Environment-friendly antique floor tile and production process thereof

A production process and environmental protection technology, applied in the direction of floor, building, building structure, etc., can solve the problems of complex production process, damage and waste of gold bricks, and achieve rich design aesthetics, easy slicing, and convenient transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0043] Example 1

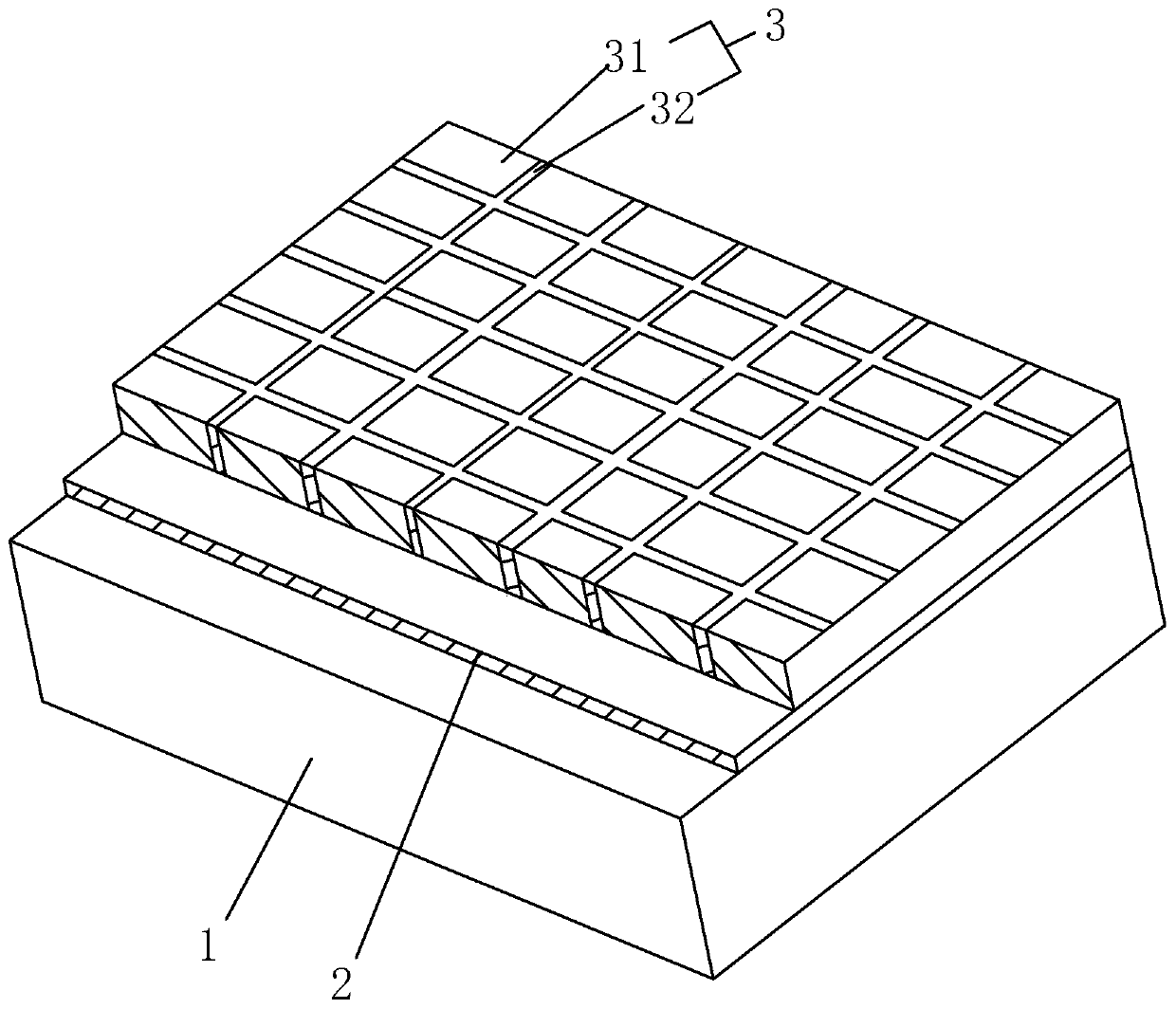

[0044] Environmentally friendly retro floor tiles, such as figure 1 As shown, it includes a base layer 1 and a gold brick decoration layer 3, and an adhesive layer 2 is bonded between the gold brick decoration layer 3 and the base layer 1. The gold brick decoration layer 3 is composed of a number of decorative units 31.

[0045] Combining the gold brick material with the ordinary base layer 1 not only realizes the full utilization of the discarded gold bricks, but also obtains a new type of environmentally friendly floor tiles, which enriches the types of floor tiles. The high hardness of the brick material is beneficial to increase the structural strength of the floor brick; the water permeability of the brick material is excellent, and the floor brick is used on the ground, and the ground is not easy to have water; and the surface of the brick material is frosted, which is not easy to slip. The gold brick decoration layer 3 is composed of several decoration units

Example Embodiment

[0051] Example 2

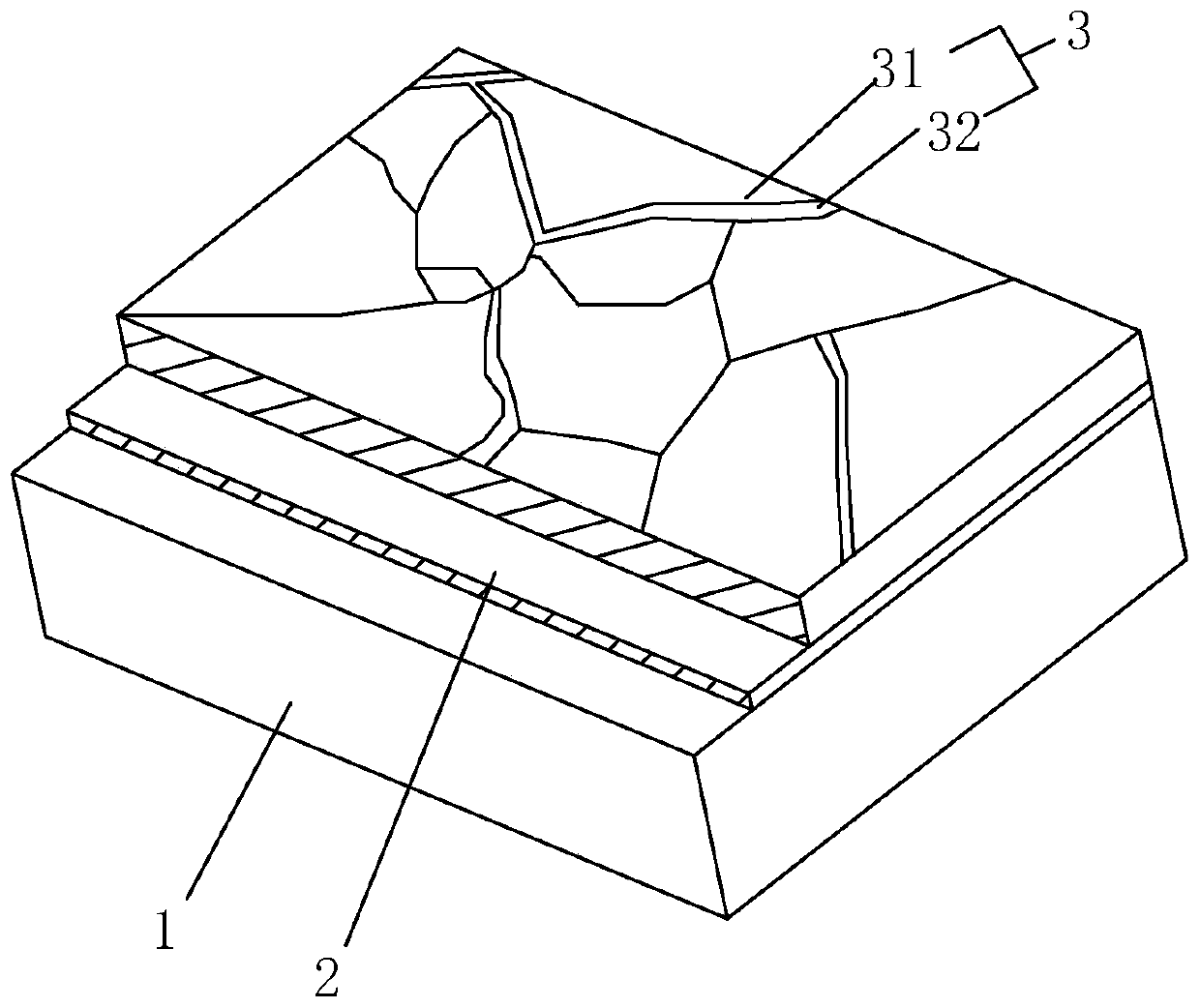

[0052] Environmentally friendly retro floor tiles, the difference between embodiment 2 and embodiment 1 is that the decoration unit 31 is arranged in an irregular shape, which is formed by breaking the gold bricks and then assembled. The surface area of the adjacent decoration unit 31 away from the base layer 1 is different. Equal, so that the surface of the floor tiles presents a combination of multiple shapes and has a more design sense.

[0053] The production process of environmentally friendly retro floor tiles includes the following steps:

[0054] Step 1: Cut the recycled gold bricks into thin slices;

[0055] Step 2: Break the gold brick sheet in step 1 to form multiple decorative units;

[0056] Step three, splicing and assemble the decoration units in step two;

[0057] Step 4: Add a caulking agent to the gaps between adjacent decoration units. After the caulking agent dries, a decorative layer of gold bricks is formed, and the decorative layer of gold bricks

Example Embodiment

[0062] Example 9

[0063] The production process of environmentally-friendly retro floor tiles. The difference between Example 9 and Example 4 is that in step 4, after the medium caulking agent has dried up, the gold brick decorative layer is cut into 0.5-1.5cm thin slices; After the decorative layer is split, the joints are filled again with a caulking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap