Raw material cooking equipment for wine making

A technology of cooking equipment and raw materials, which is applied in the field of cooking equipment for raw materials for brewing, can solve problems such as uneven heating, waste of raw materials, uncontrollable temperature, etc., achieve uniform heating and ensure the effect of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

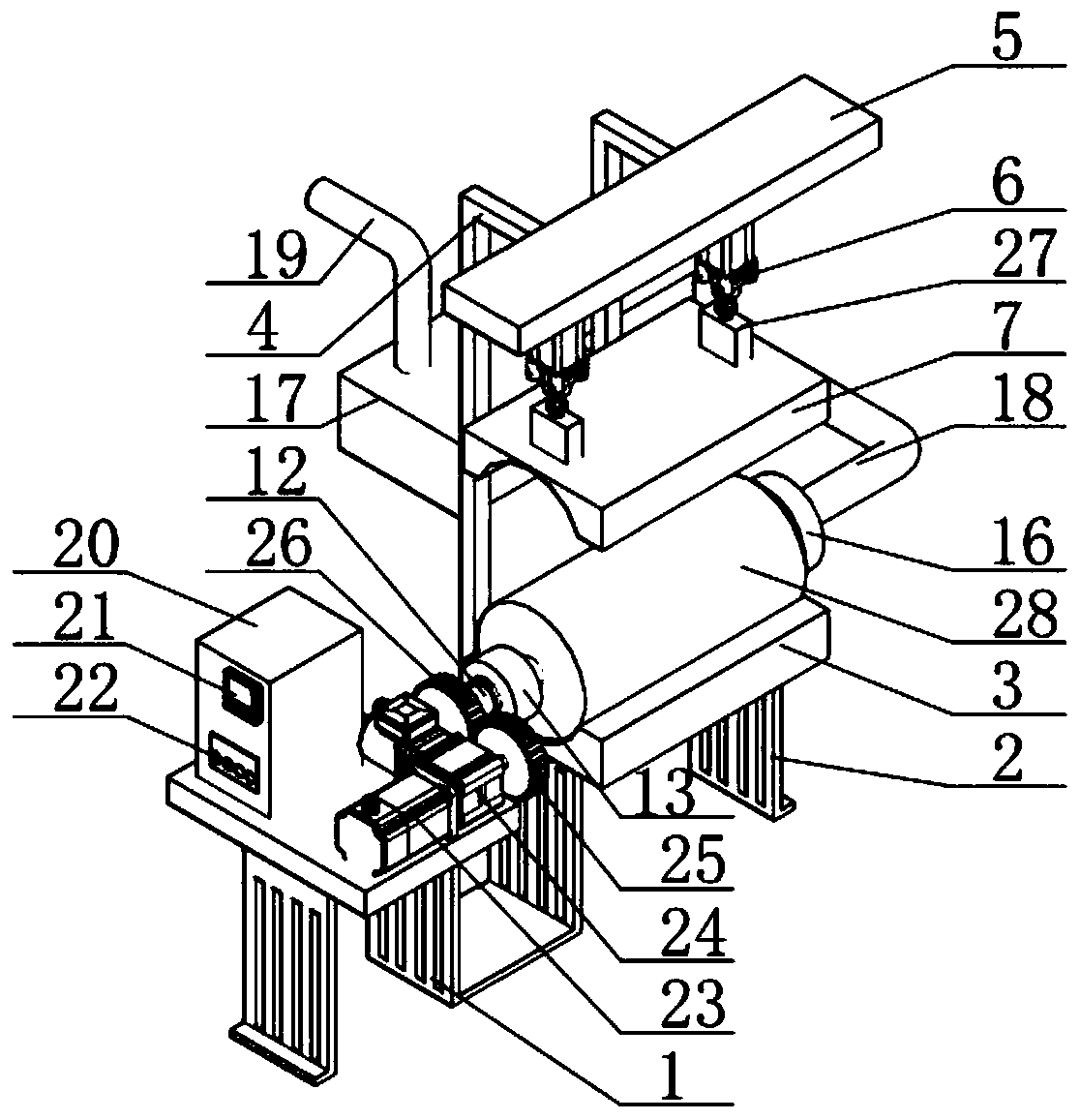

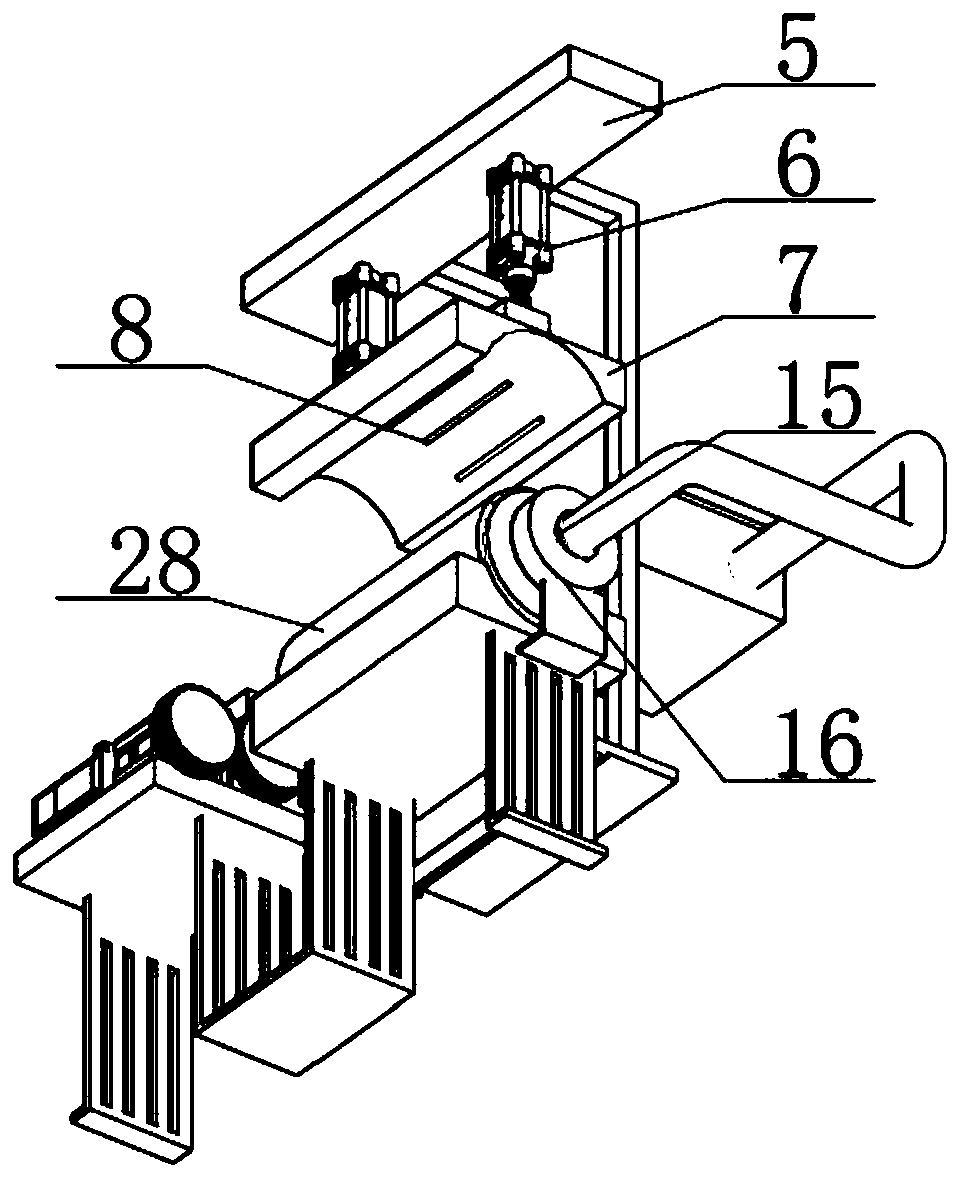

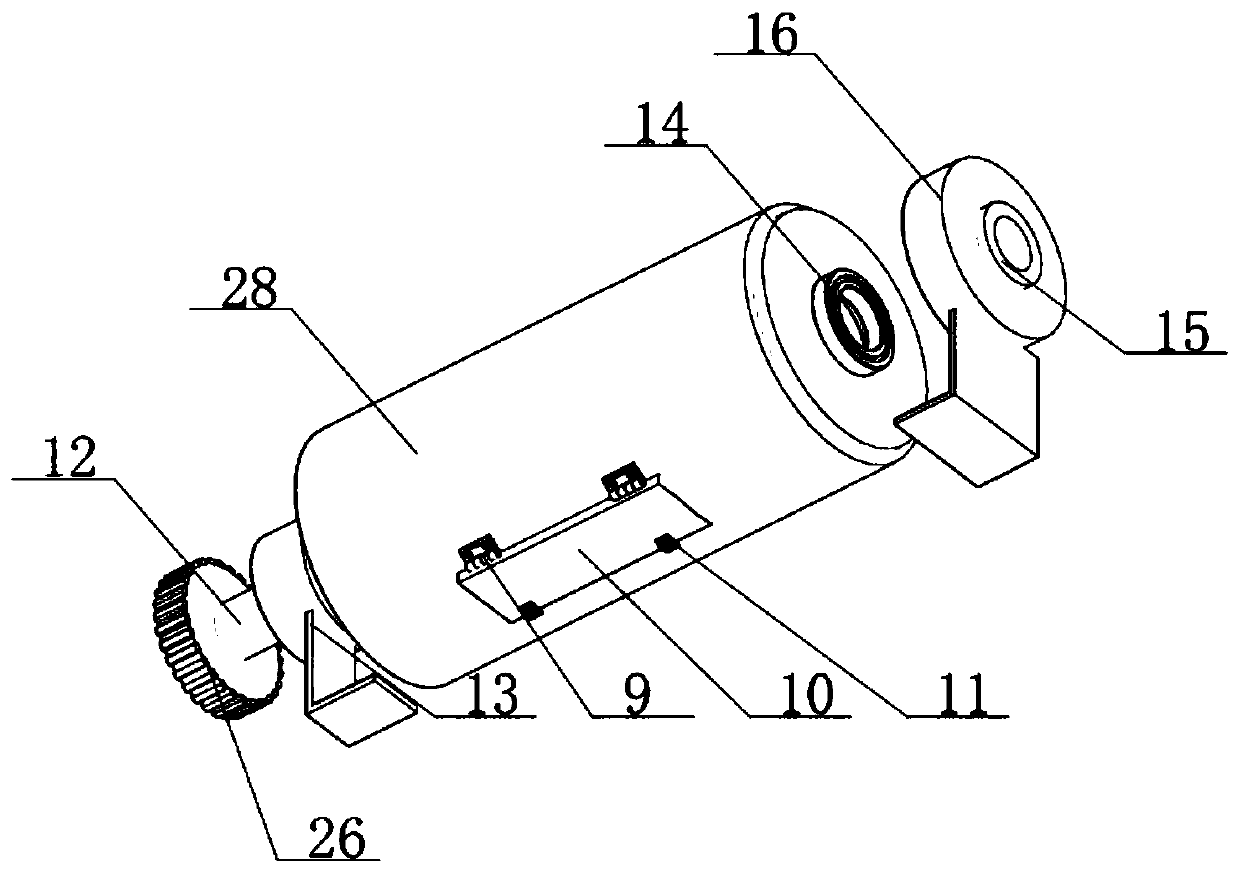

Embodiment 1

[0024] see figure 1 —3. A raw material cooking equipment for brewing, including a first support 1 and a second support 2, the upper part of the first support 1 is fixedly installed with a power mechanism, and the upper part of the second support 2 is fixedly installed with a lower heating ring 3. The upper mounting platform 5 is fixedly connected to the second support 2 through the connecting frame 4. There are multiple sets of electric telescopic cylinders 6 fixedly installed on the bottom of the upper mounting platform 5. The bottom of the electric telescopic cylinders 6 is fixedly connected to the upper heating ring 7. , through the electric telescopic cylinder 6, the upper heating ring 7 can be driven to reciprocate linearly up and down. The upper heating ring 7 corresponds to the lower heating ring 3. Both the upper heating ring 7 and the lower heating ring 3 are provided with arc-shaped The groove, the upper heating ring 7 and the inner wall of the lower heating ring 3 are

Embodiment 2

[0028] see figure 1 —3. A raw material cooking equipment for brewing. On the basis of the first embodiment, further, an integrated controller 20 is fixedly installed on the first support 1. The integrated controller 20 includes a control box and is arranged inside the control box. A controller with a single-chip microcomputer as the core, a setting panel 21 and a control panel 22 are arranged on the outer wall of the control box. The setting panel 21 is a device for parameter setting, which mainly includes a display screen and a setting button. The panel 22 is provided with a control button, and a temperature sensor is fixedly installed inside the cooking cylinder 28, and the controller is connected with the power mechanism, the electric telescopic cylinder 6, the exhaust fan, the temperature sensor, the setting panel 21, the control panel 22 and the heating pipe 8 , so that the temperature can be set through the setting panel 21, the temperature sensor detects the temperature in

Embodiment 3

[0032] see figure 1 —3. A raw material cooking equipment for brewing. In Embodiment 1, the power connection between the power mechanism and the rotating shaft 12 has two ways, one of which is that the power mechanism includes a motor 23 and a reducer 24, and the motor 23 and the speed reducer 24 power connections, the power output shaft of the reducer 24 is fixedly equipped with a first gear 25, and the rotating shaft 12 is fixedly equipped with a second gear 26, and the first gear 25 is meshed with the second gear 26;

[0033] The other is that the power mechanism includes a motor 23 and a reducer 24, the motor 23 is connected to the reducer 24 in power, the first pulley is fixedly installed on the power output shaft of the reducer 24, and the second pulley is fixedly installed on the rotating shaft 12. , the first pulley and the second pulley are connected by a belt;

[0034]Further, the bottom of the electric telescopic cylinder 6 is fixedly connected with a heat insulation p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap