Catalytic cracking method

A catalytic cracking and catalyst technology, applied in chemical instruments and methods, catalysts, carbon compound catalysts, etc., can solve problems such as unfavorable cracking reactions, large agent-oil ratio, and poor product distribution, and achieve the effect of reducing thermal cracking reactions.

Active Publication Date: 2020-04-03

CHINA PETROLEUM & CHEM CORP +1

View PDF13 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The technical effect that this new technology has compared well before it was invented is improved efficiency during production processes caused by reducing heat damage from reactions between oils at high temperatures without losing their quality or causing other problems such as coking issues.

Problems solved by technology

Technologies described involve improving the efficiency of catalysis in petroleum refining processes involving oxidizing organics (OX) like methyl ethersulfonic acid diesters called dimmers). However, these techniques aim to optimize the performance and utilization rate of the overall catalyst cycle.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

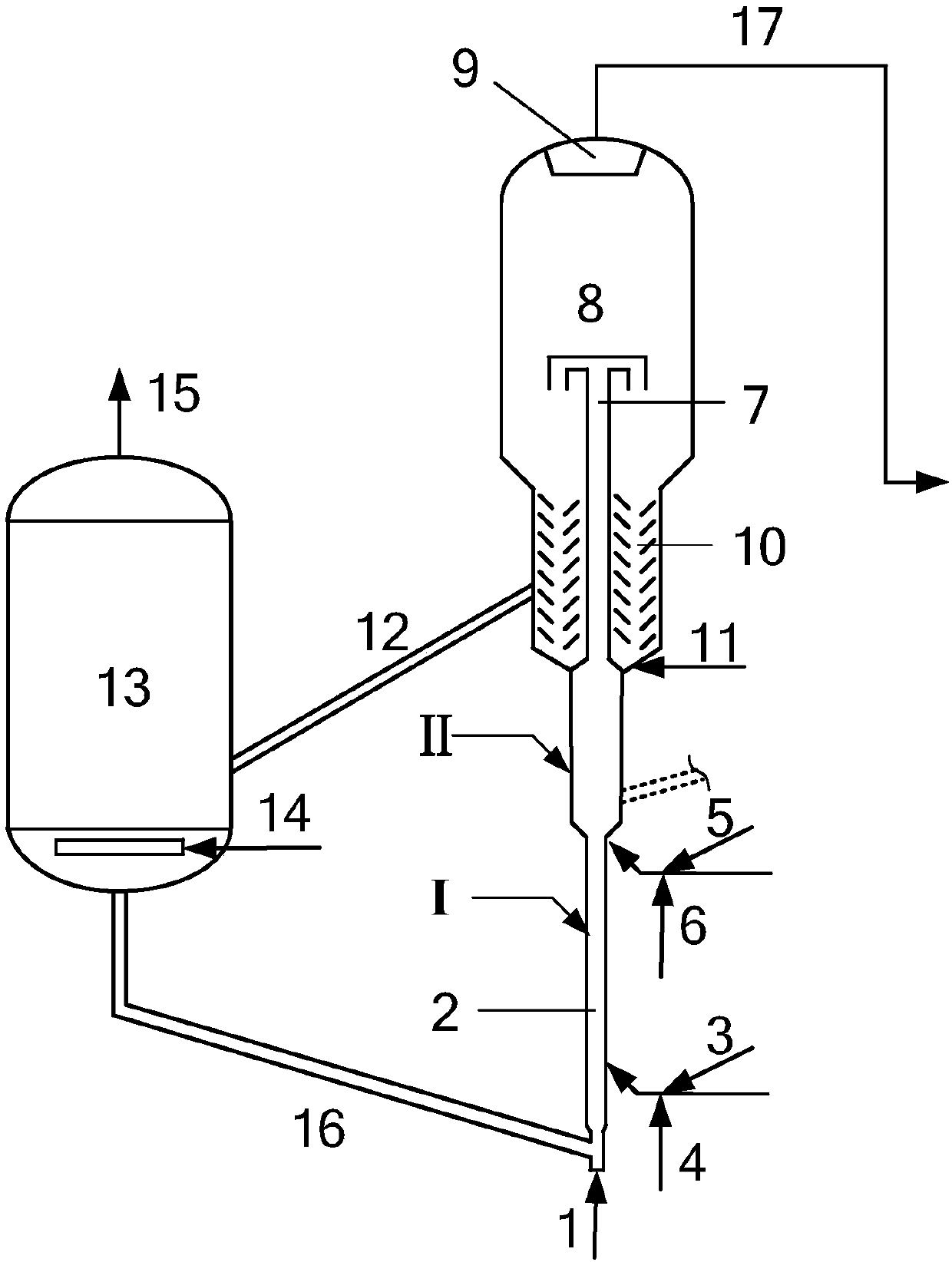

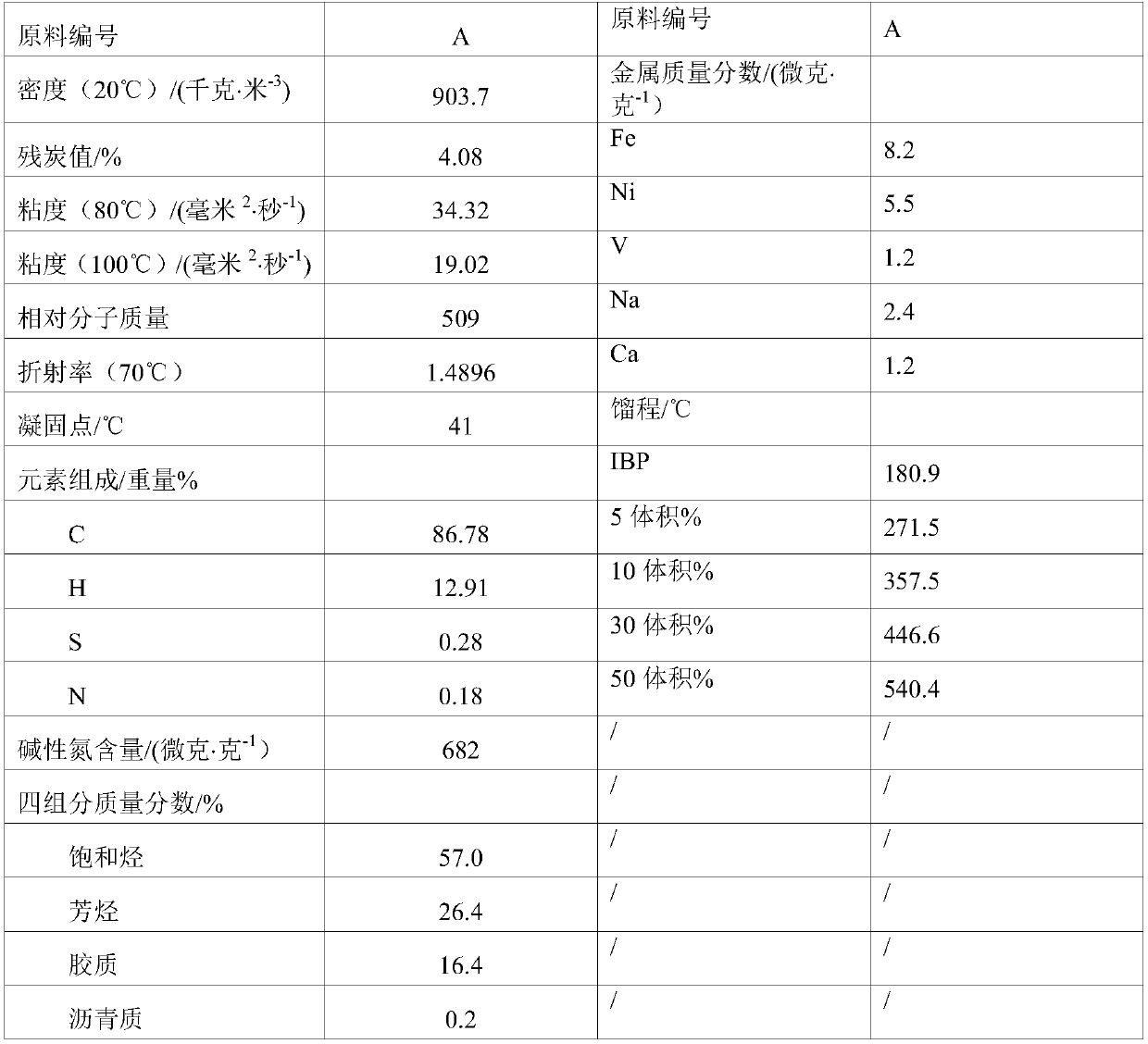

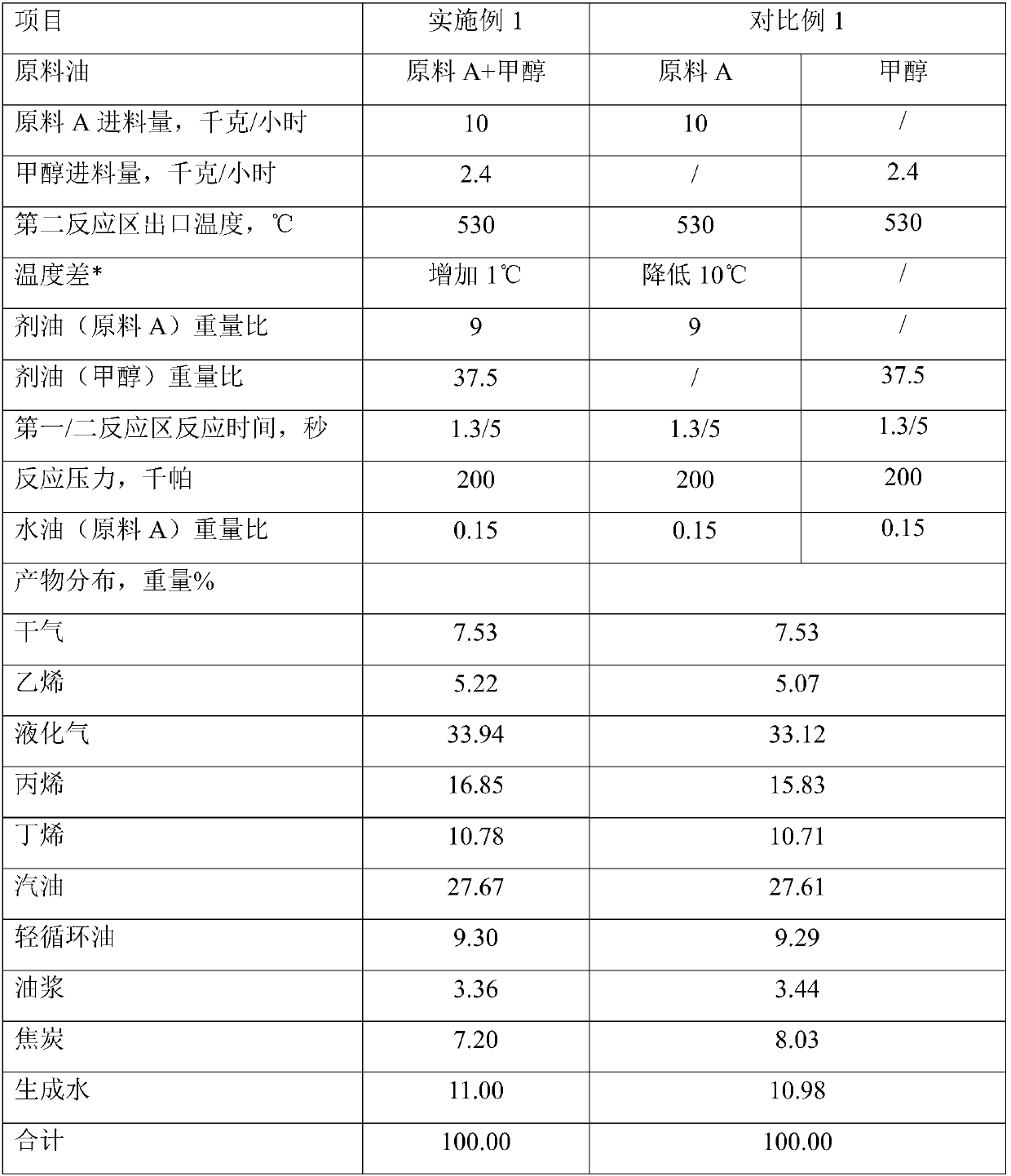

[0066] Embodiment 1 is according to the aforementioned flow process in the specific embodiment figure 1 The medium-sized device shown was performed. The properties of raw material A used are shown in Table 1, and the catalyst used is catalyst A. The preheating temperature of the oxygen-containing compound is 360° C., and the carbon content of the semi-spent catalyst is 0.95% by weight. The reaction conditions and product distribution are listed in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to a catalytic cracking method. The method comprises the following steps: (1) feeding catalytic cracking raw material oil into the first reaction zone of a catalytic cracking reactor, contacting a catalytic cracking catalyst, and carrying out a first catalytic cracking reaction; (2) continuously carrying out a second catalytic cracking reaction on the obtained first reactionproduct and a semi-spent catalyst in the second reaction zone of the catalytic cracking reactor to obtain a second reaction product and a spent catalyst, sending an oxygen-containing compound into thesecond reaction zone of the catalytic cracking reactor, contacting the first reaction product and the semi-spent catalyst, and carrying out a second catalytic cracking reaction. The method provided by the invention can improve the heat distribution of the catalytic cracking reactor and improve the distribution of reaction products.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner CHINA PETROLEUM & CHEM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap