Cleaning and drying mechanism for silk fabrics

A drying mechanism and technology for silk fabrics, applied in textiles and papermaking, textile material processing, liquid/gas/steam fabric processing, etc., can solve problems such as cumbersome operation, achieve simple operation, high cleaning and drying efficiency, and improve cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

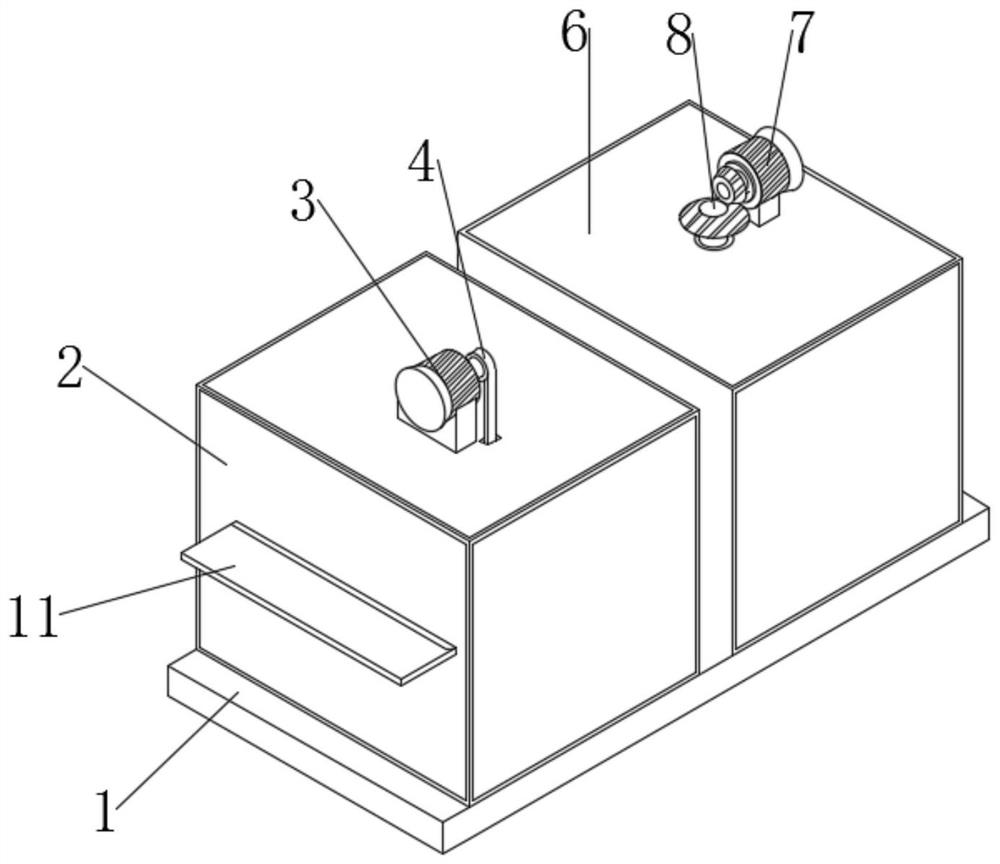

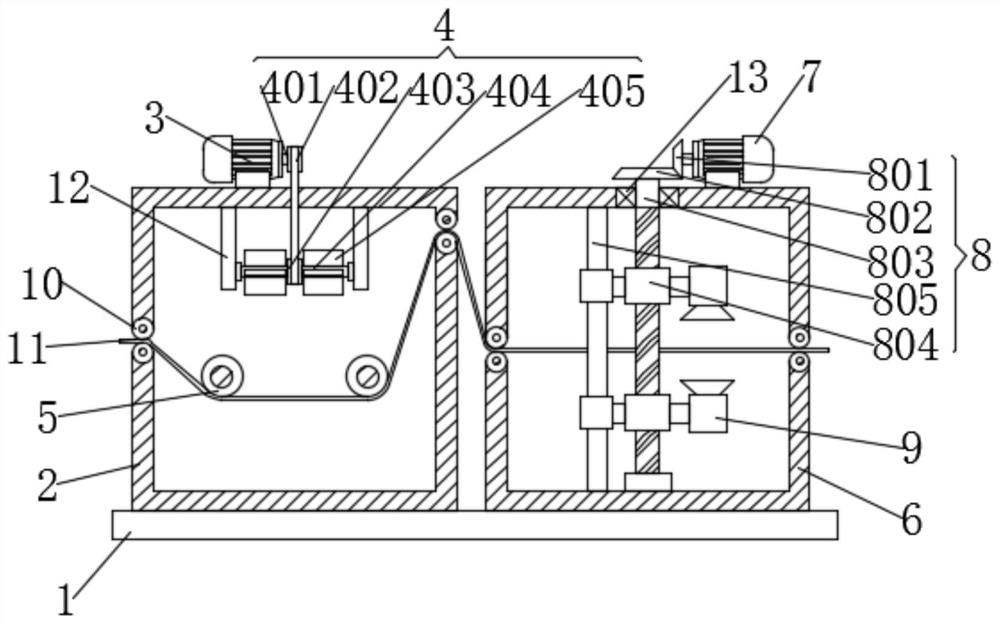

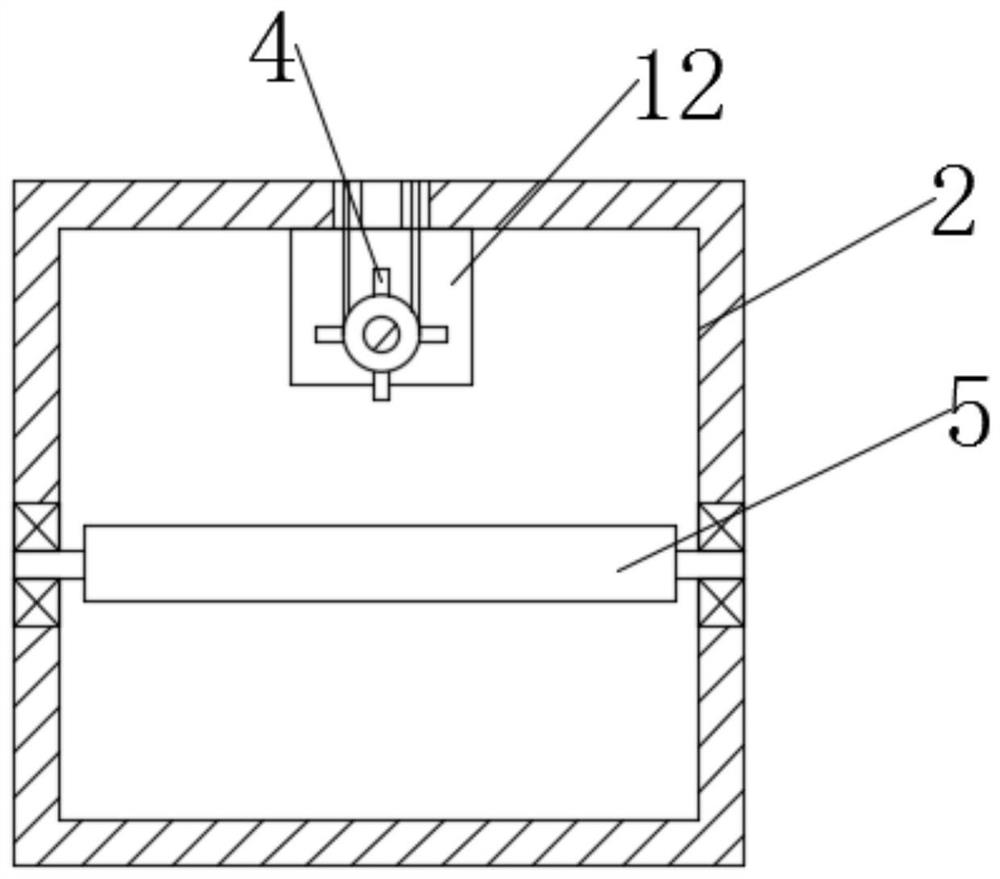

[0018] see Figure 1 to Figure 3 , the present invention provides a technical solution: a cleaning and drying mechanism for silk fabrics, including a bottom plate 1, a cleaning box 2 is arranged on the upper surface of the bottom plate 1, and both sides of the cleaning box 2 and the drying box 6 are provided with Guide rollers 10, silk fabrics 11 are arranged between the guide rollers 10, the inner top wall of the cleaning box 2 is fixedly connected with a support plate 12, one side of the support plate 12 is movably connected with the connecting shaft 404, and the upper surface of the cleaning box 2 is fixedly connected with a Cleaning motor 3, the output end of cleani

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap