Thin double-layer trunnion box structure

A trunnion box and double-layer technology, which is applied in the field of thin double-layer trunnion box structure, can solve the problem of insufficient connection between the thin trunnion box and the drum body, and achieve the goal of ensuring force, optimizing force, and ensuring mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

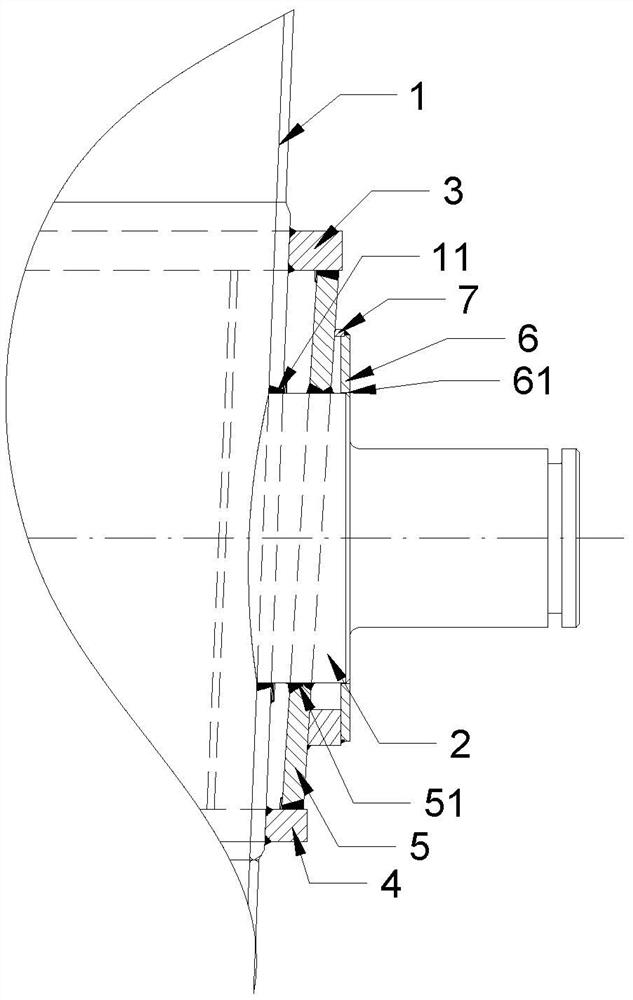

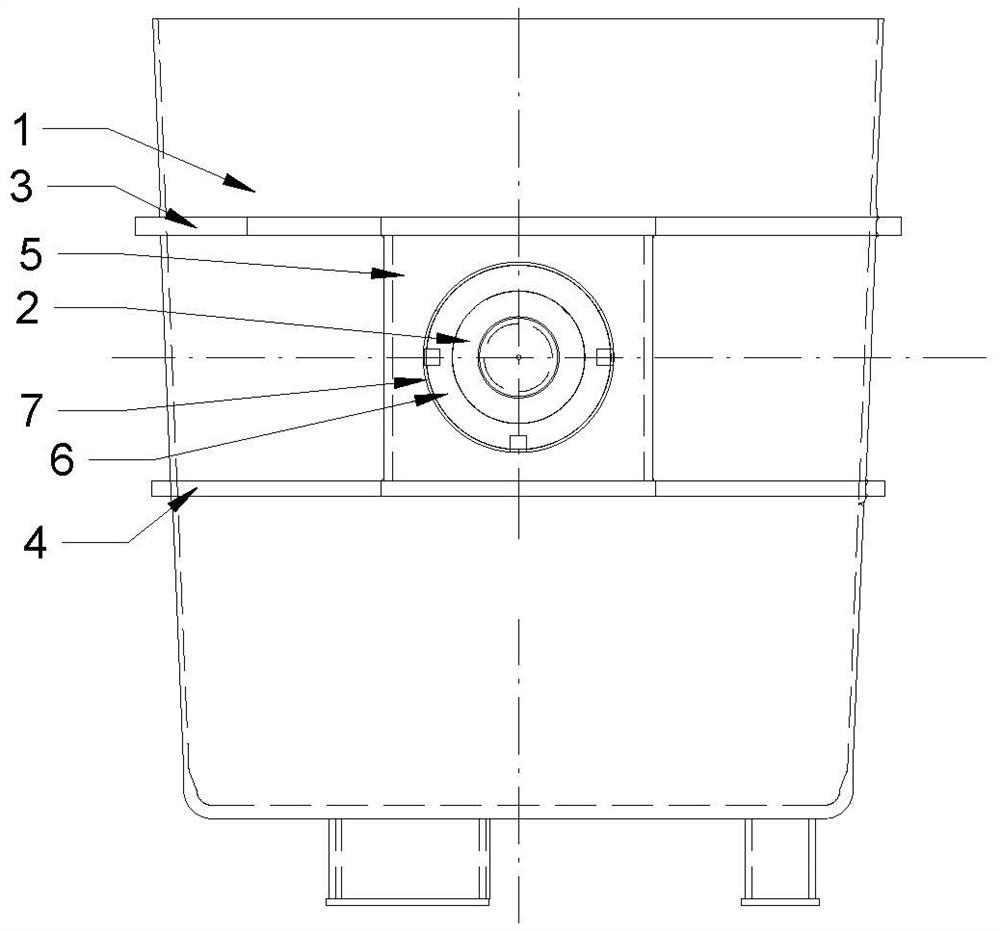

[0015] A thin double-layer trunnion box structure, which includes a barrel body 1 and trunnion boxes 2 arranged on both sides of the barrel body 1, the upper and lower sides of the trunnion box 2 are respectively provided with an upper waist hoop 3, a lower waist hoop 4, and an upper waist hoop 4. The hoop 3 and the lower waist hoop 4 are fixed on the barrel body 1 respectively; the upper waist hoop 3 and the lower waist hoop 4 are welded with a vertical plate 5, and the front side of the vertical plate 5 is provided with a panel 6, and the panel 6 is fixed to the vertical plate through the ring plate 7 5; the limit hole 61 passing through the center of the panel 6 of th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap