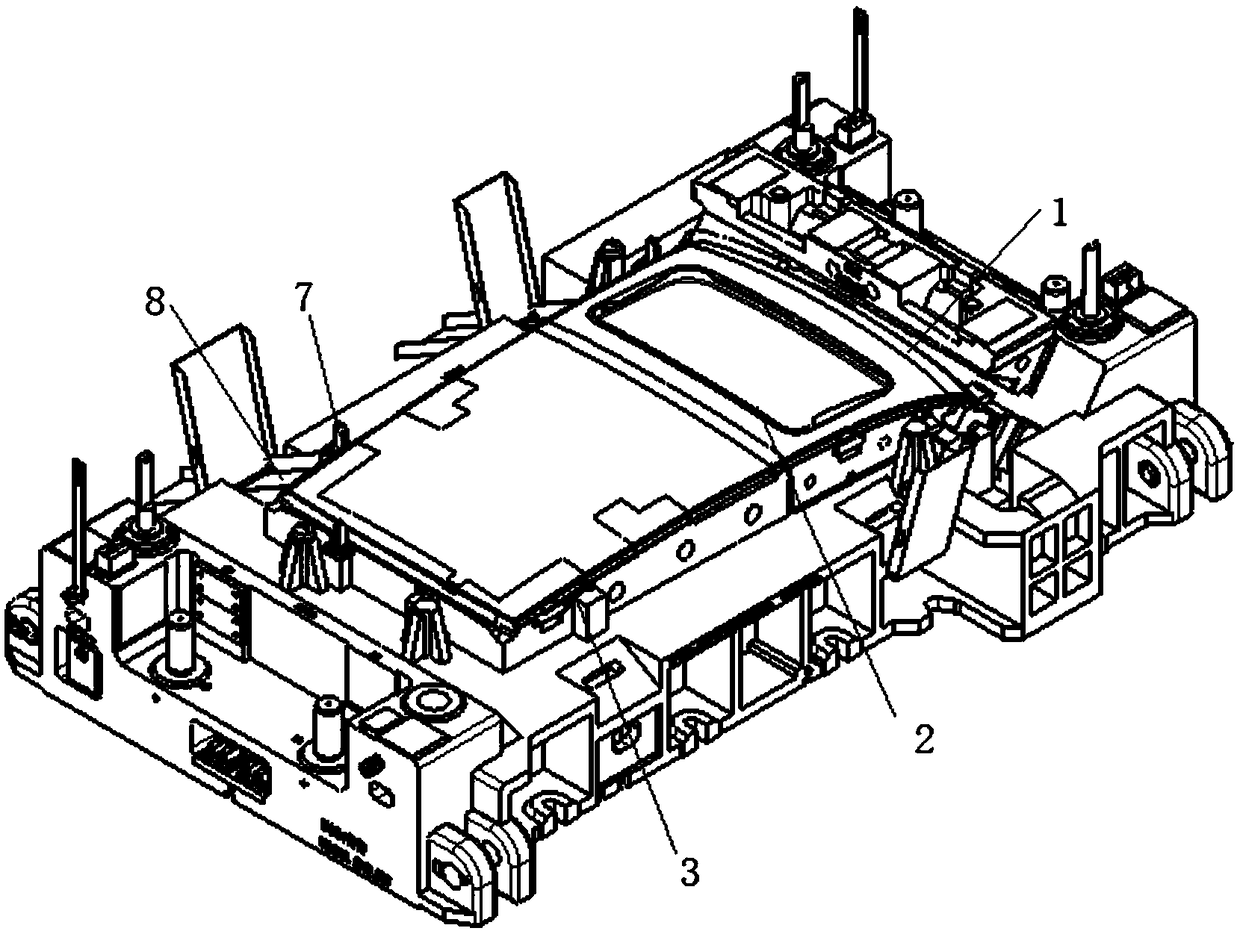

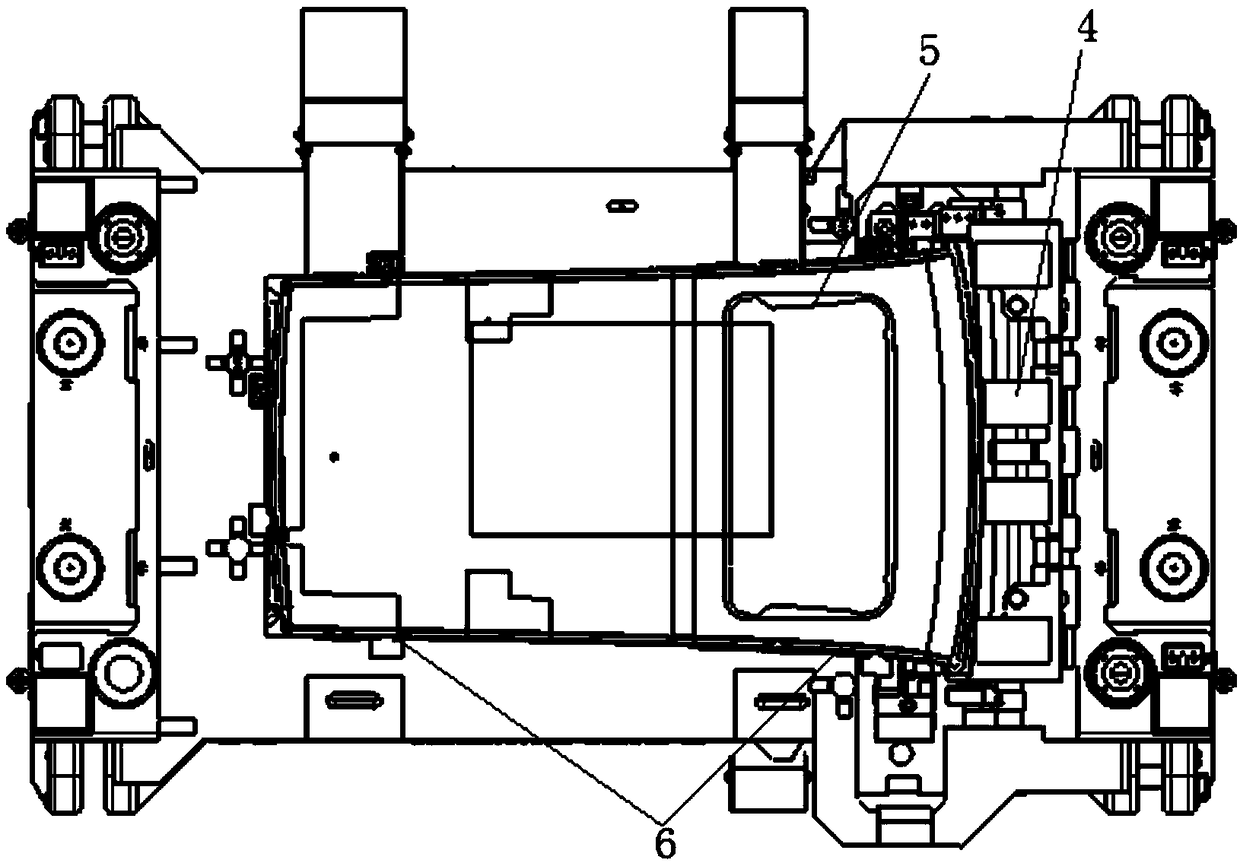

[0018] This invention’s top cover stamping die, such as figure 1 , 2 As shown, it includes a matching upper mold and a lower mold. The front ends of the upper and lower molds are provided with an oblique wedge structure that cooperates to complete the front end of the top cover. The rear of the oblique wedge structure is provided with a skylight flanging mechanism. The lower die is also provided with a punching mechanism corresponding to the punching of the top cover. The die of the top cover stamping part of the present invention combines the original op40 punching, oblique wedge shaping process and op50 flanging process into a sequence mold to meet the process requirements, realize the oblique wedge shaping, punching, and flanging processes, save production costs and improve Work efficiency.

[0019] In the pre

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap