Preparation method of SnSe nanosheet

A technology of tin selenide and nanosheets, which is applied in nanotechnology, ion implantation plating, coating and other directions, can solve the problems of inability to obtain tin selenide, etc., and achieves no protective gas and carrier gas, less environmental pollution, and lower environmental pollution. High surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 of the present application provides the first preparation method of tin selenide nanosheets, the specific steps are as follows:

[0034] The tin selenide powder (its purity is 99.999%) of 0.197g is weighed and then poured into a crucible as an evaporation source, and a silicon wafer is placed at 2.5 cm above the evaporation source as a substrate. Vacuum up to 5×10 -5 At Pa, the evaporation source was evenly heated to 470° C., kept for 5 minutes for vacuum coating, and finally black deposits were obtained on the substrate to obtain tin selenide nanosheets.

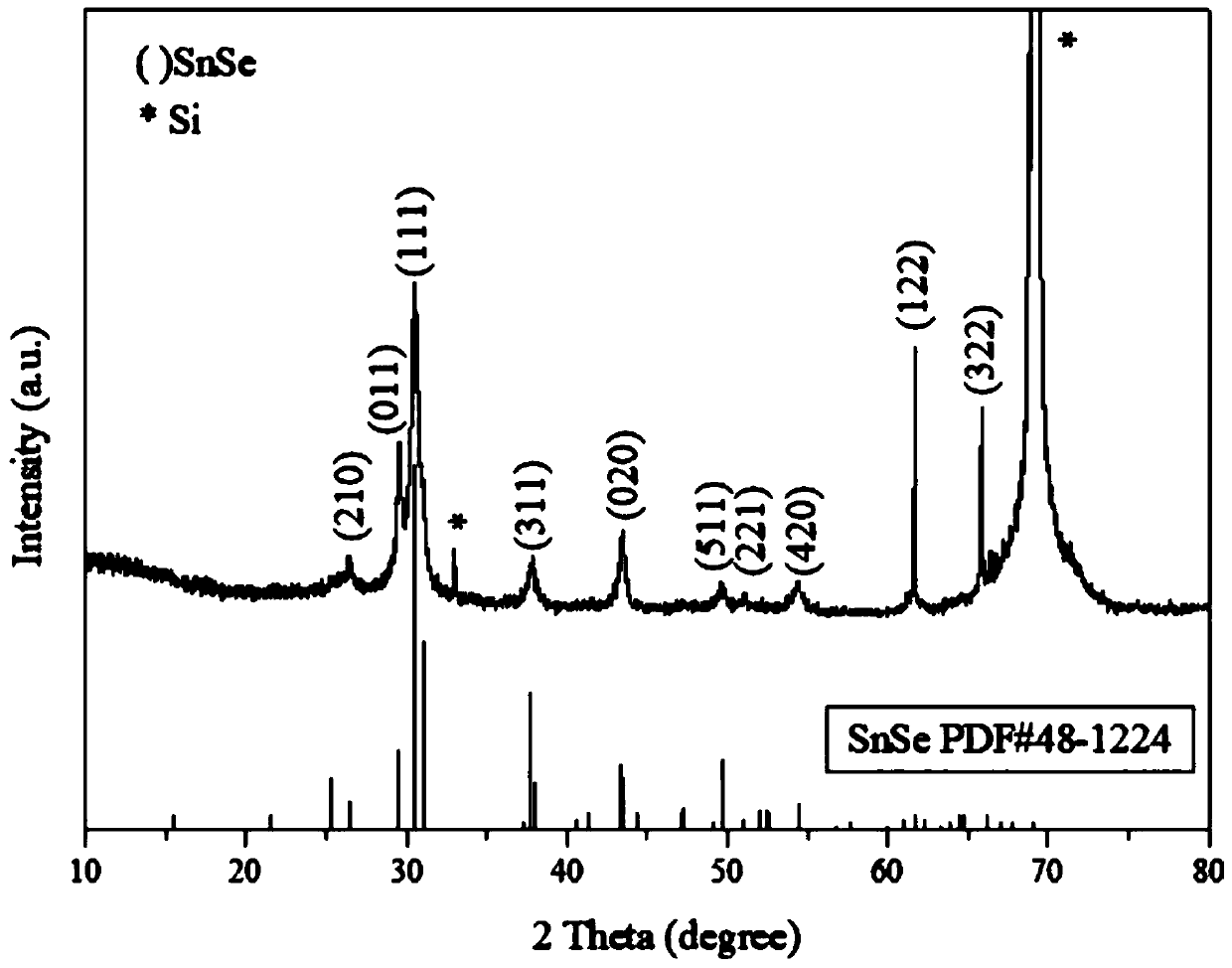

[0035] Carry out X-ray diffraction detection to the tin selenide nanosheet that the application embodiment 1 makes, as figure 1 As shown, it can be seen that the tin selenide nanosheets are orthorhombic SnSe, and its diffraction peaks are consistent with the PDF#48-1224 standard card. In addition, there are diffraction peaks from Si, which come from the Si sheet of the substrate.

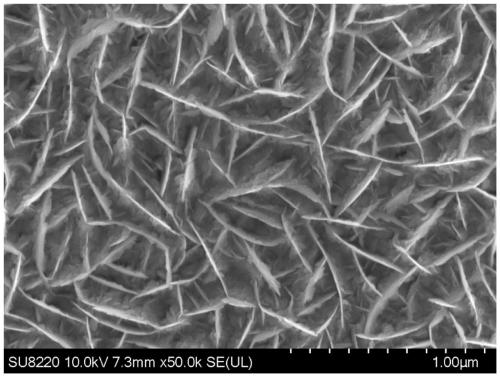

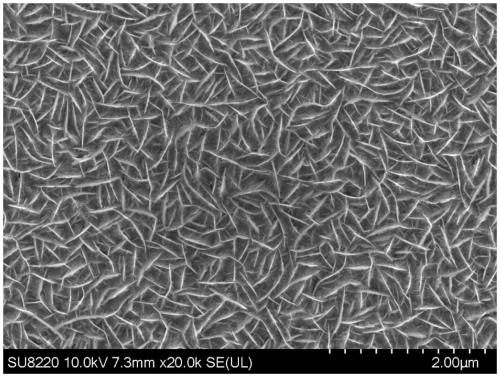

[0036] Scanning electron m

Embodiment 2

[0039] Example 2 of the present application provides a second method for preparing tin selenide nanosheets, the specific steps are as follows:

[0040]Weigh 0.197g of SnSe powder (99.999%) and pour it into a crucible as an evaporation source. Place an ITO conductive glass as a substrate at 2.4cm above the evaporation source. When the vacuum degree in the vacuum thermal evaporation coating machine reaches 2×10 -5 At Pa, the evaporation source was evenly heated to 460° C. and kept for 6 minutes, and finally tin selenide nanosheets with black deposits were obtained on the substrate.

[0041] The X-ray diffraction results, scanning electron microscope results and element distribution detection results of the tin selenide nanosheets in this example are similar to those of Example 1.

Embodiment 3

[0043] Example 3 of the present application provides a third preparation method of tin selenide nanosheets, the specific steps are as follows:

[0044] Weigh 0.197g of SnSe powder (99.999%) and pour it into a crucible as an evaporation source. Place a molybdenum foil as a substrate at 2.6cm above the evaporation source. When the vacuum degree in the vacuum thermal evaporation coating machine reaches 3.5×10 -5 At Pa, the evaporation source is evenly heated to 480° C. and kept for about 5 minutes, and finally tin selenide nanosheets with black deposits are obtained on the substrate.

[0045] The X-ray diffraction results, scanning electron microscope results and element distribution detection results of the tin selenide nanosheets in this example are similar to those of Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap