High-strength material for manufacturing sanitary wares and manufacturing method thereof

A hygienic, high-strength technology, used in the manufacture of high-strength materials for sanitary ware and its manufacturing field, can solve the problems of high energy consumption, low compressive strength, easy cracking, etc., to change the low-end and rough positioning, increase resistance Tensile strength, waterproof performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of bathtub

[0036] (1) Weigh the ingredients according to the following weights; 100 parts of cement, 130 parts of river sand, 35 parts of calcium carbonate powder, 19 parts of silica fume, 3 parts of PVA fiber, 5 parts of water reducing agent, 18 parts of water;

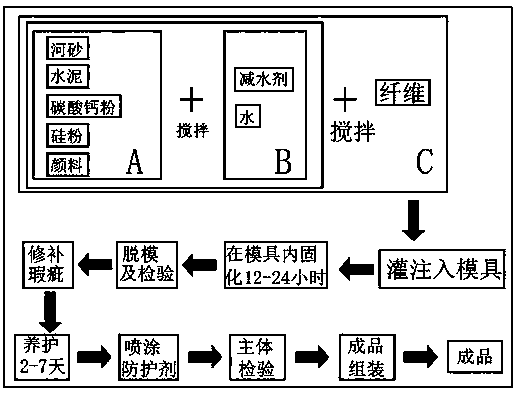

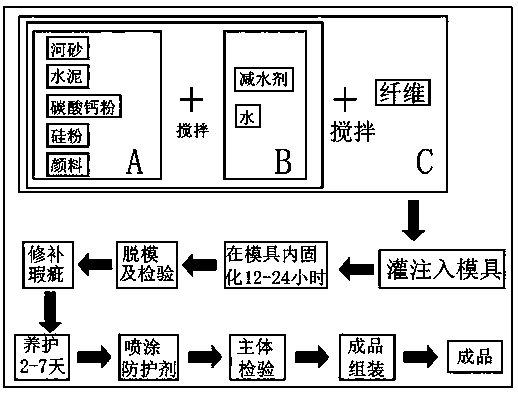

[0037] (2) Wash the river sand and screen it; add cement, calcium carbonate powder, and silica powder and mix evenly to obtain a solid mixture A;

[0038] (3) Add high-performance water-reducing agent to water and mix evenly to obtain liquid mixture B;

[0039] (4) Add liquid mixture B to solid mixture A and mix for about 3-8 minutes to obtain cement mortar mixture C;

[0040] (5) Add fiber to cement mortar mixture C, and mix for 3-8 minutes. Obtain fiber cement mortar mixture D;

[0041] (6) Inject the fiber cement mortar mixture D into the glass fiber reinforced plastic or metal mold of the product, where the glass fiber reinforced plastic or metal mold is placed on the vibration table, and the mo

Embodiment 2

[0048] Example 2 Preparation of shower tray

[0049] (1) Weigh the components according to the following weights; 100 parts of cement, 140 parts of river sand, 30 parts of calcium carbonate powder, 12 parts of silica fume, 7 parts of glass fiber, 5 parts of water reducing agent, 20 parts of water;

[0050] (2) Wash the river sand and screen it; add cement, calcium carbonate powder, and silica powder and mix evenly to obtain a solid mixture A;

[0051] (3) Add high-performance water-reducing agent to water and mix evenly to obtain liquid mixture B;

[0052] (4) Add liquid mixture B to solid mixture A and mix for about 3-8 minutes to obtain cement mortar mixture C;

[0053] (5) Add fiber to cement mortar mixture C, and mix for 3-8 minutes. Obtain fiber cement mortar mixture D;

[0054] (6) Inject the fiber cement mortar mixture D into the glass fiber reinforced plastic or metal mold of the product, where the glass fiber reinforced plastic or metal mold is placed on the vibration table, and t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap