Management method and system for parts in production process

A production process and management method technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as difficulty in finding parts, placing them in different containers, exceeding, etc., to improve the placement rate and utilization rate, improve Placement and circulation efficiency, avoiding the effect of low placement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

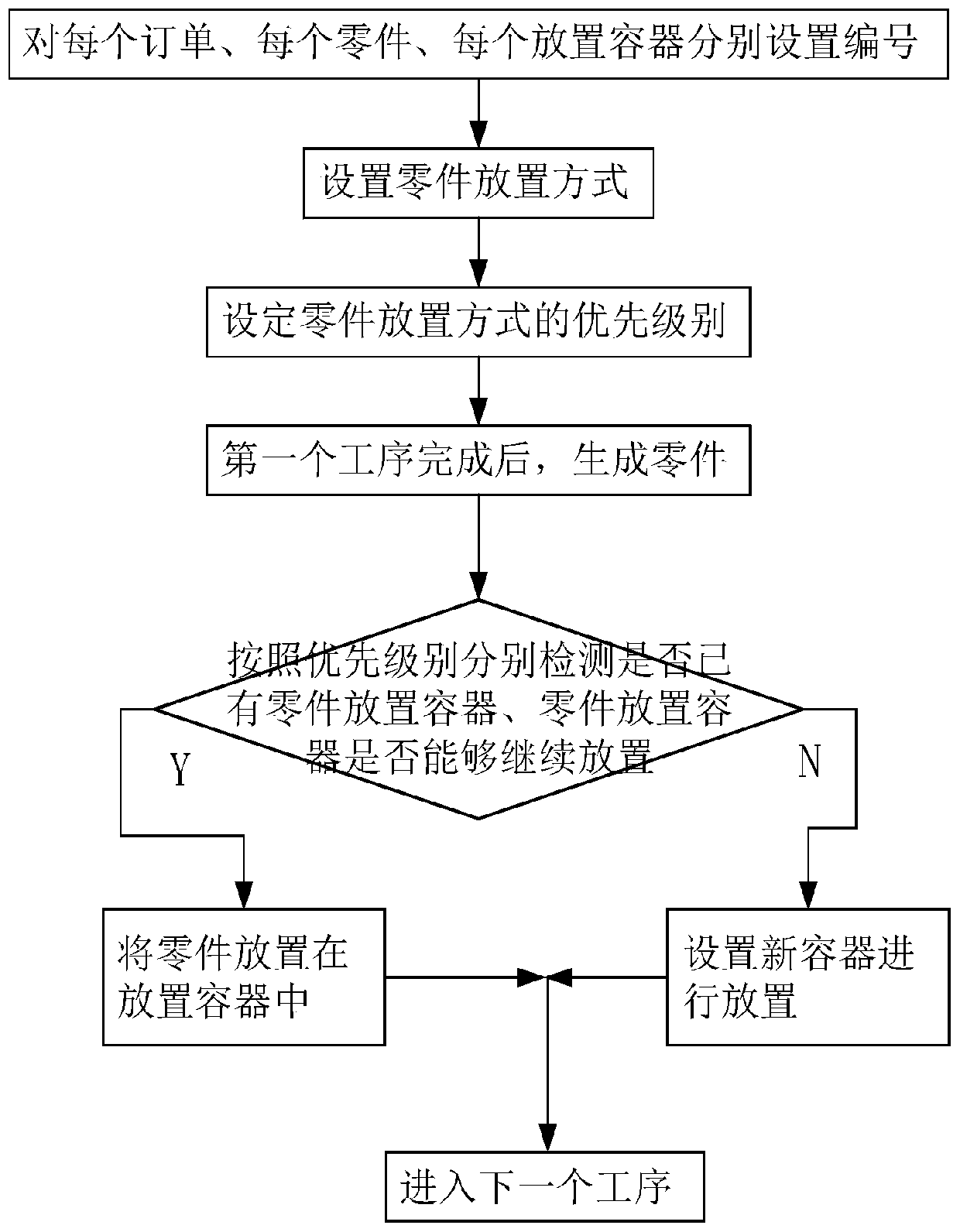

[0068] A method for managing parts in the production process of the present invention, such as figure 1 shown, including the following steps:

[0069] S1. Set numbers for each order, each part, and each storage container;

[0070] S2, setting the part placement method;

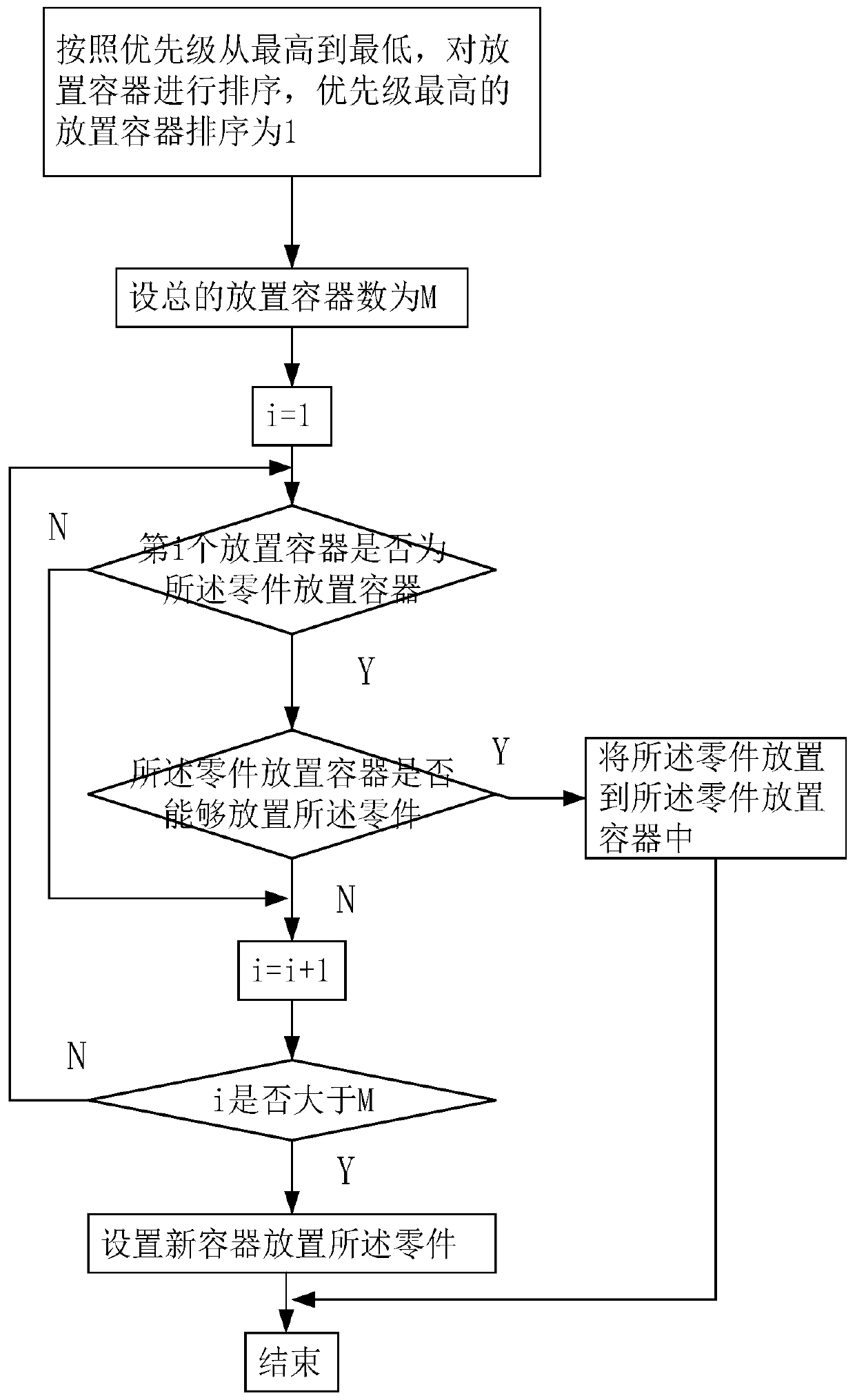

[0071] S3. Setting the priority level of the part placement method;

[0072] S4. After the first process is completed, the parts are generated;

[0073] S5. Check respectively according to the priority level whether there is a part storage container and whether the parts storage container can continue to be placed, if so, go to the next step, if not, go to S7;

[0074] S6, place the part in the part placement container, turn to S8;

[0075] S7, setting a new container for placement;

[0076] S8. Go to the next process and turn to S5.

[0077] In a specific embodiment of the present application, in step S1, a number is set for each order, including setting a number for each process in each order, and the sam

specific Embodiment 2

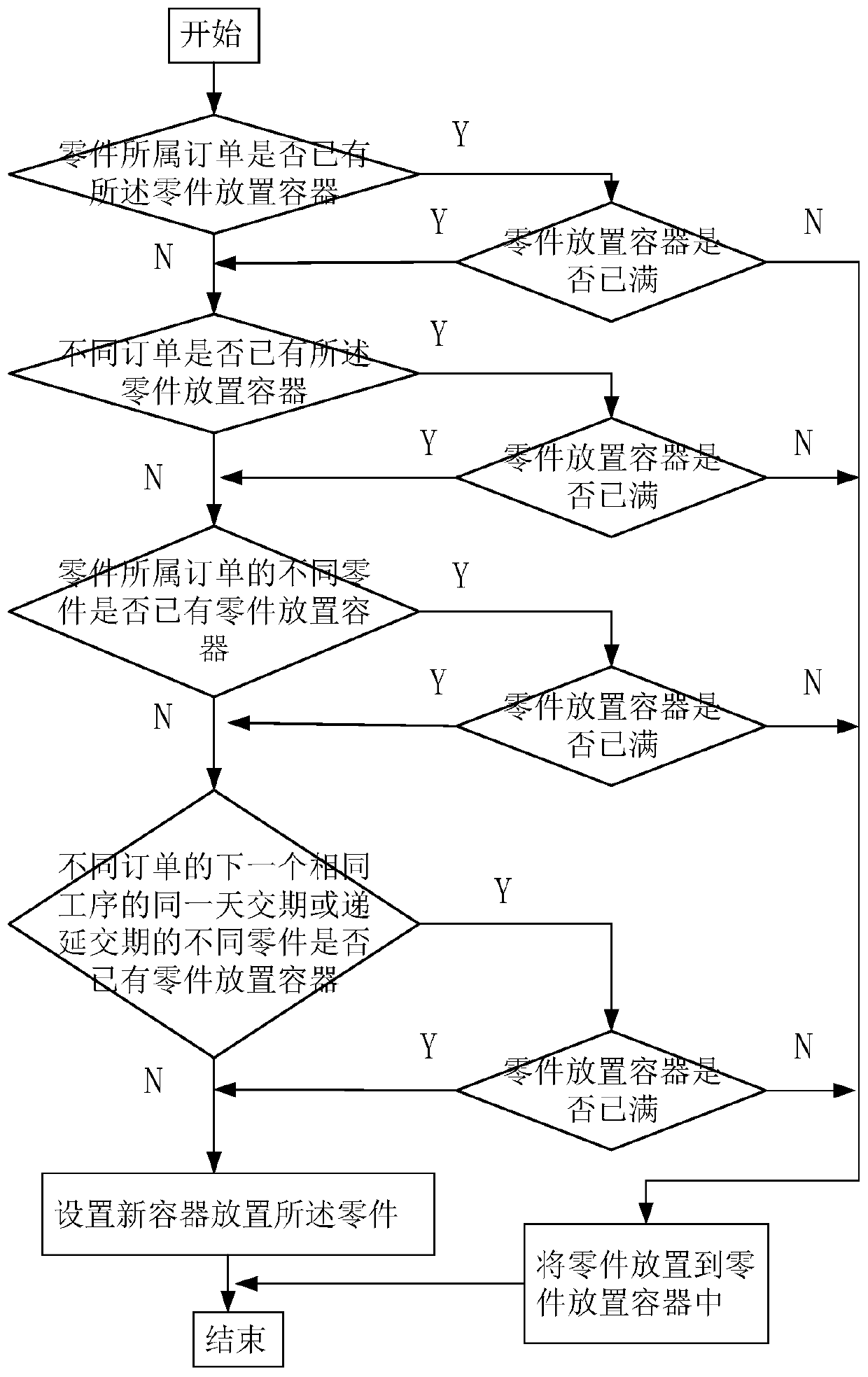

[0103] A management system for parts in the production process, including a display device, an input device, and a control module. The display device is used to display the part number, order number, container number, and retail quantity in the container, and the input device is used to input relevant parameters. . Select the container placement method, and the relevant parameters include the part number, order number, and container number. The control module is used to give the parameters of the part placement container according to whether the part placement container is full and the container placement method; the management system applies the management method to manage the part placement.

[0104] For the same order or multiple orders, the placement of parts consists of the following steps:

[0105] D1, start;

[0106] D2. The blanking is completed, the parts are generated, and the part numbers are obtained;

[0107] D3. Check whether the part has a corresponding storage c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap