Water-based curtain-coating two-component polyurethane coating and preparation method thereof

A two-component polyurethane and water-based polyurethane technology, applied in the field of coatings, can solve problems such as floating color and blooming, and achieve the effects of increasing stability, good compatibility, and avoiding shrinkage cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

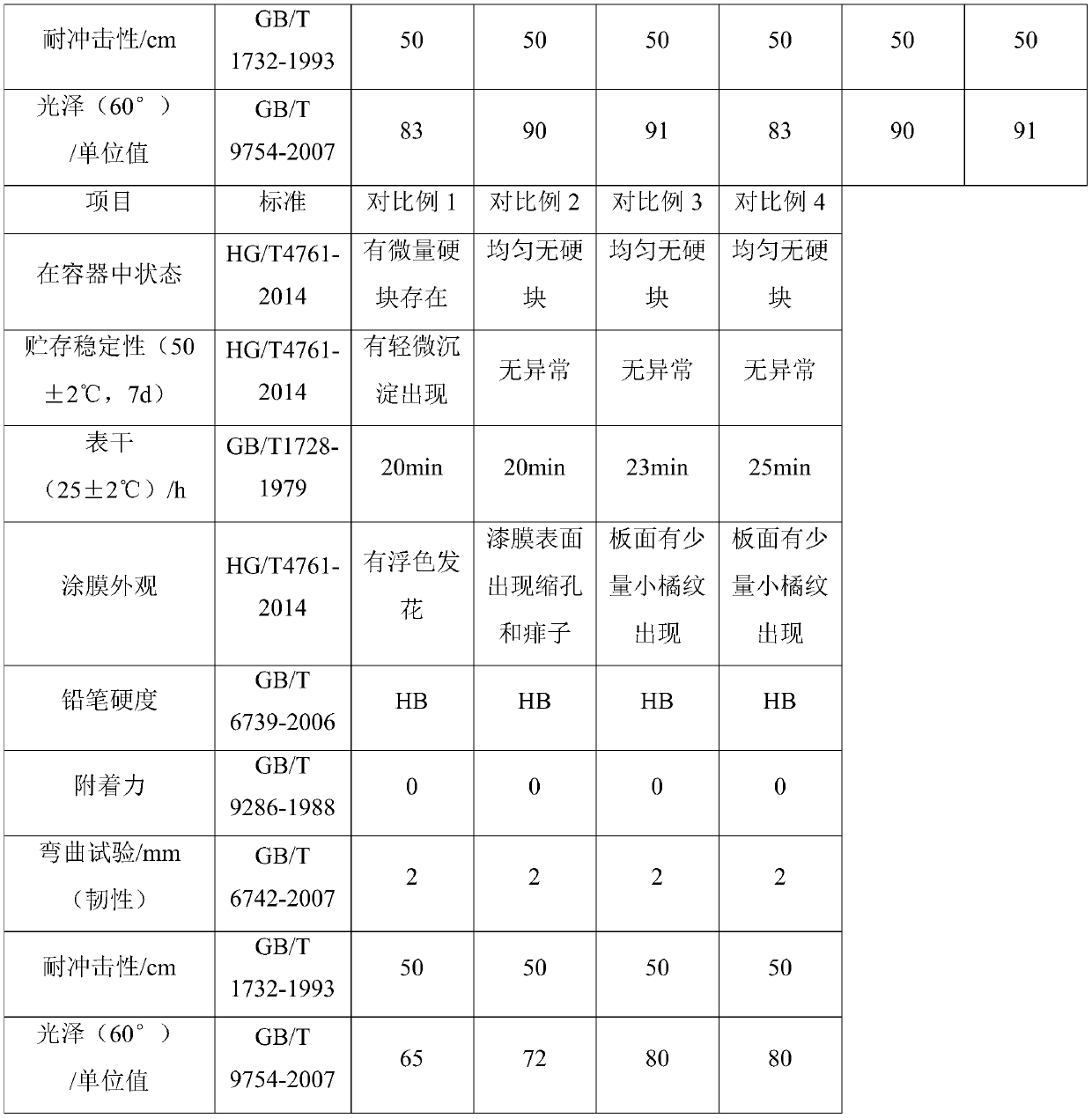

Examples

Example Embodiment

[0033] Example 1

[0034] A water-based curtain coating two-component polyurethane coating, including component A and component B;

[0035] The A component includes the following components by mass percentage:

[0036] Waterborne anionic polyurethane dispersion 45%, wetting and dispersing agent 1.2%, defoaming agent 1.2%, pigment 20%, co-solvent 4%, leveling agent 0.6%, thickening agent 0.5% and deionized water 27.5%;

[0037] Among them, the aqueous anionic polyurethane dispersion is Bayer's Dispercoll U53; the wetting and dispersing agent is composed of TEGO 755W and Surfynol 104E with a mass ratio of 3:1; the defoaming agent is composed of BYK028 and TEGO with a mass ratio of 1:1 Airex902 is composed of; the pigment is composed of titanium dioxide and carbon black with a mass ratio of 9:1; the cosolvent is Dow Chemical’s dipropylene glycol methyl ether; the leveling agent is composed of BYK3566 with a mass ratio of 1:1 and Afcona3587 composition; the thickener is Hemmings RHEOLATE 27

Example Embodiment

[0045] Example 2

[0046] A water-based curtain coating two-component polyurethane coating, including component A and component B;

[0047] The A component includes the following components by mass percentage:

[0048] Waterborne anionic polyurethane dispersion 55%, wetting and dispersing agent 1%, defoaming agent 0.8%, pigment 18%, co-solvent 4.9%, leveling agent 0.5%, thickener 0.3% and deionized water 19.5%;

[0049] Among them, the aqueous anionic polyurethane dispersion is Bayer's Dispercoll U53; the wetting and dispersing agent is composed of TEGO 755W and Surfynol 104E with a mass ratio of 4:1; the defoaming agent is composed of BYK028 and TEGO with a mass ratio of 1:1.2 Airex902; the pigment is composed of titanium dioxide and carbon black with a mass ratio of 8:1; the co-solvent is Dow Chemical’s dipropylene glycol methyl ether; the leveling agent is composed of BYK3566 with a mass ratio of 1.5:1 and Afcona3587 composition; the thickener is Hemmings RHEOLATE 278;

[0050] The B

Example Embodiment

[0057] Example 3

[0058] A water-based curtain coating two-component polyurethane coating, including component A and component B;

[0059] The A component includes the following components by mass percentage:

[0060] 60% aqueous anionic polyurethane dispersion, 0.8% wetting and dispersing agent, 0.5% defoaming agent, 15% pigment, 5.3% cosolvent, 0.3% leveling agent, 0.2% thickening agent and 17.9% deionized water;

[0061] Among them, the aqueous anionic polyurethane dispersion is Bayer's Dispercoll U53; the wetting and dispersing agent is composed of TEGO 755W and Surfynol 104E with a mass ratio of 5:1; the defoamer is composed of BYK028 and TEGO with a mass ratio of 1:1.5 Airex902 is composed of; the pigment is composed of titanium dioxide and carbon black with a mass ratio of 10:1; the cosolvent is Dow Chemical’s dipropylene glycol methyl ether; the leveling agent is composed of BYK3566 and a mass ratio of 2:1 Afcona3587 composition; the thickener is Hemmings RHEOLATE 278;

[0062]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap