Flue gas waste heat exchange device with dirt accumulation prevention function

A flue gas waste heat and exchange equipment technology, which is applied in the field of flue gas waste heat recovery, can solve problems such as unfavorable maintenance and replacement, dirt cleaning, bulky heat exchanger, and complicated spiral structure, so as to reduce maintenance and use costs and improve economic benefits , Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

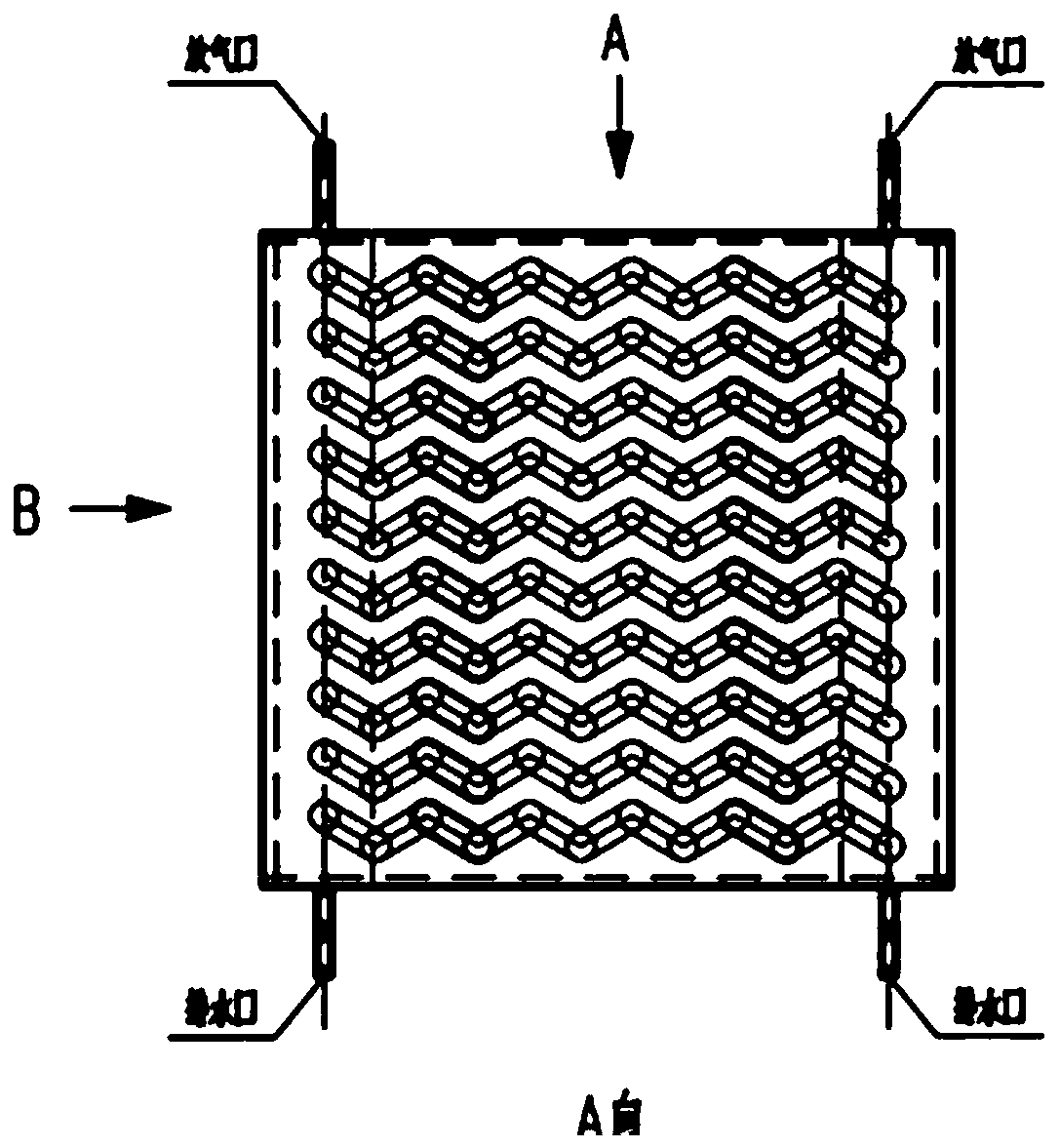

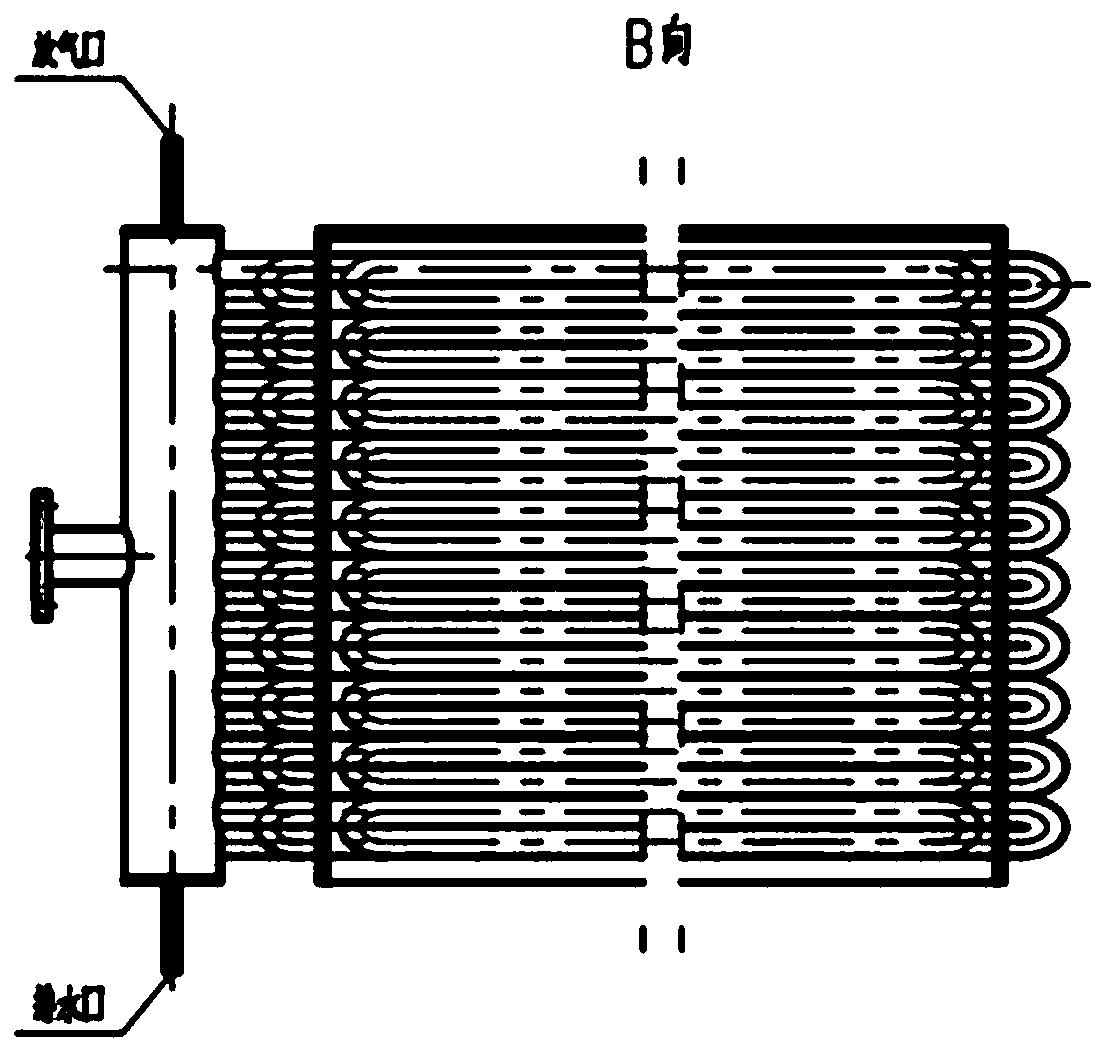

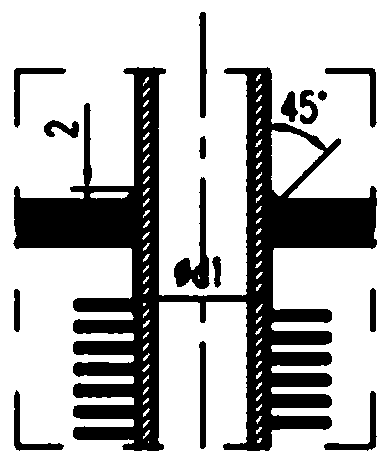

[0015] Figure 4 Middle: 1-box, 2-inlet header, 3-outlet header, 4-U-shaped spiral finned tube, 5-flue gas inlet, 6-flue gas outlet.

[0016] The purpose of the present invention is to provide a new waste heat exchange device with the function of self-maintaining cleanliness and avoiding the accumulation of dirt, aiming at the problem of fouling of common industrial flue gas waste heat recovery devices.

[0017] A flue gas waste heat exchange device with the function of preventing dirt accumulation, including a box body, a U-shaped spiral finned tube, an inlet header, an outlet header, a flue gas outlet, and a flue gas inlet. The U-shaped spiral finned tube is connected to In the inlet header and the outlet header, the inlet header is equipped with an air vent and a drain, and the outlet header is equipped with an air vent and a drain, and the inside of the box includes

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap