Polyamic acid composition, polyimide composition, polyimide film and polyimide copper-clad plate

A polyimide film and polyamic acid technology, applied in the field of functional polymers, can solve the problem of low bonding force between polyimide and copper, and achieve the effect of solving the low bonding force and improving the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

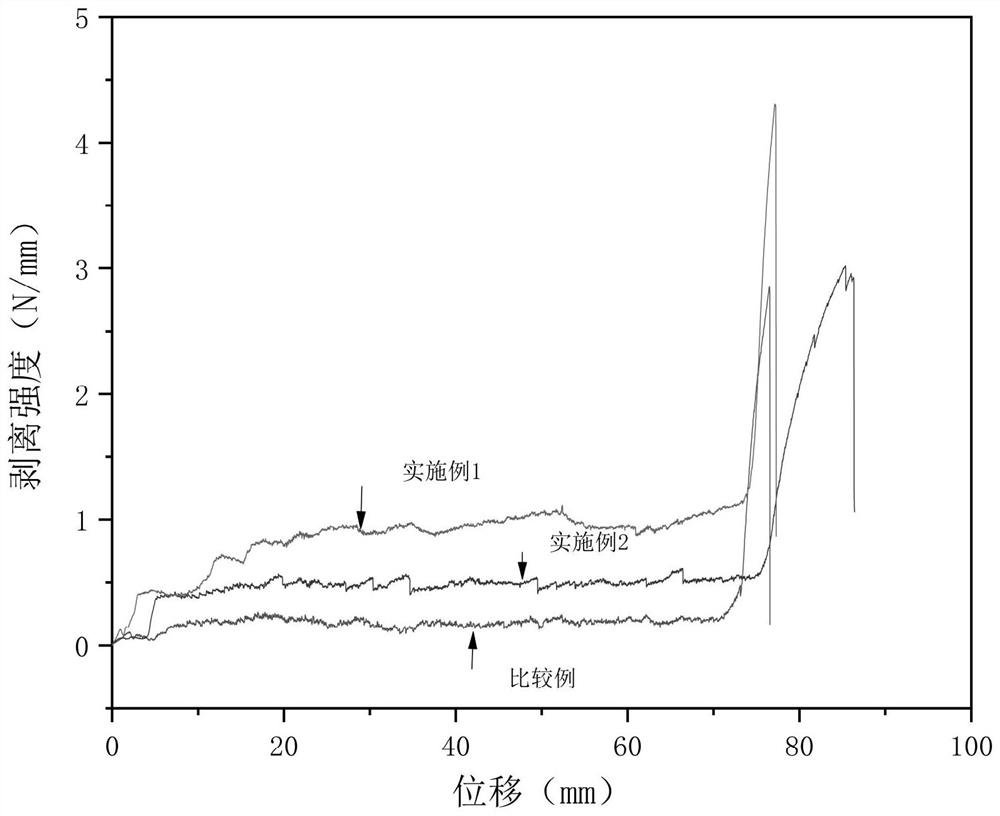

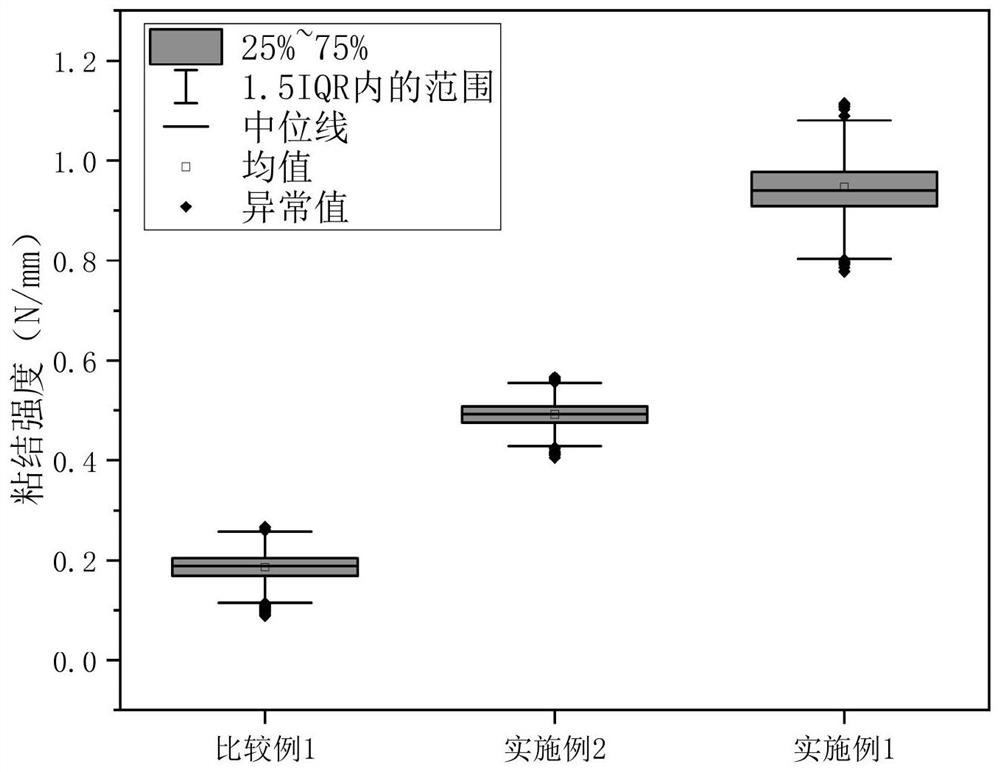

[0035] Add 0.2g of 2,4-diamino-6-hydroxypyrimidine to the above-mentioned polymer A glue, stir in an ice-water bath for 6 hours to obtain glue A, and evenly coat glue A with a roughness of less than 0.1 μm copper foil, and then thermally imidized in a temperature-programmed oven at 350°C under a nitrogen atmosphere to obtain a polyimide film.

Embodiment 2

[0037] Add 0.2g of 4,6-dihydroxypyrimidine to the above-mentioned polymer A glue, stir in an ice-water bath for 6 hours to obtain glue B, and evenly coat glue B on a copper foil with a roughness less than 0.1μm by spin coating Then heat imidization in a temperature-programmed oven at 350°C under a nitrogen atmosphere to obtain a polyimide film.

Embodiment 3

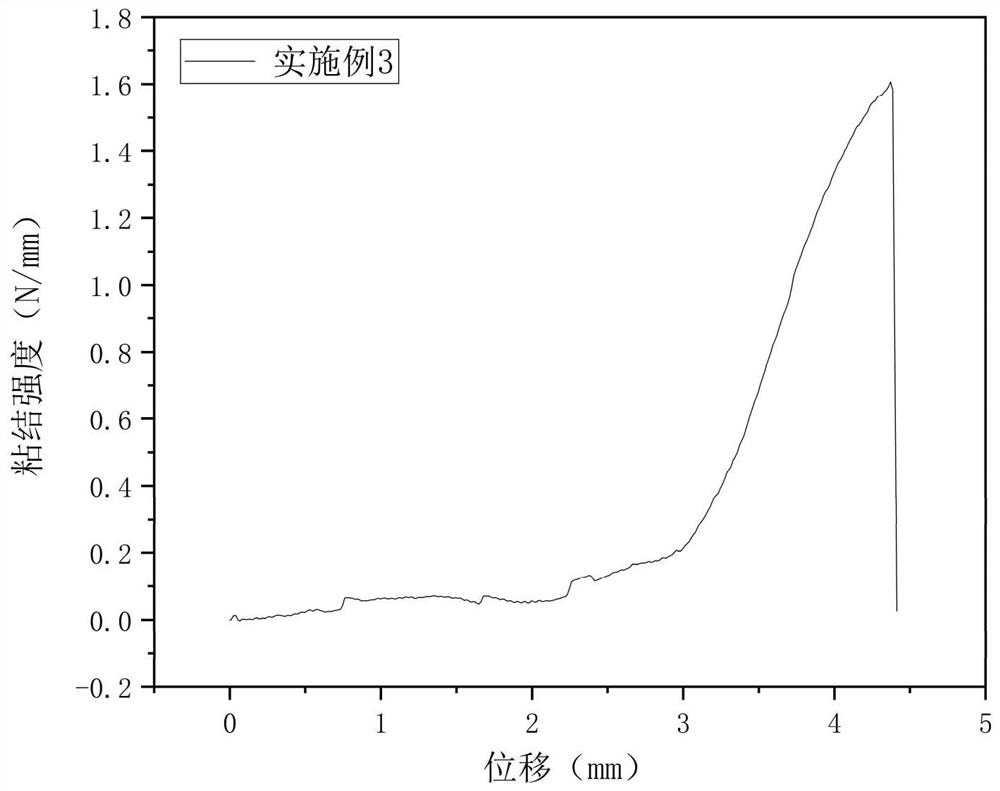

[0039] Add 0.2 g of 2-aminopyridine to the above-mentioned polymer A glue, and stir in an ice-water bath for 6 hours to obtain glue C, which is uniformly coated on a copper foil with a roughness of less than 0.1 μm by a spin coating process, Then thermally imidize in a temperature-programmed oven at 350° C. under a nitrogen atmosphere to obtain a polyimide film.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap