A kind of water-based color addition UV coating with long recoating interval time and preparation method and application thereof

A water-based, long-heavy technology, used in polyurea/polyurethane coatings, coatings, etc., can solve problems such as VOC can not meet, adverse customer benefits, reduce customer production efficiency, etc., to achieve the effect of extending the recoating interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The present invention also provides a preparation method for the water-based color addition UV coating, comprising the following steps:

[0089] The preparation method of component A of the water-based additive color UV coating is as follows:

[0090] 1. Prepare silver powder into silver paste, add silver powder, add deionized water, slowly add dispersant while stirring at 400-700r / min, disperse for 10 minutes, stop dispersing, and soak for 30 minutes. Continue to 400-700r / min, disperse for 10 minutes, set aside.

[0091] 2. Add the high-functionality UV resin dispersion into the dispersion tank, add deionized water, slowly add defoamer, wetting and leveling agent, film-forming aid, anti-settling agent, low The functional UV resin was dispersed at 1100-1500r / min for 20 minutes.

[0092] 3. Adjust the speed of the disperser to 300-500r / min, slowly add the water-based polyurethane dispersion, photoinitiator, and matting powder while stirring, and disperse at 1000-1

Embodiment 1

[0099] Component A: 50% high-functionality UV resin dispersion, 10% low-functionality UV resin dispersion, 20% aqueous polyurethane dispersion, 3% photoinitiator, 3% film-forming aid, 2% matting powder, moisturizing Wet leveling agent 0.5%, defoamer 0.2%, thickener 0.1%, anti-settling agent 1%, water-based silver paste 8%, PH adjuster 0.2%, diluent 2%.

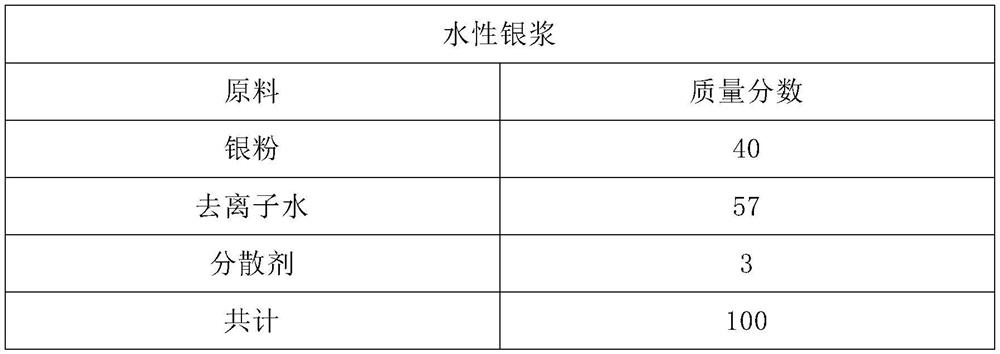

[0100] The composition of embodiment 1 water-based silver paste is shown in following table 1:

[0101] Table 1

[0102]

[0103] The above-mentioned water-based silver paste preparation method is as follows:

[0104] 1. Add the silver powder into the dispersion tank, add deionized water, slowly add the dispersant while stirring at 400 r / min, and disperse for 10 minutes.

[0105] 2. Stop dispersing and soak for 30 minutes. Continue to 400r / min, disperse for 10 minutes, set aside.

Embodiment 3

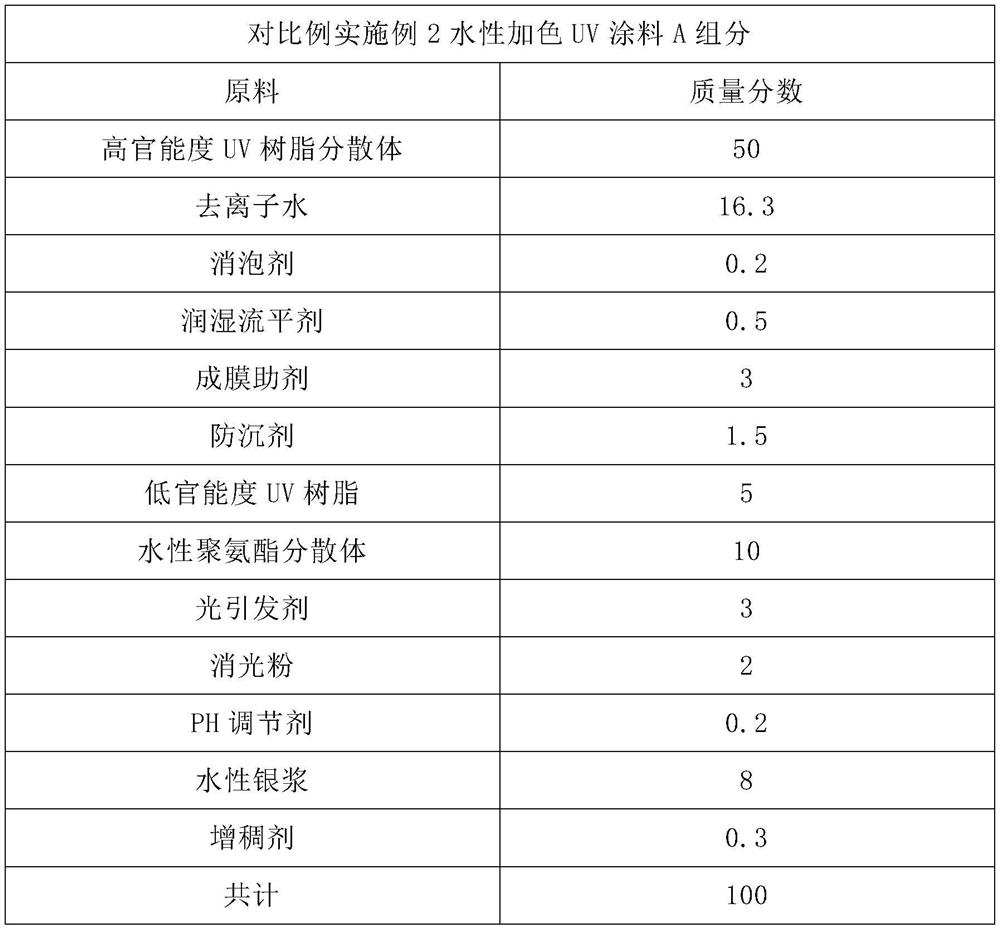

[0114] The A component of the water-based color addition UV coating of Example 3 is shown in Table 3 below

[0115] table 3

[0116]

[0117] The preparation method of component A of the water-based additive color UV coating is as follows:

[0118] 1. Add the high-functionality UV resin dispersion into the dispersion tank, add deionized water, slowly add defoamer, wetting and leveling agent, film-forming aid, anti-settling agent, low-functionality while stirring at 500 r / min UV resin, dispersed at 800r / min for 20 minutes.

[0119] 2. Adjust the speed of the disperser to 300r / min, slowly add the water-based polyurethane dispersion, photoinitiator, and matting powder while stirring, and disperse at 1000r / min for 20 minutes. The detection fineness is less than or equal to 12um, which is qualified.

[0120]3. Adjust the speed of the disperser to 500r / min, slowly add the PH adjuster while stirring, adjust the pH value of the paint to 8.3, add silver paste, and add the t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap