Hydrophilic breathable medical hot melt pressure sensitive adhesive matrix and preparation method thereof

A melting pressure-sensitive adhesive matrix and air permeability technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of insufficient hydrophilicity and air permeability, poor air permeability and perspiration effect, and types and limited drug content, etc., to achieve good hydrophilicity and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

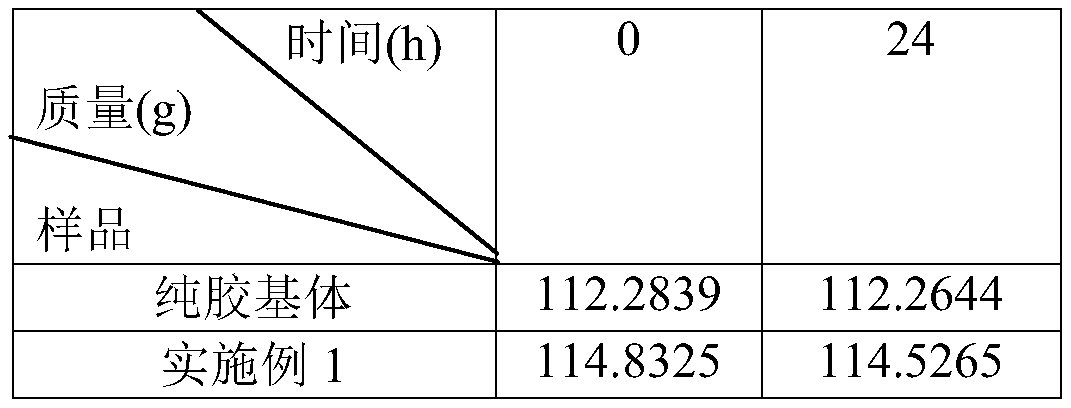

Embodiment 1

[0021] (1) Formulation:

[0022] 70 parts of polyisobutylene (polyisobutylene N50), 30 parts of methyl vinyl silicone rubber, 10 parts of plasticizer (paraffin oil), 10 parts of silicate clay (sepiolite); among them, sepiolite has been subjected to the following Impurity removal treatment: take sepiolite and place it in hydrochloric acid with a concentration of 1mol / L, stir and soak it at 70°C for 2 hours, take it out, wash it with water until it is neutral, and dry it.

[0023] (2) Preparation method:

[0024] ① Weigh each component according to the formula and set aside;

[0025] ② Soak polyisobutylene in plasticizer until it swells;

[0026] ③ Put the swollen polyisobutylene and methyl vinyl silicone rubber in a rubber internal mixer, and knead at a speed of 50r / min at 180°C for 20min; then add silicate clay, and mix at 180°C at a speed of 20r / min The mixing speed is 40min to obtain the hydrophilic air-permeable medical hot-melt pressure-sensitive adhesive matrix. Th

Embodiment 2

[0044] (1) Formulation:

[0045] 75 parts of polyisobutylene (polyisobutylene N50), 25 parts of methyl vinyl silicone rubber, 15 parts of plasticizer (naphthenic oil), 5 parts of silicate clay (illite); among them, illite has undergone the following removal in advance Miscellaneous treatment: take illite and place it in hydrochloric acid with a concentration of 2mol / L, stir and soak it at 60°C for 2 hours, take it out, wash it with water until it is neutral, and dry it.

[0046] (2) Preparation method:

[0047] With embodiment 1.

Embodiment 3

[0049] (1) Formulation:

[0050] Polyisobutylene (polyisobutylene N50) 65 parts, methyl vinyl silicone rubber 35 parts, plasticizer (composed of wax oil and naphthenic oil in a weight ratio of 1:1) 10 parts, silicate clay (made of montmorillonite soil and kaolin at a weight ratio of 1:1) 8 parts; wherein, montmorillonite and kaolin have been subjected to the following impurity removal treatment in advance: take montmorillonite and kaolin respectively with sulfuric acid with a concentration of 1mol / L at 60 ° C Stir and soak for 2 hours, take it out, wash with water until neutral, and dry.

[0051] (2) Preparation method:

[0052] With embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap