Brushless control panel structure based on plastic package power tube

A technology of control board and power tube, which is applied in the direction of support structure installation, cooling/ventilation/heating transformation, etc., can solve the problems of field effect tube damage, contact area reduction, heat can not be quickly transferred to heat sink, etc., to reduce components Collision, the effect of improving heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034]Example

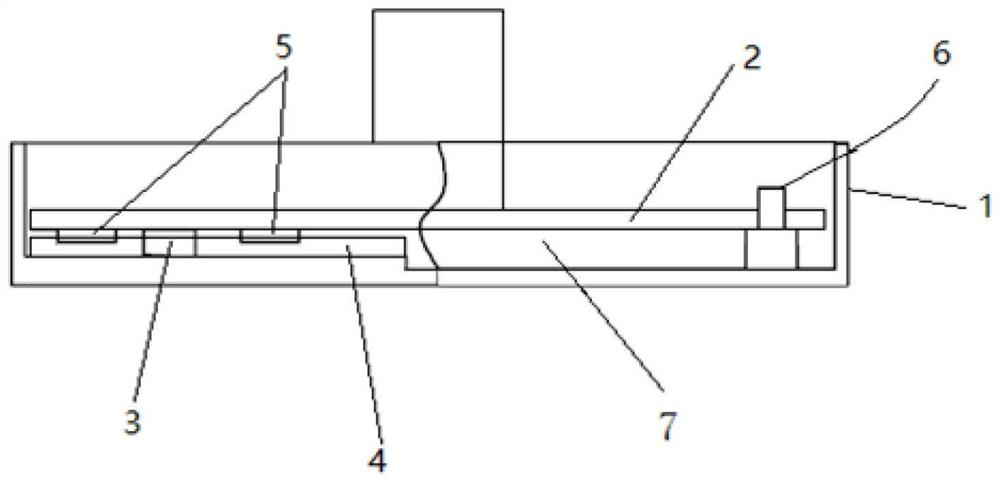

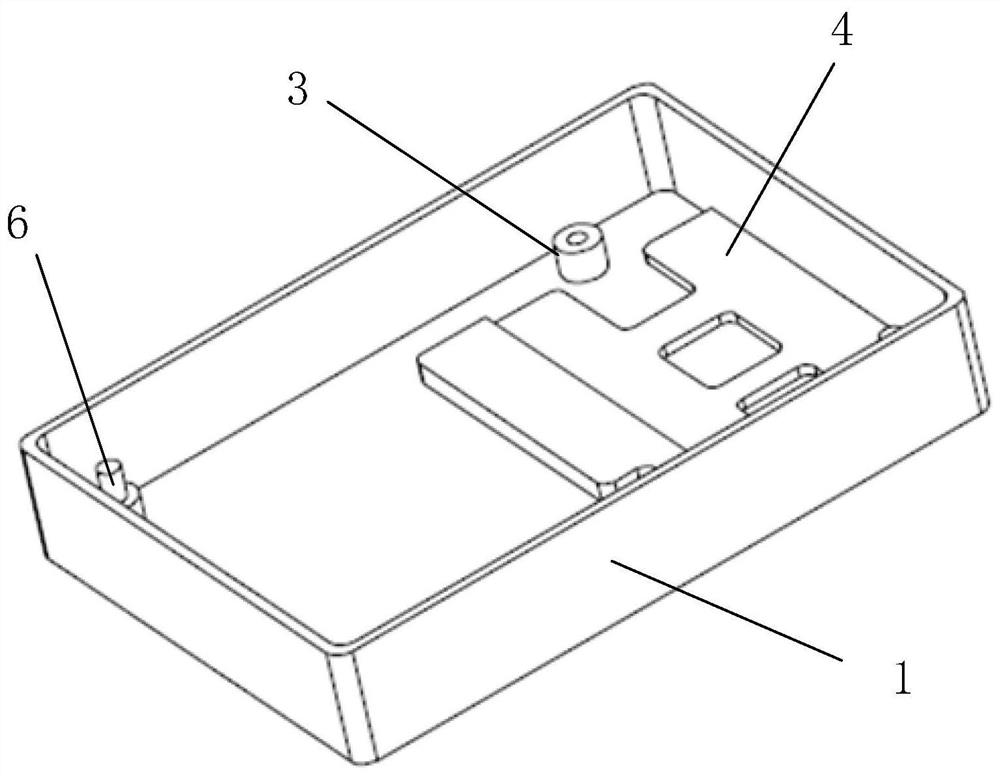

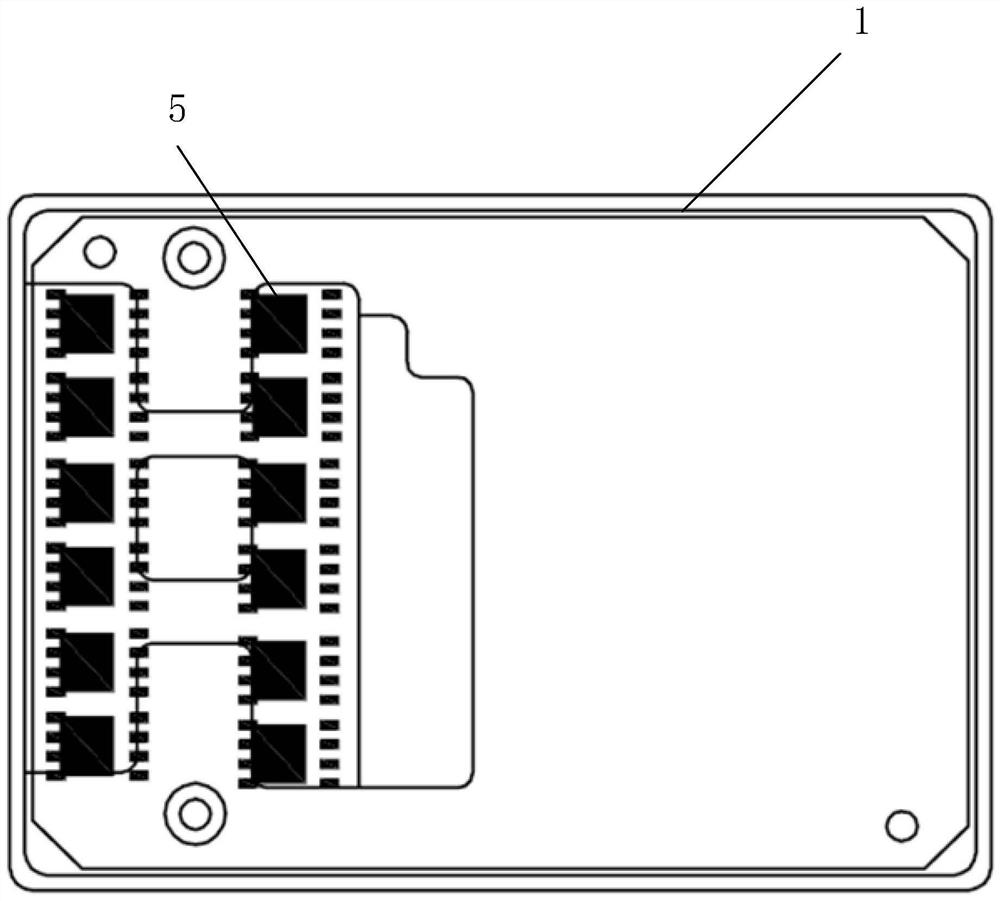

[0035]Such asfigure 1 ,figure 2 withimage 3As shown, a brushless control panel structure based on the plastic power tube, includes a package 1, and a first fixed post 3 is provided on one side of the bottom layer of the package cartridge 1, and another side of the bottom layer of the package cartridge 1 There is a second fixing post 6, the height of the second fixing post 6 is flat to the height of the first fixing post 3, and the first fixed column 3 and the second fixing column 6 are provided with a brushless control panel 2. The field effect tube 5 at the bottom of the brushless control panel 2 is located at a gap between the bottom layer of the package cartridge 1, and a thin film heat transfer pad 4 is provided in the gap, the thin film heat transfer pad 4 and the field effect tube 5 and the package cartridge 1. The setting in which the field effect tube 5 is embedded in the film heat transfer pad 4, and the depth of the inline is 0.5 mm to 0.7 mm, and the bottom port

Example Embodiment

[0040]Example one

[0041]On the basis of the above embodiment, the bottom of the package cartridge 1 is stepped by a step structure, and the first fixed column and the film heat conductor are located on the high-order ladder of the package cartridge 1, and the height of the high-ladder is 1 mm, the film heat conduction The thickness of the pad 4 is 1.5 mm, and the height of the first fixed column 3 is 3 mm, and the field effect tube 5 is embedded in the groove 8 in the depth of 0.5 mm, which can make the field effect tube through the heat transfer pad and heat dissipation. The body is closely contacted, improves the heat dissipation effect, and the film heat conduction pad uses a silica gel pad to satisfy the toughness, high heat conductance coefficient has no contamination type, avoiding and sealing the infection. Field effect tubes and heat sinks can improve the contact surface while avoiding the field effect tube and heat dissipating body friction damage field effect tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap