Aluminum electrolytic capacitor based on multi-layer winding paper design

A technology of aluminum electrolytic capacitors and capacitors, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of defective products, difficult impregnation and high cost, etc., and achieve the effects of long product life, thorough impregnation and absorption, and easy manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

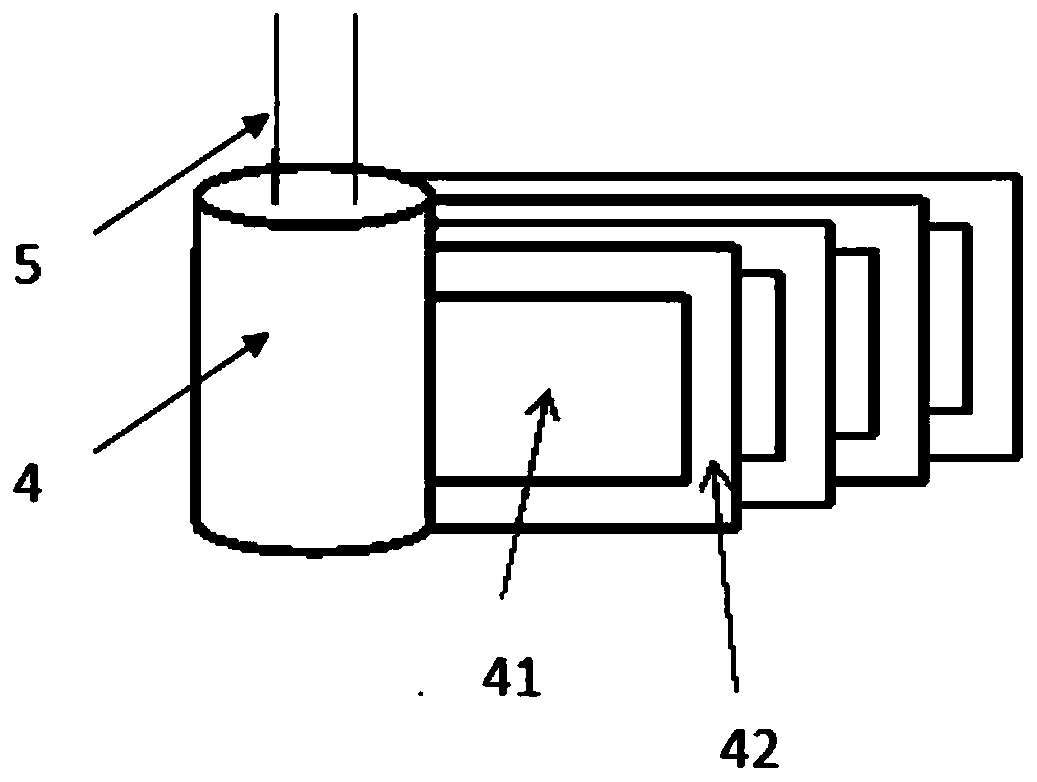

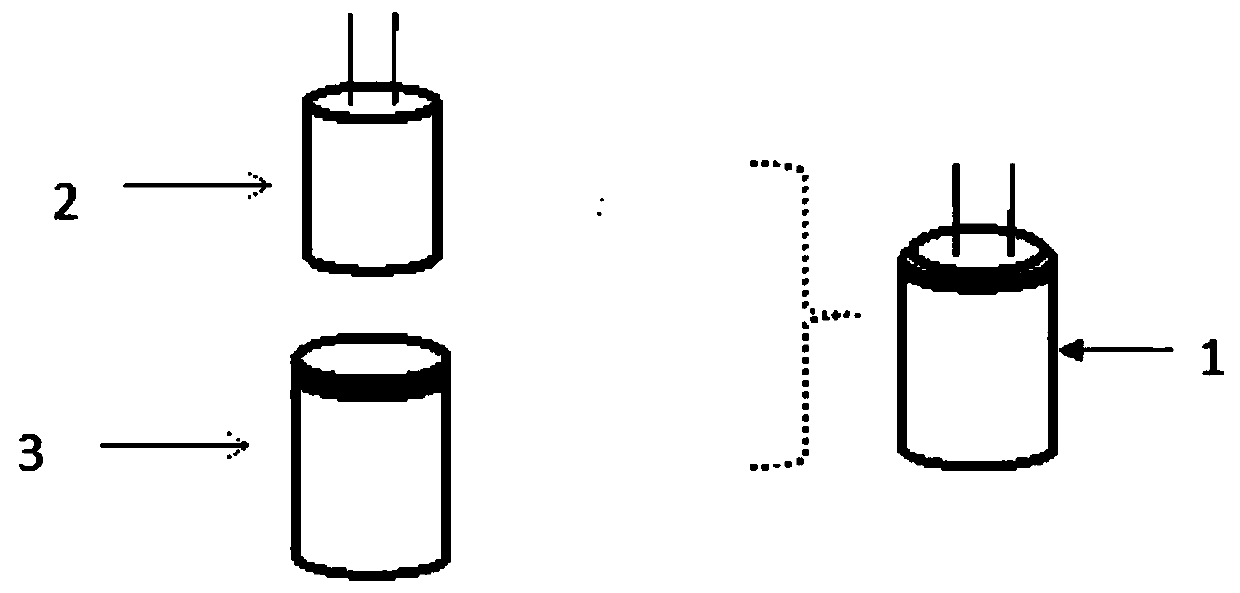

[0019] Such as figure 1 and figure 2 As shown, in this embodiment, the aluminum electrolytic capacitor designed based on multi-layer rolled paper includes a capacitor body 1, and the capacitor body 1 is composed of an element 2 and an aluminum shell 3, and the element 2 is arranged on the aluminum shell 3 Inside, the element 2 includes no less than three winding layers 4 and guide pins 5 disposed in the winding layers 4 , and the winding layers 4 are formed by winding aluminum foil 41 and electrolytic paper 42 . The capacitor main body 1 is an aluminum electrolytic capacitor with a medium to high voltage or higher.

[0020] The applicant declares that, on the basis of the above-mentioned embodiments, those skilled in the art combine certain steps of the above-mentioned embodiments with the technical solutions in the summary of the invention to produce a new method, which is also one of the scope of the present invention. In order to make the description concise, the present ap

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap