Double-surface internal pasted jet printing material

A double-sided, material-based technology, applied in the fields of advertising and decoration, can solve problems such as difficult large-scale promotion and use, difficult to guarantee quality, complicated process, etc., and achieve the effects of favorable promotion and use, high production efficiency and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

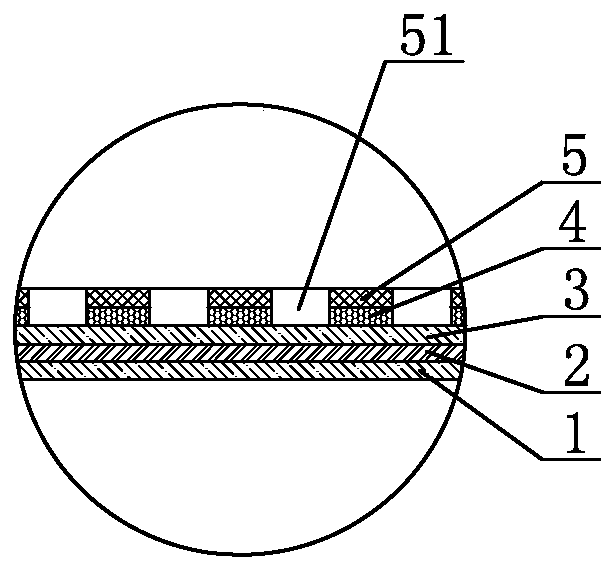

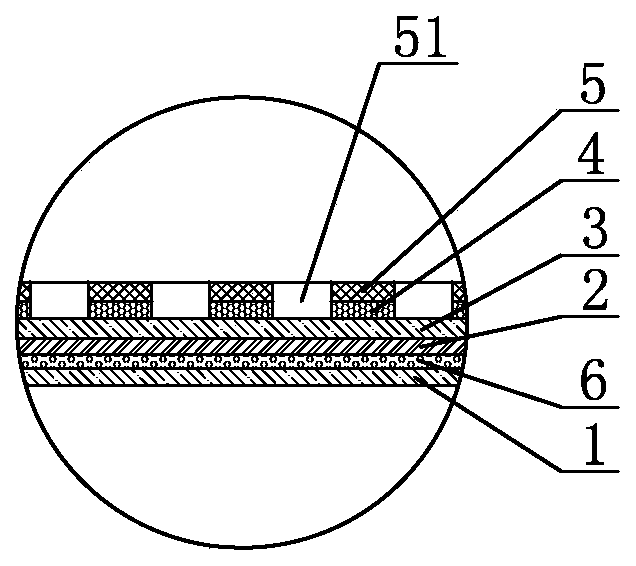

[0030] During production, use PET release film or paper release film as the raw material of the isolation layer, first apply pressure-sensitive adhesive (commonly known as self-adhesive) on the release surface of the isolation layer, the self-adhesive can be transparent or white Wait for different colors, dry, and then stick the temporary release film on the surface of the pressure-sensitive adhesive of the isolation layer, so that the pressure-sensitive adhesive is in a protected state. Then, the isolation layer coated with pressure-sensitive adhesive is placed on a punching machine to punch holes, so that the isolation layer is formed into a porous isolation layer 5 with through holes 51 , and the through holes 51 penetrate through the pressure-sensitive adhesive layer 4 . In this way, after the holes are punched, there is no pressure-sensitive adhesive in the places where the isolation layer has holes. Then, use the white PVC film as the ink-absorbing base material layer 3,...

Embodiment 2

[0032]During production, use PET release film or paper release film as the raw material of the isolation layer, first apply pressure-sensitive adhesive (commonly known as self-adhesive) on the release surface of the isolation layer, the self-adhesive can be transparent or white Wait for different colors, dry, and then stick the temporary release film on the surface of the pressure-sensitive adhesive of the isolation layer, so that the pressure-sensitive adhesive is in a protected state. Then, the isolation layer coated with pressure-sensitive adhesive is placed on a punching machine to punch holes, so that the isolation layer is formed into a porous isolation layer 5 with through holes 51 , and the through holes 51 penetrate through the pressure-sensitive adhesive layer 4 . In this way, after the holes are punched, there is no pressure-sensitive adhesive in the places where the isolation layer has holes. Then, use a white PVC film as the ink-absorbing base layer 3, use a white...

Embodiment 3

[0034] During production, use PET release film or paper release film as the raw material of the isolation layer, first apply pressure-sensitive adhesive (commonly known as self-adhesive) on the release surface of the isolation layer, the self-adhesive can be transparent or white Wait for different colors, dry, and then stick the temporary release film on the surface of the pressure-sensitive adhesive of the isolation layer, so that the pressure-sensitive adhesive is in a protected state. Then, the isolation layer coated with pressure-sensitive adhesive is placed on a punching machine to punch holes, so that the isolation layer is formed into a porous isolation layer 5 with through holes 51 , and the through holes 51 penetrate through the pressure-sensitive adhesive layer 4 . In this way, after the holes are punched, there is no pressure-sensitive adhesive in the places where the isolation layer has holes. Then, use a white PVC film as the ink-absorbing base layer 3, use a whit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap