Automatic saw cutting device for aluminum alloy semi-solid die-casting products

A sawing device and semi-solid technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high cost and low efficiency, improve production efficiency, reduce production cost, and reduce multiple handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

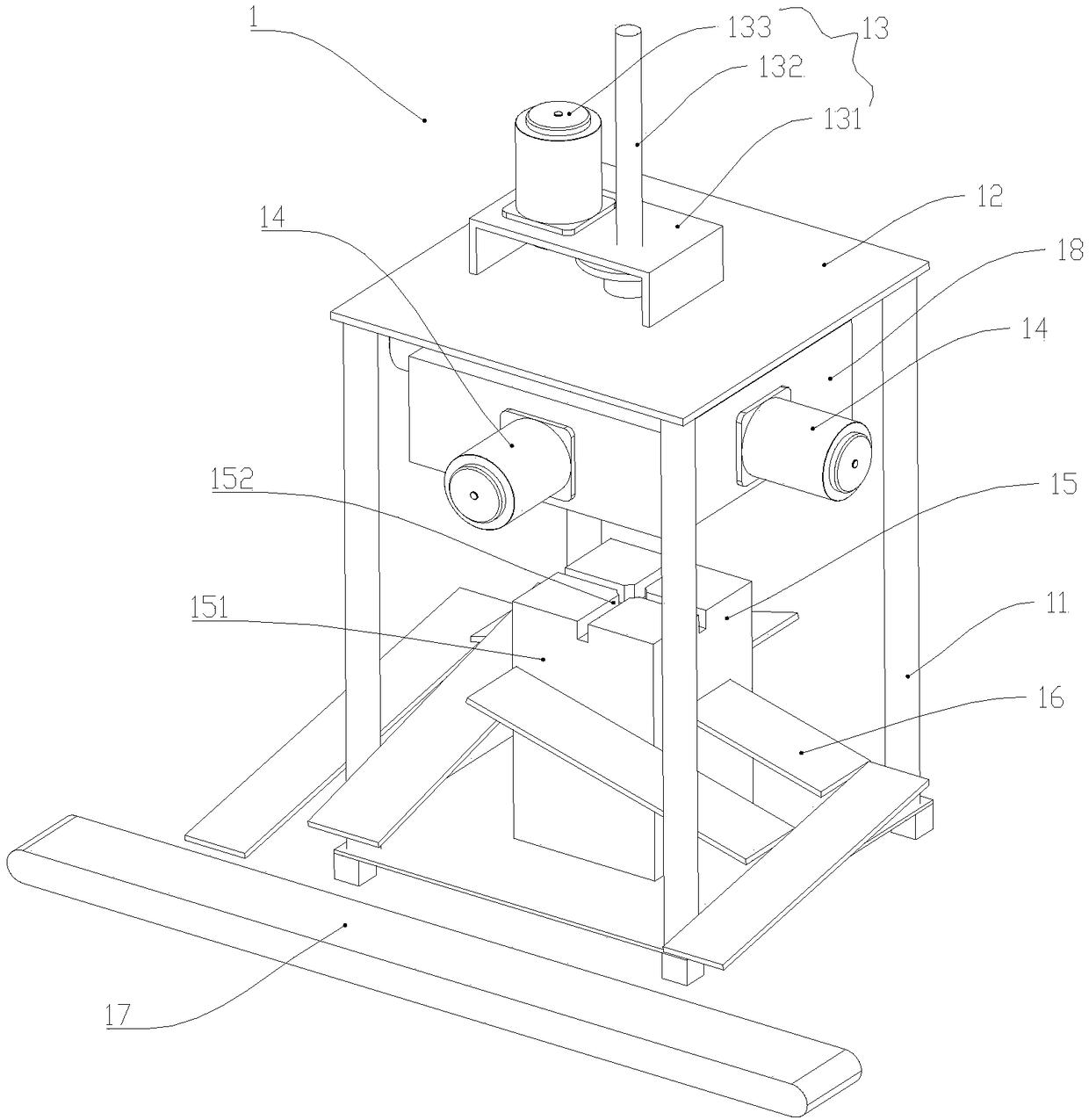

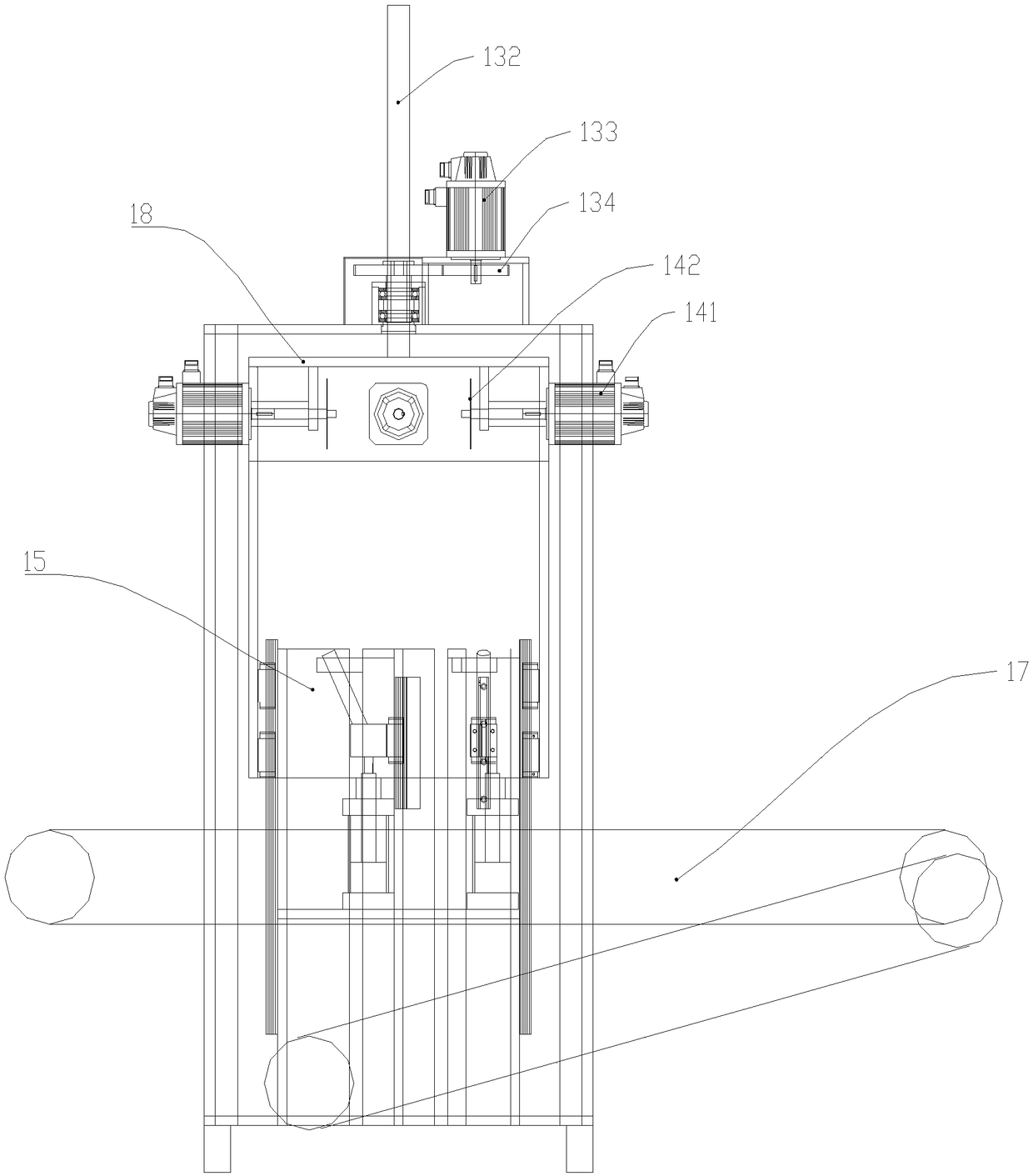

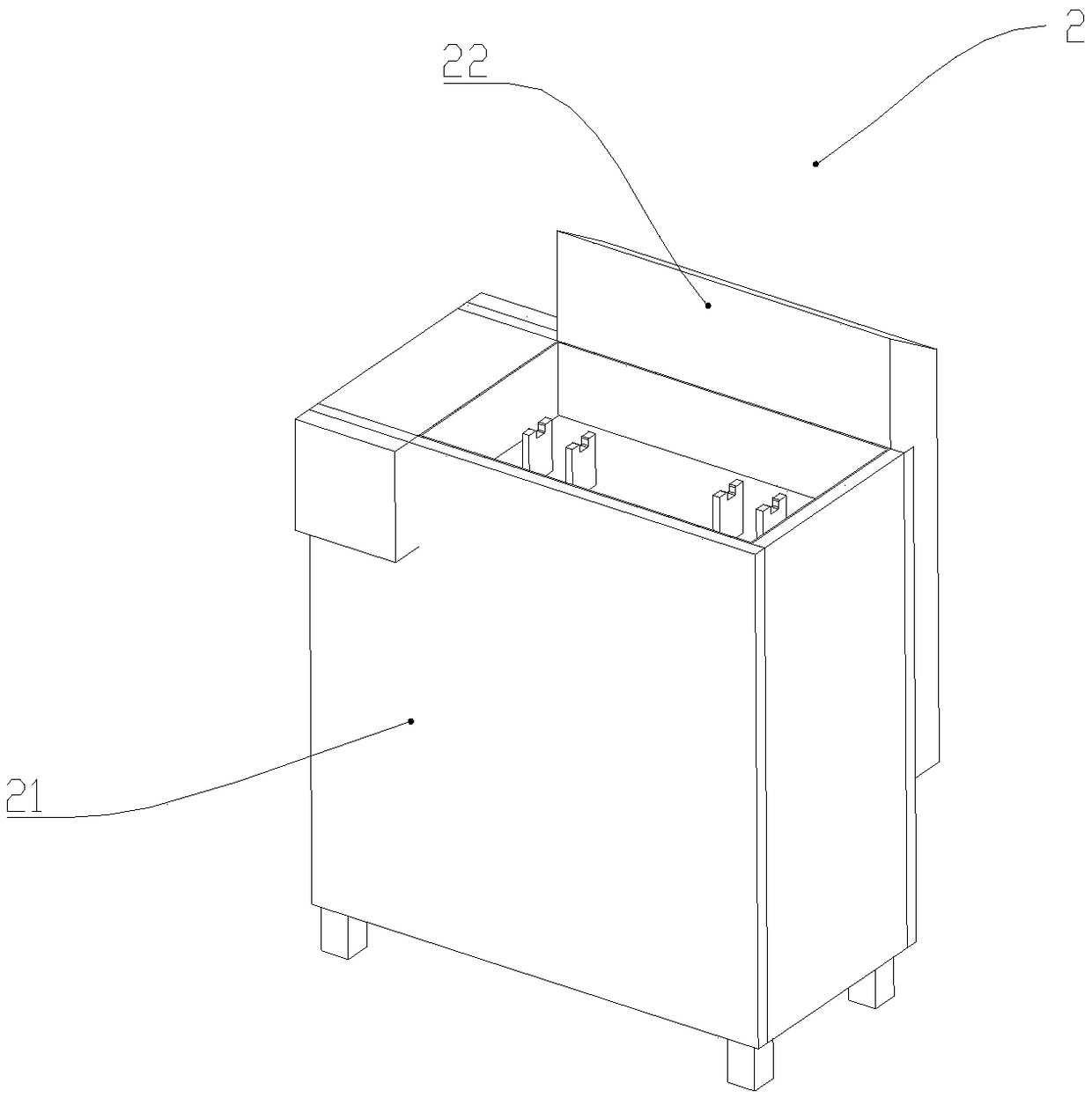

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

[0022] It should be understood that when used in this specification and the appended claims, the terms "including" and "including" indicate the existence of the described features, wholes, steps, operations, elements and / or components, but do not exclude one or The existence or addition of multiple other features, wholes, steps, operations, elements, components, and / or collections thereof.

[0023] It should also be understood that the terms used in thi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap