Motor vehicle and power converter device for a motor vehicle

A technology of motor vehicles and converters, which is applied in the direction of power devices, electromechanical devices, electric power devices, etc., can solve the problems of easy leaking seals and large structural space of inverters, and achieve the goal of saving structural space and safer operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

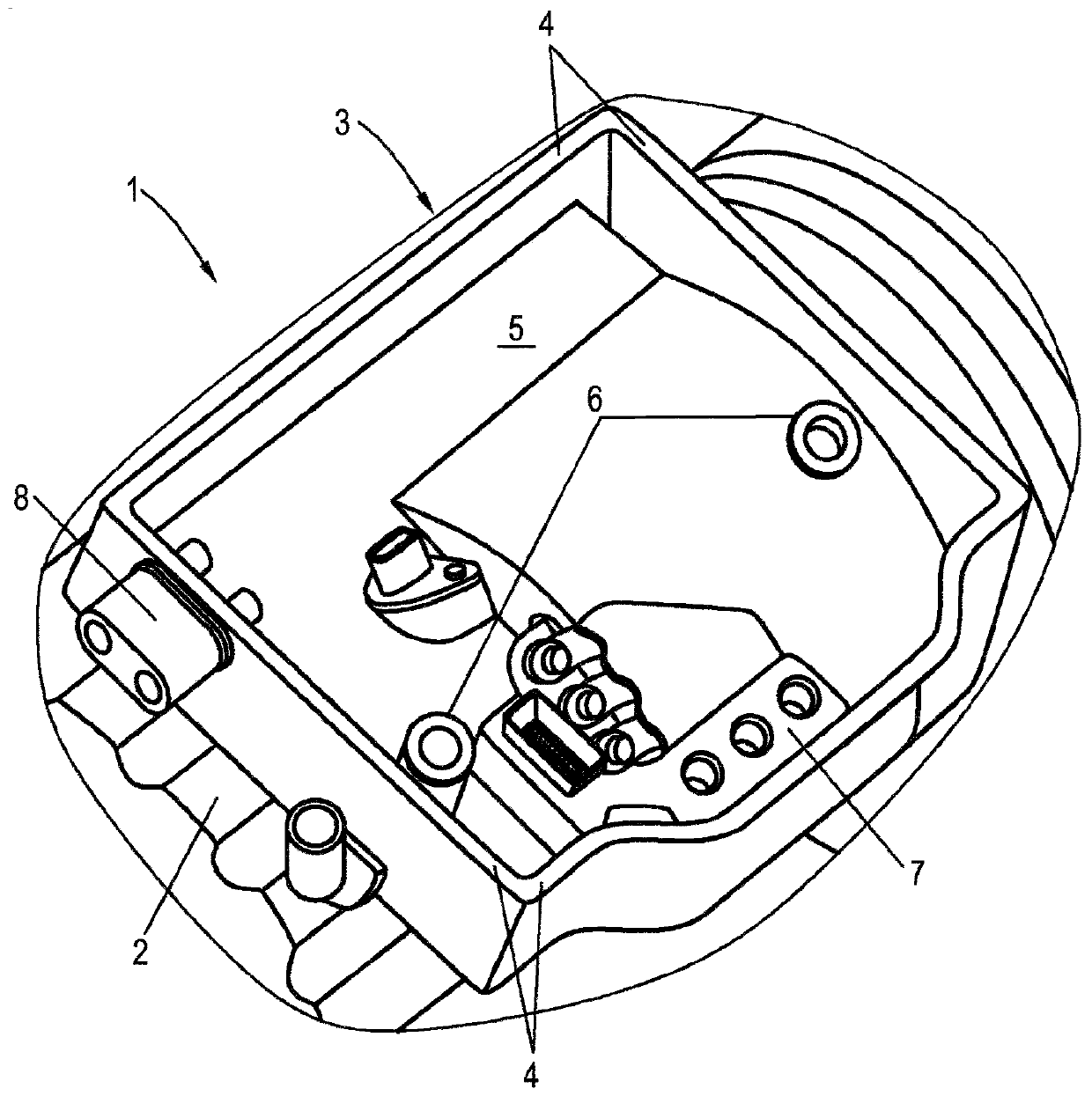

[0031] figure 1 A detailed view of the electric machine 1 is shown, the electric machine housing 2 being partly visible.

[0032] The motor housing 2 has a frame-like or groove-like section 3 with walls 4 which delimit a receiving area 5 . A coolant connection 6 is provided within the receiving area 5 for the introduction and removal of coolant for cooling the stator and / or the rotor of the electric machine 1 . Furthermore, a connection device 7 is provided within the receiving area 5 for supplying the electric machine 1 with a three-phase AC voltage and a DC voltage provided by a low-voltage battery, for example 12 volts. Furthermore, a direct voltage connection 8 is integrated in the wall 4 for supplying a direct voltage from a high-voltage battery to be converted into an alternating voltage.

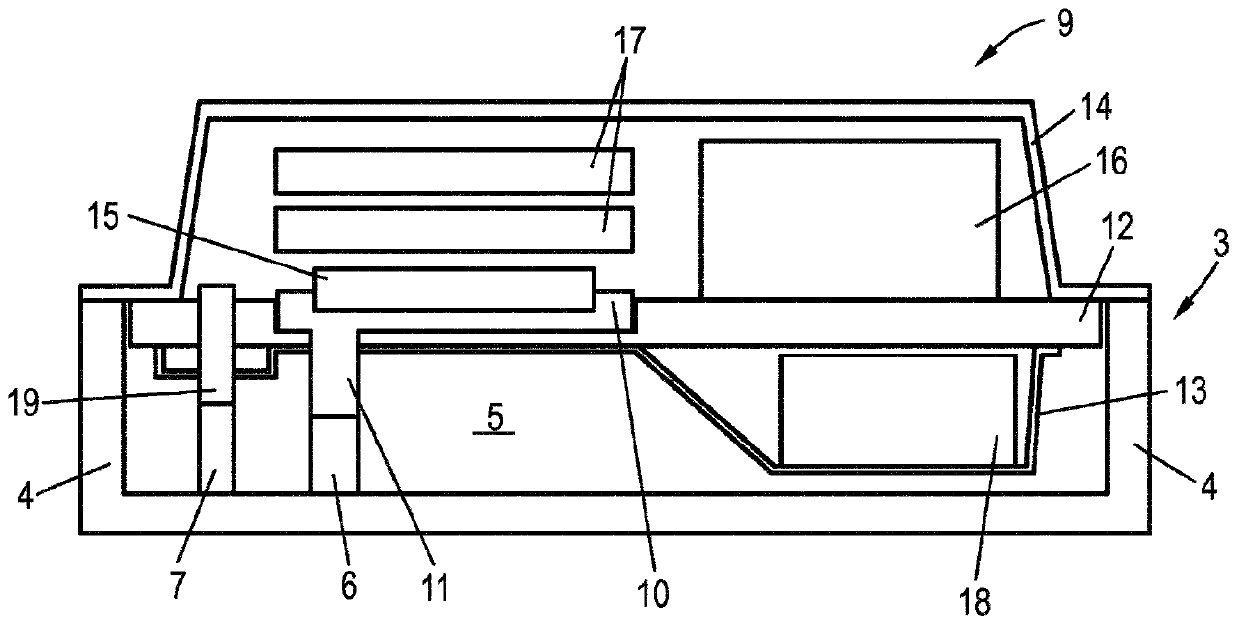

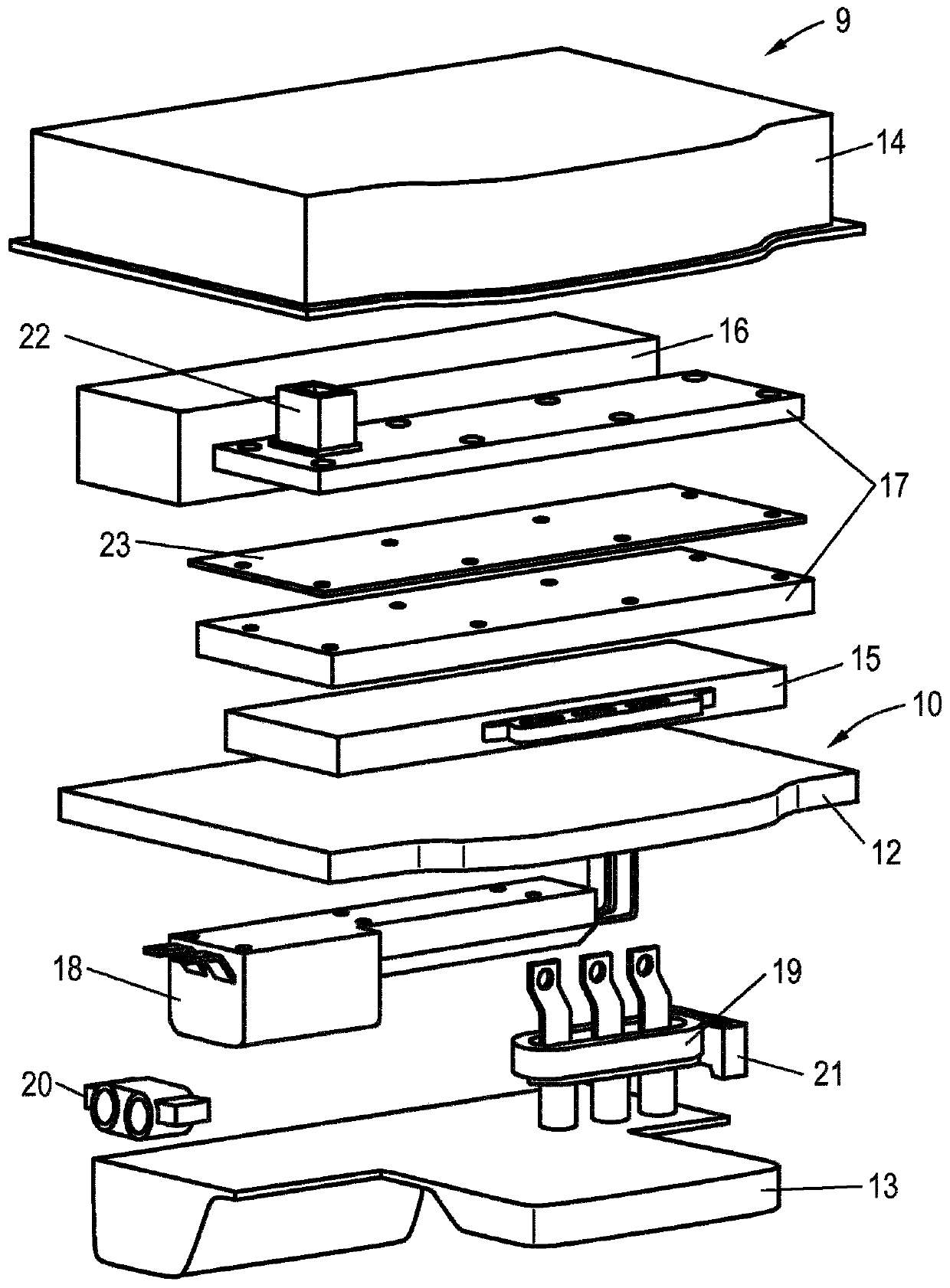

[0033] figure 1 The open side of the receiving area 5 in the installed state additionally passes through the converter device 9 (see Figure 2 to Figure 5 ), the converter device i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap