Steel beam platform structure for C-shaped stockyard

A technology of platform structure and steel structure, which is applied in the direction of building structure and construction, can solve the problems of restricting the promotion and application of C-type stockyards, the low degree of civilized construction, and the large consumption of manpower and material resources, so as to reduce construction auxiliary costs and Project investment costs, reducing the amount of high-altitude construction work, and reducing the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

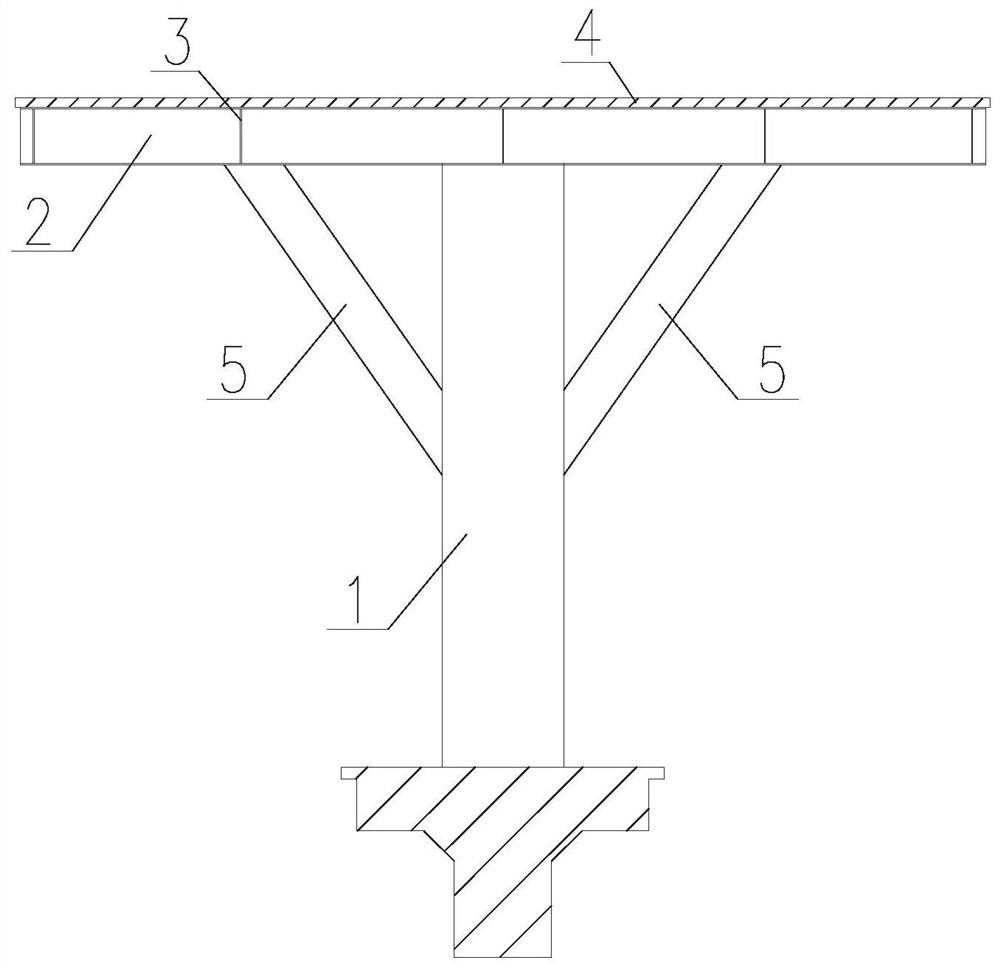

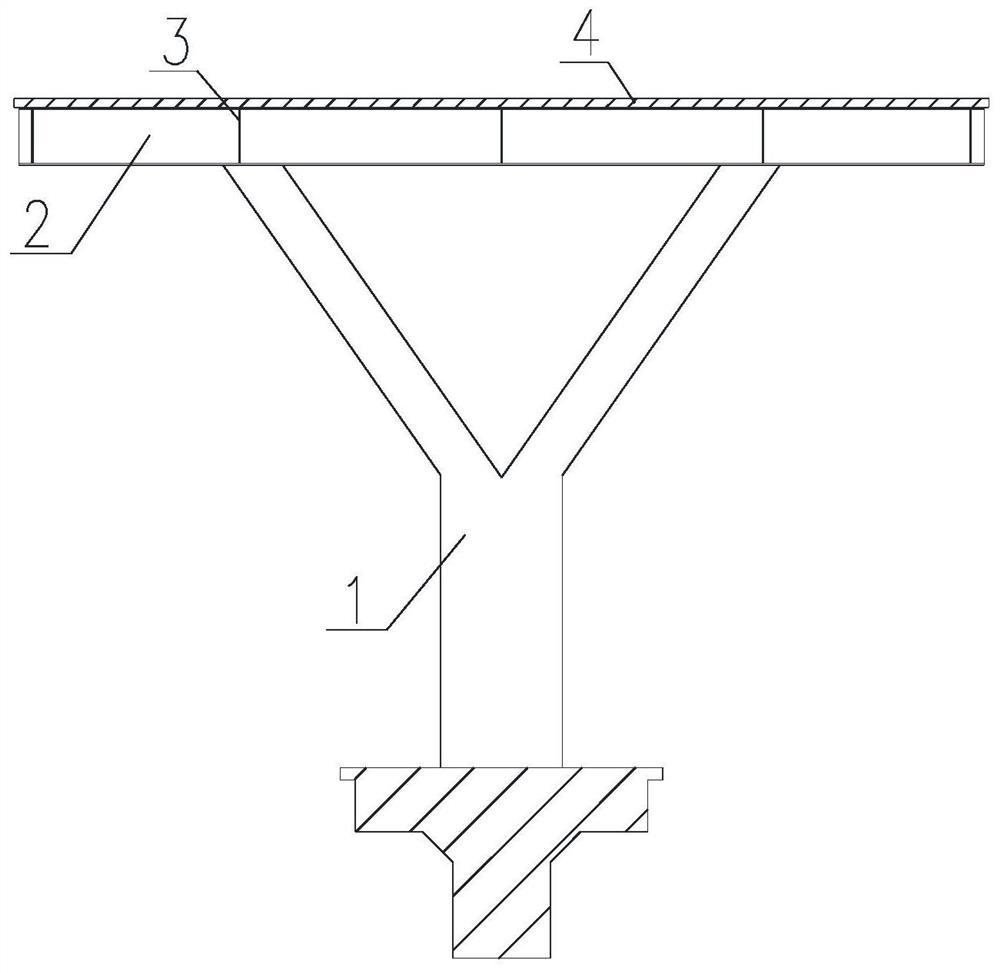

[0031] A steel beam platform structure for a C-type stockyard unloading vehicle, including a plurality of support seats 1 arranged at intervals along the longitudinal direction of the stockyard, and the upper part of the support seat 1 has a plurality of split limbs 5 distributed along the transverse direction of the stockyard, and the split limbs The top of 5 is provided with a prefabricated steel structure beam 2, and the prefabricated steel structure beam 2 is provided with a prefabricated steel structure longitudinal beam 3 arranged longitudinally along the stockyard, and a platform body is arranged on the prefabricated steel structure longitudinal beam 3, and the platform body is composed of several The platform board 4 is laid.

[0032] The beam 2 is a prefabricated part, which can be an H-shaped steel beam or a box-shaped steel beam. The support base 1 can be in the form of a split limb 5 with two spans or more at the top, and the support base 1 can be a steel column or a s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap