Composite lithium ion battery cathode material, lithium ion battery cathode, lithium battery, battery module, battery pack and vehicle

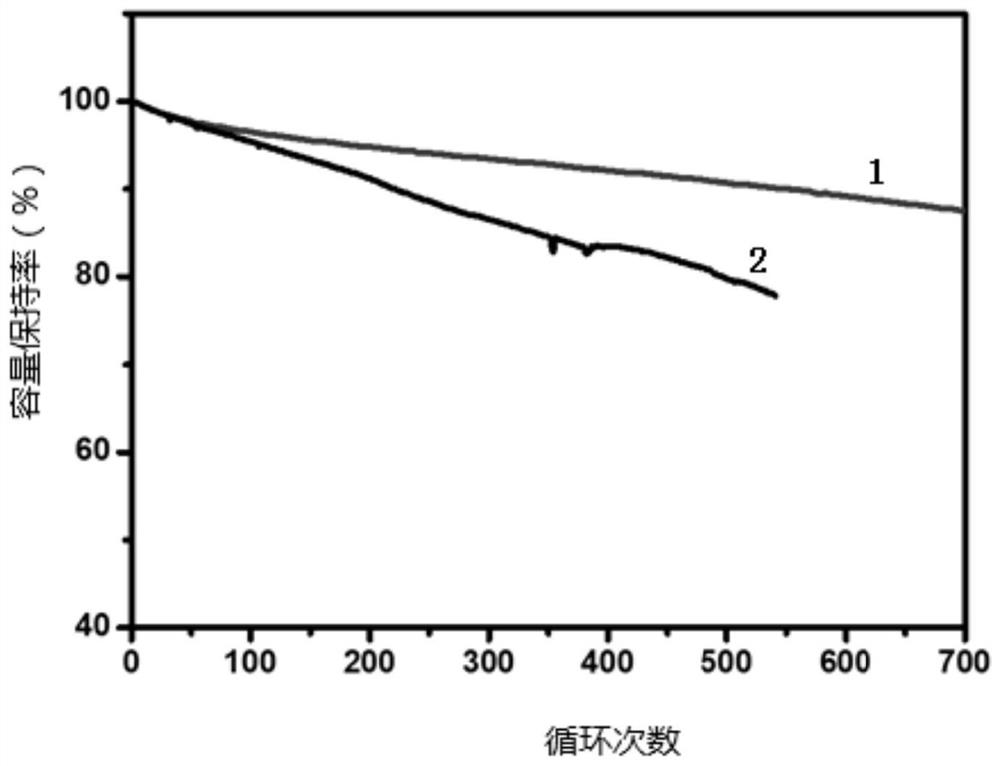

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, batteries, positive electrodes, etc., can solve the problems of battery performance degradation, structural instability, and rock-salt equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

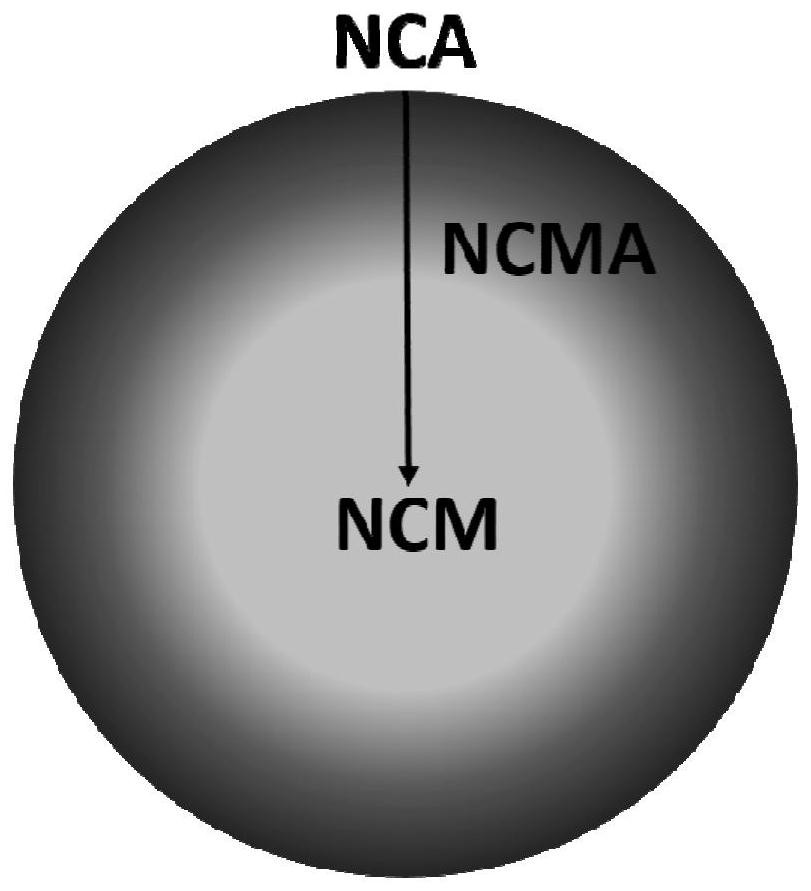

[0042] According to the present invention, the preparation method of the positive electrode material may include:

[0043] (a) adjust the pH value of the aqueous system containing nickel salt, cobalt salt and manganese salt to co-precipitate nickel-cobalt-manganese ternary hydroxide precursor;

[0044] (b) continue to add nickel salt, cobalt salt and the salt containing element E, adjust the pH value and co-precipitate to form the nickel-cobalt-manganese ternary hydroxide precursor coated with nickel, cobalt and element E;

[0045] (c) The nickel-cobalt-manganese ternary hydroxide precursor coated with nickel, cobalt and element E is mixed with lithium hydroxide and sintered, crushed and washed to prepare a composite lithium-ion battery positive electrode material.

[0046] According to the present invention, in steps (a) and (b), the pH values can be the same or different, and the pH values in step (a) and the pH values in step (b) can be 10-12 respectively;

[0047] Acco

Embodiment 1

[0074] This example is to illustrate the cathode material prepared by the method of the present invention.

[0075] (1) Nickel sulfate, cobalt sulfate, and manganese sulfate are mixed and dissolved in deionized water. The total metal molar concentration of sulfuric acid is 1M, wherein the molar ratio of nickel, cobalt, and manganese is 9:1:1, and the sodium hydroxide solution Add it dropwise to the above solution at the same time with ammonia water, adjust the pH of the solution to 11, and precipitate out to obtain a nickel-cobalt-manganese ternary hydroxide precursor, wherein the concentration of sodium hydroxide is 0.5M, and the concentration of ammonia water is 0.5M;

[0076] (2) In the precursor solution obtained above, continue to add the solution of nickel sulfate, cobalt sulfate and aluminum sulfate, the total molar concentration of metal in the solution is 1M, the mol ratio of nickel, cobalt, aluminum is 80:5:15, Control the pH so that nickel, cobalt, and aluminum precipi

Embodiment 2

[0085] This example is to illustrate the cathode material prepared by the method of the present invention.

[0086] The positive electrode material was prepared in the same manner as in Example 1, except that aluminum oxide was replaced by zirconium oxide, and the amount of nickel sulfate, cobalt sulfate, manganese sulfate, lithium hydroxide and zirconium oxide used was such that:

[0087] As a result, the prepared positive electrode material is an ellipsoidal single crystal material with an average particle size of 2.1 μm; based on the total weight of the positive electrode material, the content of the element E in the surface layer is 4% by weight. The content in the layer is 2% by weight, and the content of the element E in the transition layer shows a decreasing trend;

[0088] Wherein, based on the total weight of the positive electrode material, the content of the surface layer is 2.5% by weight, the content of the transition layer is 6.5% by weight, and the content of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap