Wire shearing type double-nozzle carbon fiber 3D printing equipment and using method thereof

A 3D printing and carbon fiber technology, applied in metal processing equipment, 3D object support structure, additive manufacturing, etc., can solve the problems of long production cycle, disparity in carbon fiber surface quality, and complex manufacturing and molding process, and achieve convenient and flexible use. The effect of promoting printing quality and material densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

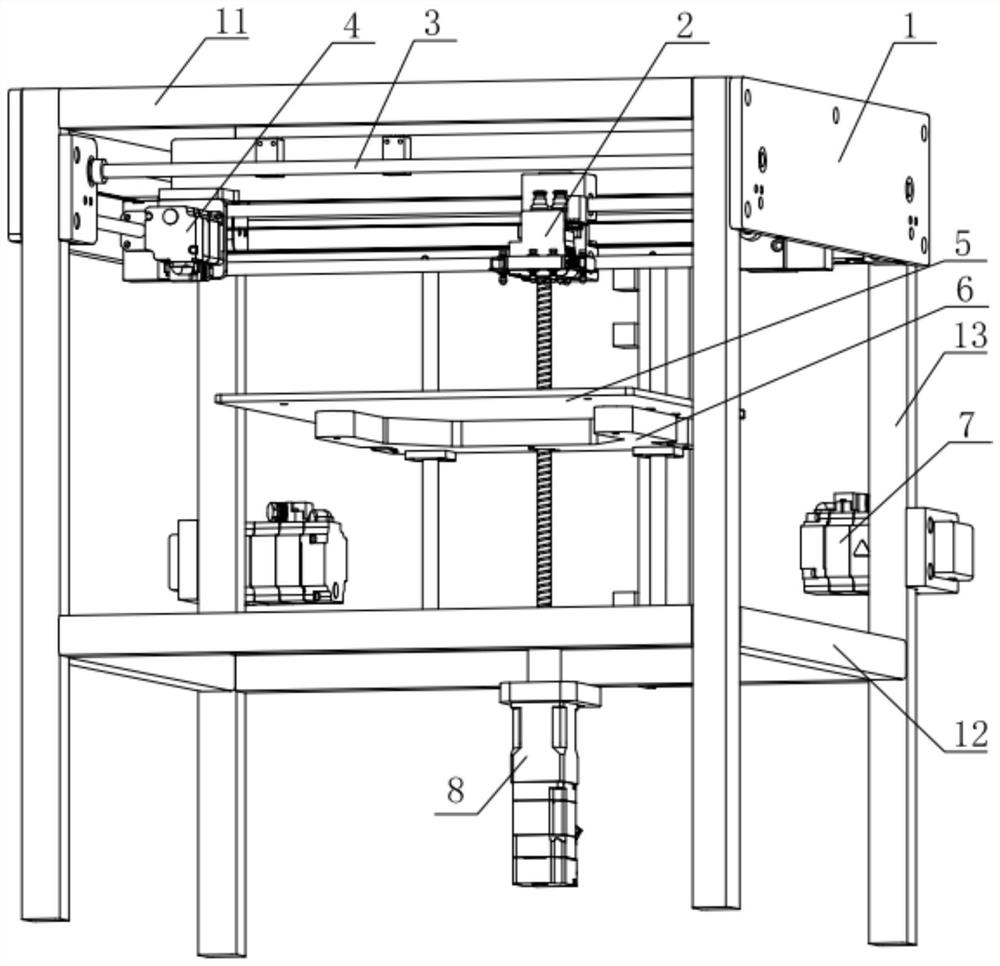

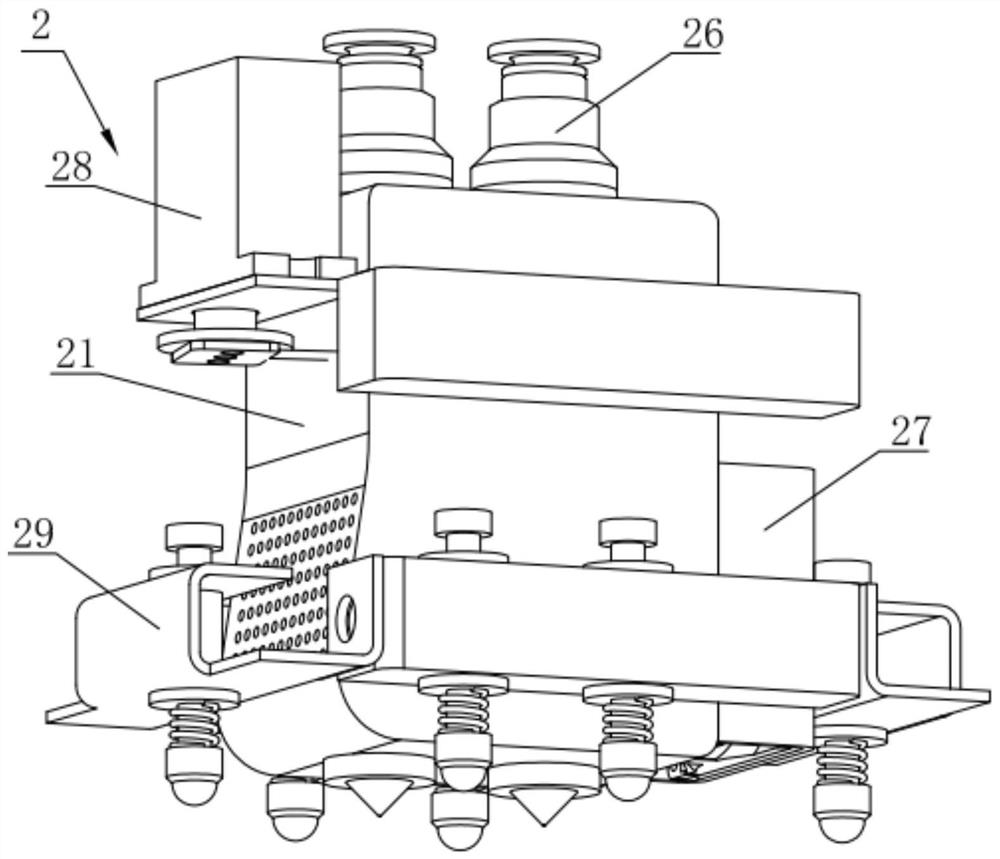

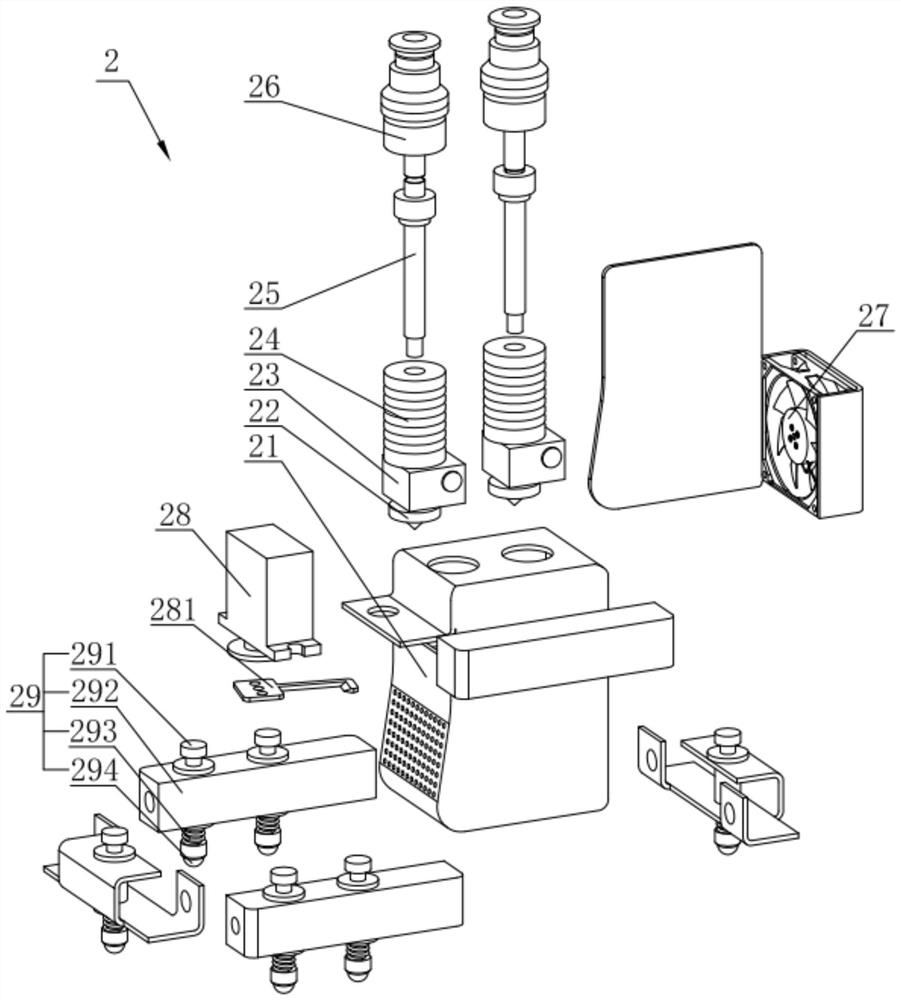

[0049] Such as figure 1 As shown, a carbon fiber 3D printing device of a wire-cutting type double-nozzle head in this embodiment includes an upper beam assembly 11 and a lower beam assembly 12 arranged at intervals up and down and in a frame-shaped structure, and the upper beam assembly 11 and the lower beam assembly 12. Columns 13 are installed at each corner to form a frame; Y-direction moving assembly 3 is installed on the upper beam assembly 11, and X-direction moving assembly 4 that moves along its Y direction is installed on the Y-direction moving assembly 3, and the X-direction moving assembly 4 moves along the Y direction. The assembly 4 is equipped with a nozzle assembly 2 that moves along its X direction, and a printing table 5 is installed at intervals directly below the nozzle assembly 2, and the printing table 5 is lifted and low

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap