Miniaturized fiber-optic gyroscope based on time division multiplexing

A fiber optic gyroscope and time-division multiplexing technology, which is applied to Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, and measuring devices, can solve the problems of large circuit board size, high cost, and high power consumption, and achieve The effect of small size, low cost and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

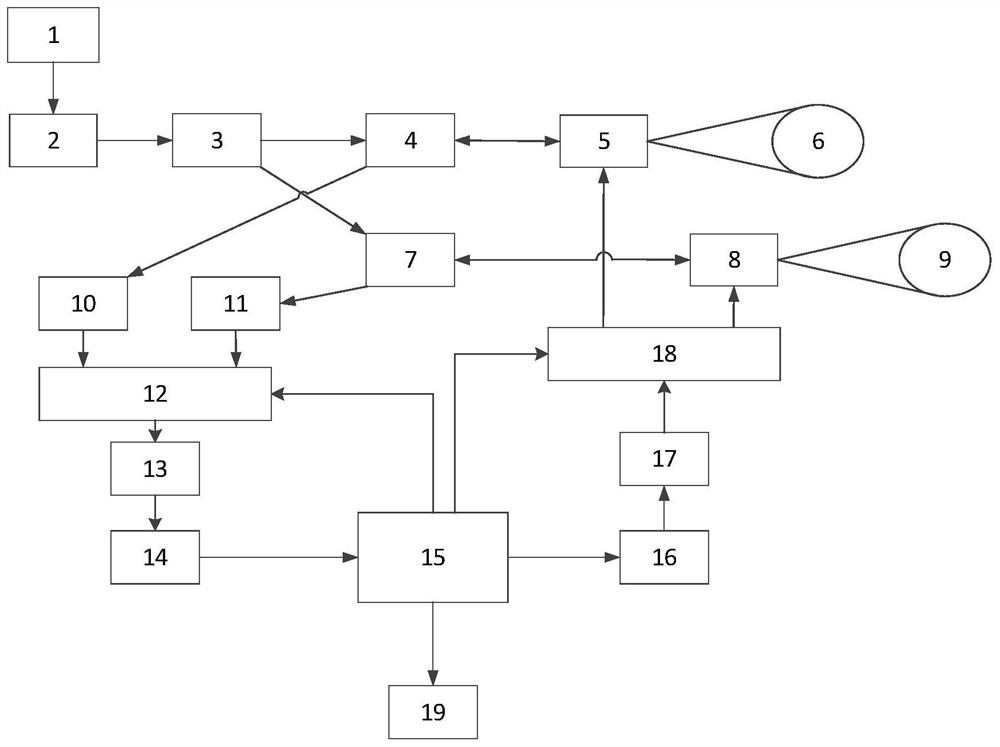

[0025] Such as figure 1 As shown, this embodiment provides a miniaturized fiber optic gyroscope based on time division multiplexing, including a light source 2, a coupling unit, a plurality of detection units, and a first multi-channel switch 12, a preamplifier 13, and an AD converter connected in sequence 14, signal processor 15, DA converter 16, post-amplifier 17 and the second multi-channel switch 18, the first multi-channel switch 12 also connects a plurality of detection units and signal processor 15 respectively, the second multi-channel switch 18 also Respectively connect a plurality of detection units and the signal processor 15, and the coupling unit is respectively connected with a plurality of detection units;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap